In any high-temperature retort furnace, the cooling system is not a passive afterthought but an active and critical tool for process control. Its primary role is to manage the cooling rate of the material after the heating cycle, which is essential for dictating the final microstructure and, consequently, the physical properties like hardness, ductility, and internal stress.

The cooling system's function extends far beyond simply bringing the material back to room temperature. It is a deliberate engineering control that "locks in" the desired material characteristics, making it just as crucial as the heating phase itself.

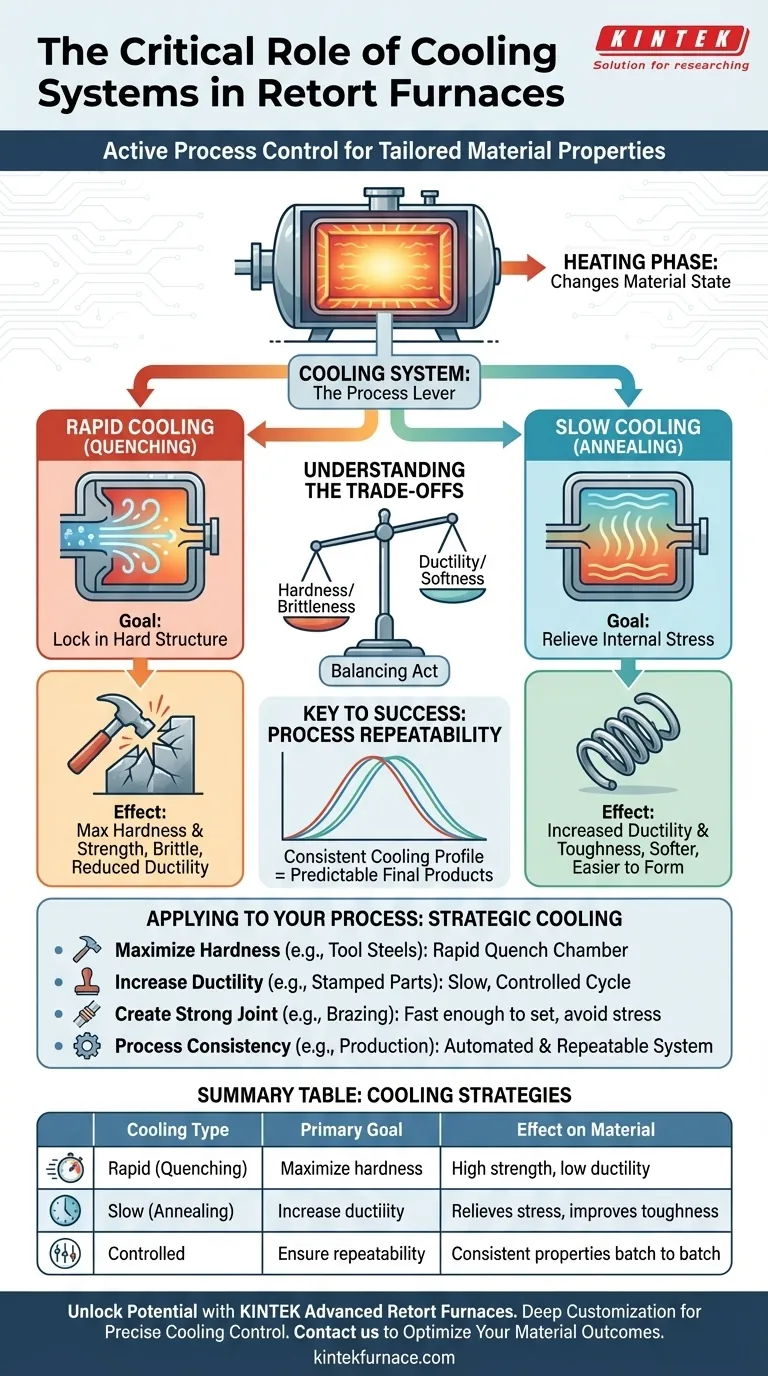

Why Controlled Cooling is a Process Lever

Thinking of a retort furnace as only a heating device is a common oversight. The reality is that the thermal treatment is a two-part process: heating changes the material's state, and cooling determines the final form that state takes.

Defining Material Microstructure

Heat treatment alters the atomic or crystalline arrangement within a material, known as its microstructure. The speed at which the material cools from its high-temperature state determines how those atoms arrange themselves as they lose energy. This final arrangement dictates the material's mechanical properties.

The Goal of Rapid Cooling (Quenching)

In processes like hardening, the goal is to cool the material so quickly that the atoms don't have time to rearrange into their softest, most stable state. This process, often called quenching, traps the material in a harder, more brittle microstructure. A fast-cooling chamber in a retort furnace facilitates this by using inert gas or other media to extract heat rapidly.

The Goal of Slow Cooling (Annealing)

Conversely, in processes like annealing, the material is cooled very slowly and deliberately. This allows the internal atomic structure to rearrange in a way that relieves internal stresses built up during manufacturing. The result is a softer, more ductile, and less brittle material.

Understanding the Trade-offs

The choice of cooling rate is never without consequences. It is a balancing act between competing material properties, and understanding these trade-offs is fundamental to successful heat treatment.

Hardness vs. Brittleness

Rapidly cooling a metal alloy will almost always increase its hardness and strength. However, this comes at the cost of reduced ductility, making the material more brittle and susceptible to fracturing under impact or stress.

Ductility vs. Softness

Slowly cooling a material increases its ductility and toughness, making it easier to machine or form. The trade-off is a decrease in hardness and tensile strength, making the material softer.

Process Repeatability

The core challenge is not just achieving a fast or slow cool-down, but achieving the exact same cooling profile every time. An integrated cooling system ensures that every part in a batch, and every subsequent batch, experiences the same thermal history, leading to consistent and predictable final products.

How to Apply This to Your Process

The ideal cooling strategy is entirely dependent on the desired outcome for your material or component.

- If your primary focus is maximizing hardness and strength (e.g., for tool steels): Your process requires a retort furnace equipped with a rapid quenching or fast-cooling chamber.

- If your primary focus is increasing ductility and relieving internal stress (e.g., for annealing stamped parts): Your process needs a slow, highly controlled, and programmable cooling cycle.

- If your primary focus is creating a strong joint (e.g., for brazing): You need a cooling rate that is fast enough to set the brazing alloy properly without introducing excessive thermal stress into the components.

- If your primary focus is process consistency in a production environment: You must select a furnace with an automated and repeatable cooling system to eliminate process variability.

Ultimately, mastering the cooling phase gives you direct control over the performance and quality of your final product.

Summary Table:

| Cooling Type | Primary Goal | Effect on Material |

|---|---|---|

| Rapid (Quenching) | Maximize hardness | Increases strength, reduces ductility |

| Slow (Annealing) | Increase ductility | Relieves stress, improves toughness |

| Controlled | Ensure repeatability | Achieves consistent properties batch to batch |

Unlock the full potential of your heat treatment processes with KINTEK's advanced retort furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise cooling control to meet your unique experimental needs—enhancing hardness, ductility, and consistency. Contact us today to discuss how our expertise can optimize your material outcomes and boost efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments