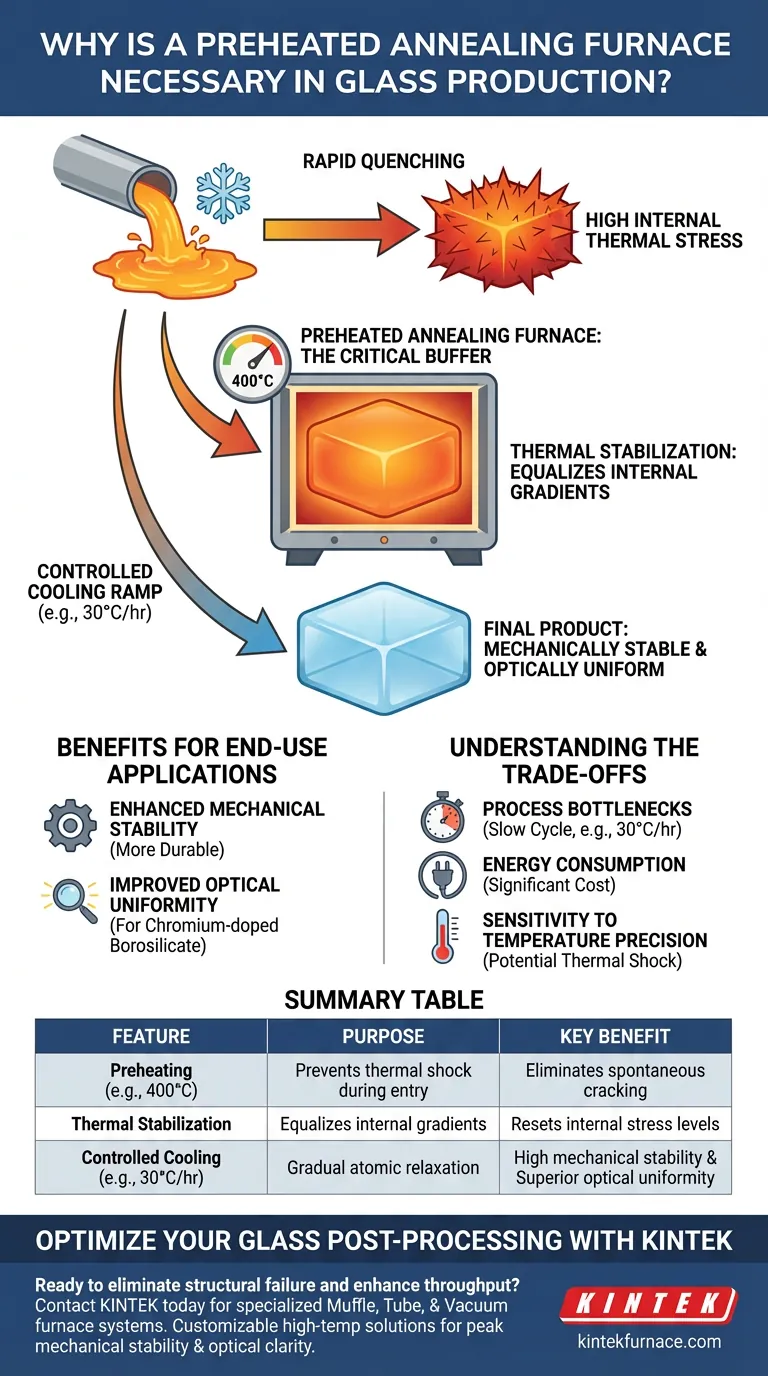

A preheated annealing furnace serves as a critical buffer against catastrophic structural failure. In the production of glass, specifically materials like chromium-doped borosilicate glass, the rapid quenching phase creates significant internal thermal stress. Without the controlled environment of a preheated furnace, the glass is liable to crack spontaneously if cooled directly to room temperature.

The annealing process functions as a controlled release valve for internal tension. By maintaining a specific temperature and cooling the material at a remarkably slow rate, the furnace eliminates residual stresses to ensure the glass is both mechanically stable and optically uniform.

The Physics of Thermal Stress

The Consequence of Rapid Quenching

When glass is produced, it often undergoes a rapid quenching process. While necessary for certain formation steps, this sudden change accumulates dangerous levels of internal thermal stress.

The Risk of Spontaneous Cracking

If this stressed material is allowed to cool immediately to room temperature, the internal tension exceeds the material's strength. This results in spontaneous cracking, rendering the sample useless.

