The fundamental difference in atmosphere control is that a muffle furnace is designed to operate with a sealed, precisely managed atmosphere, while a drying oven functions by continuously circulating ambient air. Muffle furnaces are closed systems used for material transformation, often using inert gases to prevent reactions like oxidation. In contrast, drying ovens are open systems built specifically for moisture removal.

A muffle furnace is a precision instrument for altering materials at high temperatures in a controlled or inert environment. A drying oven is a bulk processing tool designed for one job: removing moisture from a substance using heated, circulating air.

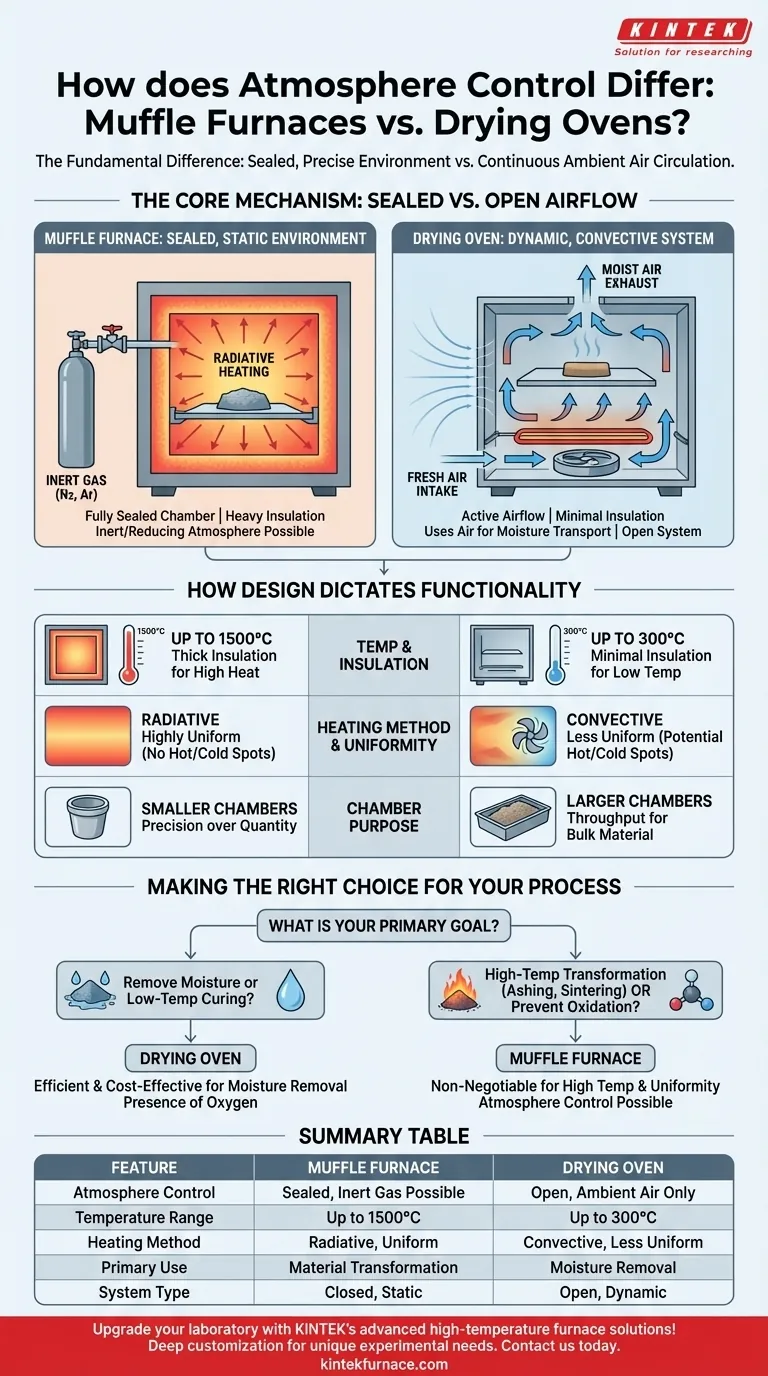

The Core Mechanism: Sealed vs. Open Airflow

The most significant distinction comes down to how each device handles air. This single design principle dictates their function, capabilities, and limitations.

