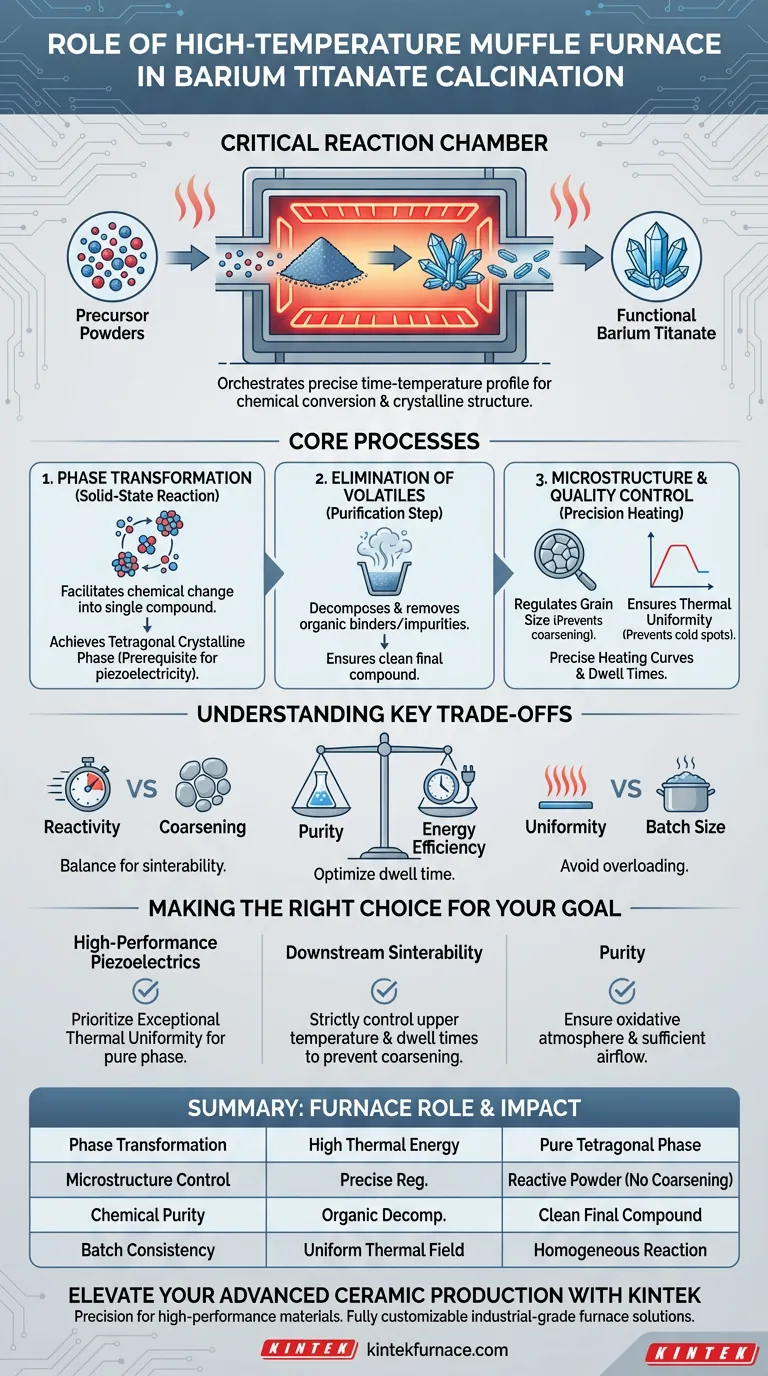

An industrial-grade high-temperature muffle furnace acts as the critical reaction chamber for transforming raw chemical mixtures into functional Barium Titanate. It provides a strictly controlled thermal environment that drives solid-state reactions, converting precursor powders into the specific crystalline phase required for high-performance piezoelectric applications.

The muffle furnace does more than simply heat the material; it orchestrates the precise time-temperature profile required to chemically convert precursors into a pure Barium Titanate phase. This process establishes the crystallinity and grain structure that define the material's final electrical and mechanical properties.

The Mechanism of Phase Transformation

Facilitating Solid-State Reactions

The primary function of the furnace is to provide the energy needed for a solid-state reaction. In this environment, the physically mixed raw powders undergo a chemical change to become a single, unified compound.

This reaction converts the initial mixture into the specific Barium Titanate phase. Without this stable thermal input, the material would remain a mixture of unreacted oxides rather than a functional ceramic powder.

Achieving the Tetragonal Crystalline Phase

For Barium Titanate to exhibit piezoelectric properties, it must possess a specific crystal structure. The furnace drives the powder into a stable tetragonal crystalline phase.

This phase transformation is the prerequisite for the material's ferroelectric capabilities. If the furnace fails to reach or maintain the correct temperature, the powder may remain in a non-functional cubic phase or contain secondary impurities.

Elimination of Volatiles

The calcination process also serves as a purification step. The high-temperature environment effectively decomposes and removes residual organic components, surfactants, or volatile impurities left over from the mixing process.

Controlling Microstructure and Quality

Regulating Grain Size

Temperature control is directly linked to particle morphology. The furnace must maintain a balance that ensures complete reaction without causing grain coarsening.

If the temperature is too high or uncontrolled, particles may grow too large. Controlling the grain size at this stage is vital for the reactivity of the powder during subsequent processing steps.

Ensuring Thermal Uniformity

An industrial muffle furnace is designed to provide a uniform thermal field distribution. This ensures that the powder in the center of the batch undergoes the exact same reaction as the powder at the edges.

Uniformity prevents "cold spots" that could lead to incomplete reactions. A uniform thermal history is essential for creating a homogeneous, single-phase material.

Precise Heating Curves

The furnace allows manufacturers to program specific heating rates and dwell times. For example, a protocol might involve ramping to 800°C and holding for a set duration to refine the crystal structure.

These parameters determine the completion of the reaction. Precise control over the "dwell time" ensures the phase transformation finishes completely before the cooling cycle begins.

Understanding the Trade-offs

Reactivity vs. Coarsening

There is a delicate trade-off between reaction completeness and particle size. Higher temperatures drive the reaction faster but risk growing the grains too large, which reduces the powder's sinterability later.

Purity vs. Energy Efficiency

Longer dwell times ensure the total removal of organic impurities and complete phase formation. However, extending the cycle beyond what is chemically necessary wastes energy and reduces manufacturing throughput.

Uniformity vs. Batch Size

Increasing the batch size in an industrial furnace can challenge thermal uniformity. If the furnace is overloaded, the center of the powder bed may not reach the target temperature, leading to inconsistent piezoelectric performance in the final product.

Making the Right Choice for Your Goal

To optimize the calcination of Barium Titanate, you must align your furnace parameters with your specific material requirements.

- If your primary focus is High-Performance Piezoelectrics: Prioritize a furnace with exceptional thermal uniformity to ensure the entire batch achieves the pure tetragonal phase without secondary impurities.

- If your primary focus is Downstream Sinterability: strictly control the upper temperature limits and dwell times to prevent grain coarsening, ensuring the powder remains reactive for final densification.

- If your primary focus is Purity: Ensure the furnace is capable of maintaining an oxidative atmosphere with sufficient airflow to fully evacuate decomposed organic binders and volatiles.

The muffle furnace is not just a heat source; it is the tool that defines the chemical identity and physical potential of your Barium Titanate powder.

Summary Table:

| Process Objective | Furnace Role | Impact on Material |

|---|---|---|

| Phase Transformation | High Thermal Energy | Converts precursors into pure tetragonal crystalline phase |

| Microstructure Control | Precise Temperature Regulation | Prevents grain coarsening to maintain powder reactivity |

| Chemical Purity | Organic Decomposition | Removes volatiles and surfactants for a clean final compound |

| Batch Consistency | Uniform Thermal Field | Ensures homogeneous reaction across the entire powder bed |

Elevate Your Advanced Ceramic Production with KINTEK

Precision is the foundation of high-performance piezoelectric materials. At KINTEK, we understand that Barium Titanate calcination requires more than just heat—it requires a strictly controlled thermal environment.

Backed by expert R&D and world-class manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces. All our systems are fully customizable to meet your unique temperature profiles and uniformity requirements, ensuring your powders achieve the perfect grain structure and chemical identity every time.

Ready to optimize your material properties? Contact us today to speak with a technical specialist about our industrial-grade furnace solutions.

Visual Guide

References

- Effect of Beam Power on Intermetallic Compound Formation of Electron Beam-Welded Cu and Al6082-T6 Dissimilar Joints. DOI: 10.3390/eng6010006

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a muffle furnace play in NHoHMM fabrication? Mastering Precision Solid-State Dewetting

- What maintenance considerations are important for muffle furnaces? Ensure Accuracy, Safety, and Longevity

- What is the purpose of 300°C carbonization in a muffle furnace for carbon aerogels? Enhance Oil-Water Separation

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What role does a muffle furnace play in the SHS of lithium orthosilicate? Efficient Thermal Ignition Explained

- What role does a muffle furnace play in the solid-state reaction synthesis of Dy4T1-xGa12? Achieve Pure Alloy Phases

- What are the primary applications of a box furnace? Essential Uses in Heat Treatment and Material Processing

- Why are muffle furnaces considered versatile in industrial and laboratory settings? Unlock Precision Heating for Diverse Applications