The Function of the Preheated State

A preheated furnace mitigates this shock. By introducing the glass into an environment already heated to a specific target—such as 400°C—you prevent the thermal shock that occurs in ambient air.

The Mechanics of the Annealing Process

Stabilizing the Material

Once inside the preheated furnace, the glass is held at a stable temperature. This allows the thermal gradients within the glass to equalize, effectively "resetting" the internal stress levels.

The Importance of Slow Cooling

The most critical phase is the cooling ramp. Rather than cooling naturally, the furnace lowers the temperature at a strictly controlled rate, such as 30°C per hour.

Releasing Residual Stress

This gradual reduction allows the atomic structure of the glass to relax without forming new stress points. This controlled descent is the primary mechanism for releasing residual internal stresses.

Benefits for End-Use Applications

Enhancing Mechanical Stability

Glass that has been properly annealed is significantly more durable. By removing internal tension, the material achieves greater mechanical stability, making it less prone to fracture during handling or operation.

Improving Optical Uniformity

Stress affects how light travels through glass. For applications involving chromium-doped borosilicate glass, removing these stresses is vital for achieving high optical uniformity and clarity.

Understanding the Trade-offs

Process Bottlenecks

The annealing process is inherently slow. A cooling rate of 30°C per hour means a cycle can take many hours to complete, potentially creating a throughput bottleneck in production.

Energy Consumption

Maintaining a furnace at 400°C and controlling a slow ramp-down requires significant energy. This adds to the operational cost of the post-processing phase compared to air cooling.

Sensitivity to Temperature Precision

The furnace must be preheated accurately. If the temperature differential between the quenched glass and the furnace is too large, the thermal shock the process is meant to prevent may occur anyway.

Making the Right Choice for Your Goal

Whether you are prioritizing throughput or absolute material integrity, understanding the role of annealing is key.

- If your primary focus is Mechanical Durability: You must strictly adhere to the slow cooling protocol (e.g., 30°C/hr) to ensure all internal tension is resolved.

- If your primary focus is Optical Quality: Prioritize the uniformity of the furnace temperature to prevent refractive inconsistencies caused by residual stress.

By treating the annealing furnace not as an accessory, but as a fundamental component of the glass structure, you ensure a reliable, high-performance final product.

Summary Table:

| Feature | Purpose | Key Benefit |

|---|---|---|

| Preheating (e.g., 400°C) | Prevents thermal shock during entry | Eliminates spontaneous cracking |

| Thermal Stabilization | Equalizes internal gradients | Resets internal stress levels |

| Controlled Cooling (e.g., 30°C/hr) | Gradual atomic relaxation | High mechanical stability |

| Stress Removal | Eliminates residual tension | Superior optical uniformity |

Optimize Your Glass Post-Processing with KINTEK

Don't let internal thermal stress compromise your material quality. Backed by expert R&D and precision manufacturing, KINTEK offers specialized Muffle, Tube, and Vacuum furnace systems designed to handle the rigorous slow-cooling requirements of glass annealing. Whether you need a standard solution or a customizable high-temp furnace for unique laboratory needs, our equipment ensures your chromium-doped borosilicate glass and other materials achieve peak mechanical stability and optical clarity.

Ready to eliminate structural failure and enhance throughput? Contact KINTEK today to discuss your customized furnace solution!

Visual Guide

References

- Fathy Abdel-Wahab, Heba Abdelmaksoud. Investigation of oxygen defects in chromium-doped borosilicate glass co-doped with alkali metal (Na2O) and transition metal (ZnO) for photonic applications. DOI: 10.1007/s00339-024-08114-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What effects does a reducing atmosphere have on ceramic wares during firing? Unlock Deep Colors and Unique Finishes

- What advantages does an inert oven provide? Achieve Precise Control for Sensitive Materials

- What is the structure of a protective atmosphere box furnace? Unlock Precise Heat Treatment with Controlled Environments

- How is an atmosphere box furnace utilized in research on material properties? Unlock Precision in Material Science

- What types of environments can the protective atmosphere box furnace be used in? Essential for Oxidation-Free High-Temp Processes

- How does atmosphere control affect defect formation in graphitic carbon nitride? Master Atmosphere Engineering

- What role do cooling systems play in retort furnaces? Master Material Properties with Precision Cooling

- What are the risk mitigation strategies for atmosphere furnace operation? Ensure Safe and Efficient Lab Processes