Precise temperature control is the primary safeguard against structural failure during the manufacturing process. A muffle furnace is required to maintain a strictly controlled 50°C environment for extended periods (up to 8 hours), allowing the ammonium bicarbonate space holder to sublimate slowly rather than decompose rapidly.

Core Takeaway The structural integrity of porous titanium alloy hinges on the rate of space holder removal. Precise thermal regulation prevents the rapid expansion of gases, thereby avoiding internal pressure buildup that leads to micro-cracks and compromised mechanical stability.

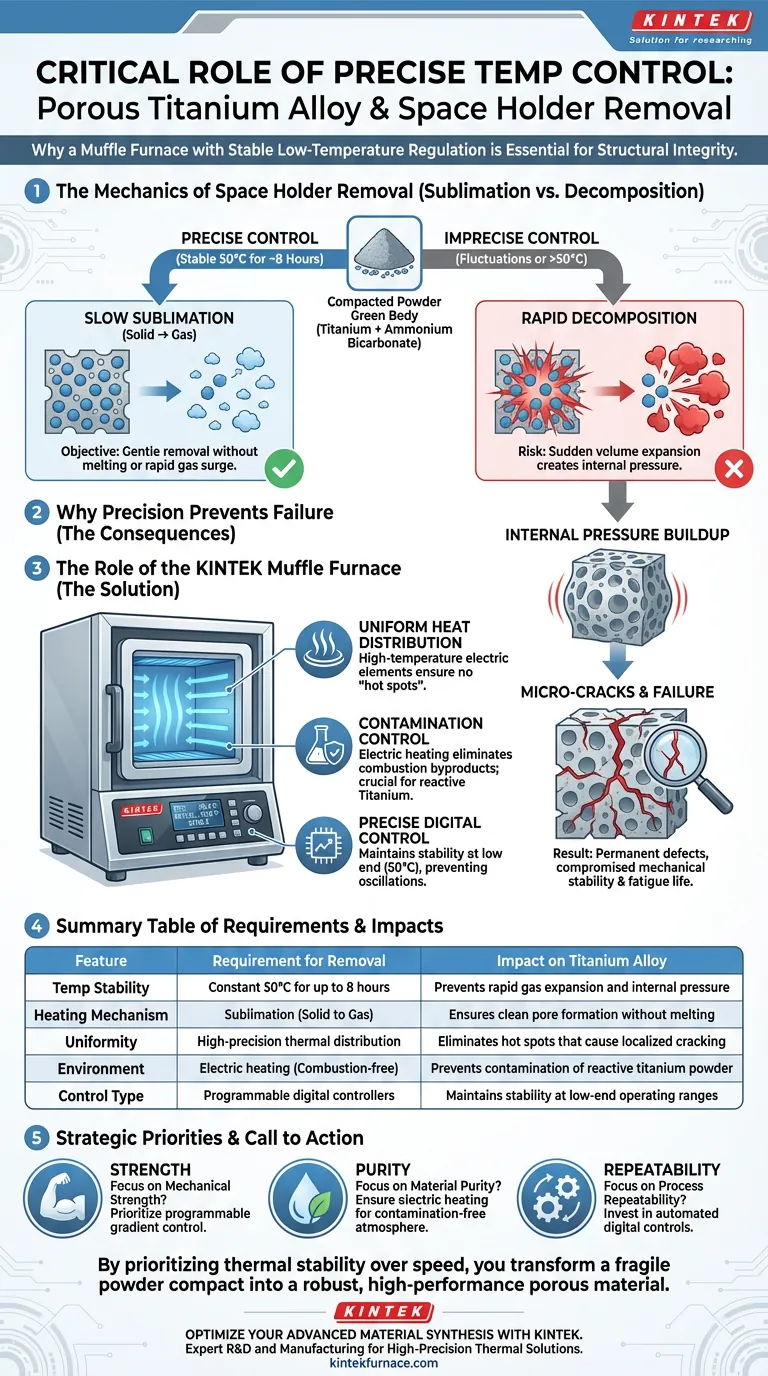

The Mechanics of Space Holder Removal

The Sublimation Process

The production of porous titanium alloy often utilizes ammonium bicarbonate as a temporary space holder.

To create the desired pore structure, this material must be removed completely before the final sintering of the metal.

The goal is sublimation, where the solid turns directly into gas, rather than melting.

The Necessity of Low Temperatures

Contrary to the high temperatures usually associated with furnaces, this specific stage requires a stable, low-temperature environment of 50°C.

This process is slow and deliberate, often requiring up to 8 hours to complete.

Standard heating equipment often struggles to maintain such low temperatures with the necessary stability, making specialized control essential.

Why Precision Prevents Failure

Controlling Decomposition Rates

If the temperature rises too quickly or fluctuates, the ammonium bicarbonate decomposes rapidly.

This rapid decomposition generates a sudden surge of gas volume within the compacted metal powder.

Avoiding Internal Pressure

The metal powder at this stage is not yet fully sintered and lacks high mechanical strength.

A sudden release of gas creates significant internal pressure buildup inside the green body (the compacted form).

Preventing Micro-Cracks

If this internal pressure exceeds the strength of the compacted powder, it forces the material apart.

This results in micro-cracks within the titanium structure.

These microscopic defects permanently compromise the mechanical stability and fatigue life of the final alloy.

The Role of the Muffle Furnace

Uniform Heat Distribution

Modern muffle furnaces utilize high-temperature electric heating elements to ensure excellent temperature uniformity across the chamber.

This prevents "hot spots" that could trigger localized rapid decomposition in parts of the sample while other parts remain cool.

Contamination Control

Because muffle furnaces use electric heating rather than combustion, they eliminate combustion byproducts.

This guarantees a contamination-free environment, which is critical for reactive metals like titanium that are sensitive to impurities.

Understanding the Trade-offs

Time vs. Throughput

The strict requirement for a slow, 8-hour heating cycle at 50°C creates a significant bottleneck in production speed.

Attempting to accelerate this process by raising the temperature will almost invariably lead to structural defects.

Equipment Sensitivity

While muffle furnaces are excellent for uniformity, maintaining precise control at the very low end of their operating range (50°C) requires high-quality digital or programmable controllers.

Older or less sophisticated furnaces may oscillate around the setpoint, risking the very instability the process seeks to avoid.

Making the Right Choice for Your Goal

To ensure the success of your porous titanium alloy production, consider these strategic priorities:

- If your primary focus is Mechanical Strength: Prioritize a furnace with programmable gradient control to ensure the temperature never spikes, preventing micro-crack formation.

- If your primary focus is Material Purity: Ensure your furnace utilizes electric heating elements to maintain a contamination-free atmosphere during the long sublimation phase.

- If your primary focus is Process Repeatability: Invest in digital controls that can automate the 8-hour low-temperature profile to reduce operator error.

By prioritizing thermal stability over speed, you transform a fragile powder compact into a robust, high-performance porous material.

Summary Table:

| Feature | Requirement for Space Holder Removal | Impact on Titanium Alloy |

|---|---|---|

| Temperature Stability | Constant 50°C for up to 8 hours | Prevents rapid gas expansion and internal pressure |

| Heating Mechanism | Sublimation (Solid to Gas) | Ensures clean pore formation without melting |

| Uniformity | High-precision thermal distribution | Eliminates hot spots that cause localized cracking |

| Environment | Electric heating (Combustion-free) | Prevents contamination of reactive titanium powder |

| Control Type | Programmable digital controllers | Maintains stability at low-end operating ranges |

Optimize Your Advanced Material Synthesis with KINTEK

Precise thermal regulation is the difference between structural failure and a high-performance alloy. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the most stringent laboratory requirements.

Whether you need delicate low-temperature sublimation or high-temp sintering, our customizable furnaces ensure the stability and purity your research demands.

Ready to elevate your lab's capabilities? Contact our technical experts today to find the perfect thermal solution for your unique needs.

Visual Guide

References

- Juan Villemur, E. Gordo. Fabrication and Coating of Porous Ti6Al4V Structures for Application in PEM Fuel Cell and Electrolyzer Technologies. DOI: 10.3390/ma17246253

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the primary functions of laboratory resistance furnaces in lead refining? Achieve 700°C Thermal Precision

- What should be checked after unpacking a muffle furnace? Ensure Safe Setup and Optimal Performance

- How do laboratory high-temperature furnaces assist in determining the annealing temperatures? Replicate Ancient Metalwork

- How does the position of gas inlets in a muffle furnace affect the temperature distribution? Master Thermal Uniformity

- How should alkaline substances be handled in a muffle furnace? Protect Your Equipment from Corrosion

- What is the proper procedure for baking a new or long-unused muffle furnace? Ensure Longevity and Safety with Expert Tips

- What functions does a laboratory muffle furnace perform during composite film fabrication? Expert Guide

- What temperature ranges can different muffle furnace types achieve? Find the Perfect Fit for Your Lab