Muffle Furnaces: A Sealed, Static Environment

A muffle furnace is constructed as a fully sealed chamber during operation. Heavy insulation and airtight doors prevent any exchange with the outside air.

This sealed design is intentional. It creates a static environment where heat is distributed evenly, primarily through radiation from the heating elements.

Crucially, this allows for atmosphere control. An operator can purge the ambient air and introduce a specific gas, such as nitrogen or argon, to create an inert or reducing atmosphere for sensitive processes.

Drying Ovens: A Dynamic, Convective System

A drying oven operates on the principle of active airflow. It is an open system by design, featuring intake and exhaust vents.

A fan circulates fresh, ambient air across heating elements. This hot, dry air then flows over the material inside, absorbing moisture.

The resulting moist air is then vented out of the chamber, completing a continuous cycle. The goal is not to control the atmospheric composition but to use air as a medium for moisture transport.

How Design Dictates Atmosphere and Temperature

The intended use—material transformation versus simple drying—drives every aspect of the equipment's design, from its temperature range to its physical construction.

Insulation and Temperature Range

Muffle furnaces are lined with thick, heavy insulation to contain extreme heat. This enables them to reach very high temperatures, often up to 1500°C, required for processes like ashing, sintering, or annealing.

Drying ovens have minimal insulation because their purpose is low-temperature moisture removal. They typically operate at a much lower maximum temperature, usually around 300°C.

Heating Method and Uniformity

The sealed, static chamber of a muffle furnace allows for highly uniform heat distribution. Without forced airflow, hot and cold spots are virtually eliminated, ensuring every part of the sample receives the same thermal treatment.

Drying ovens rely on convection, where a fan blows heated air. This inherently creates less uniform heating, with potential for hot and cold spots depending on the airflow pattern and chamber loading.

Chamber Design and Purpose

Muffle furnaces typically have smaller chambers to ensure precise temperature control and minimize the volume of gas needed for atmosphere management. They are built for precision over quantity.

Drying ovens often feature much larger chambers to accommodate bulk materials or large batches. Their design prioritizes throughput for moisture removal over the pinpoint precision of a furnace.

Understanding the Trade-offs

Neither tool is universally superior; they are optimized for different tasks, and choosing the wrong one leads to failed processes and wasted resources.

The Cost of Control (Muffle Furnace)

The precision of a muffle furnace comes at a cost. They are significantly more expensive to purchase and operate due to their heavy construction and high energy consumption.

Their smaller volume limits batch sizes, and their sealed nature makes them inefficient for removing large amounts of moisture or other volatiles, as there is no mechanism for venting.

The Limits of Simplicity (Drying Oven)

A drying oven's simplicity is its weakness for advanced applications. The constant presence of oxygen from ambient air will ruin any process that is sensitive to oxidation at elevated temperatures.

Furthermore, their lower temperature limit and non-uniform heating make them completely unsuitable for applications that require precise thermal ramping, soaking, or consistent material property changes.

Making the Right Choice for Your Process

Your selection depends entirely on the intended transformation of your material. Understanding the goal of your thermal process is the most critical step.

- If your primary focus is removing moisture or curing at low temperatures: A drying oven is the efficient, correct, and cost-effective choice.

- If your primary focus is high-temperature material transformation (e.g., ashing, annealing, sintering): A muffle furnace is non-negotiable for its temperature capability and uniform heating.

- If your primary focus is preventing oxidation or reaction with air at any temperature: A muffle furnace with atmosphere control is the only suitable option.

Choosing between these tools is not about which is "better," but about precisely matching the equipment's fundamental design to your specific scientific or industrial goal.

Summary Table:

| Feature | Muffle Furnace | Drying Oven |

|---|---|---|

| Atmosphere Control | Sealed, inert gas possible | Open, ambient air only |

| Temperature Range | Up to 1500°C | Up to 300°C |

| Heating Method | Radiative, uniform | Convective, less uniform |

| Primary Use | Material transformation | Moisture removal |

| System Type | Closed, static | Open, dynamic |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure