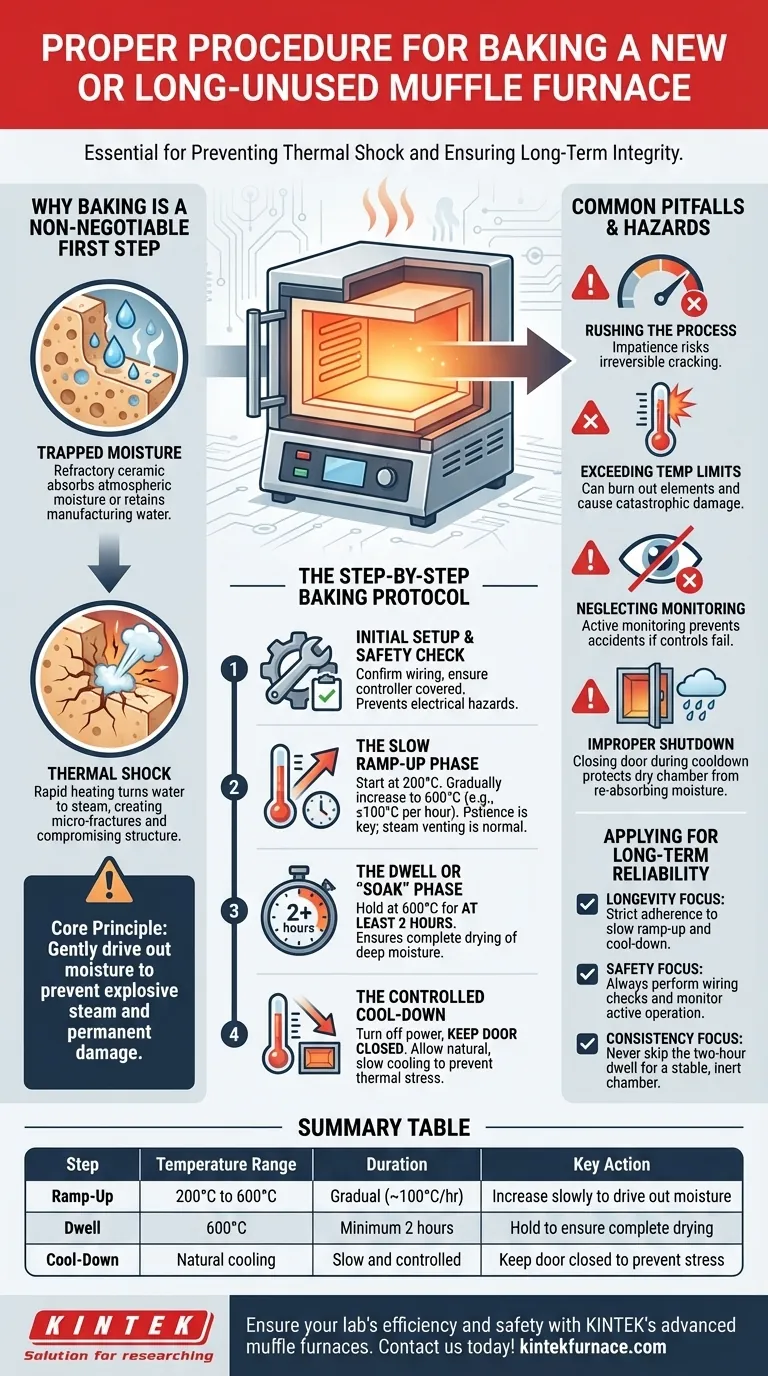

The proper procedure for baking a new or long-unused muffle furnace involves a slow and controlled heating cycle. You must gradually raise the temperature from 200°C to 600°C, then hold it at 600°C for a minimum of two hours before allowing it to cool down slowly. This process is essential to prevent thermal shock and ensure the long-term integrity of the furnace chamber.

The core principle is simple: you are gently driving out trapped moisture from the refractory materials. Rushing this process causes that moisture to turn to steam explosively on a microscopic level, creating cracks that permanently damage the furnace.

Why Baking Is a Non-Negotiable First Step

A muffle furnace's chamber is made of refractory ceramic materials. These materials are porous and readily absorb atmospheric moisture when left unused for extended periods or when new from the factory.

The Role of Trapped Moisture

The refractory insulation within your furnace contains a significant amount of water, either from the manufacturing process or absorbed from the air.

If you heat the furnace rapidly to a high operating temperature, this trapped water turns to steam. With nowhere to escape, the steam pressure builds within the ceramic material, creating micro-fractures.

The Danger of Thermal Shock

These fractures, caused by rapid heating, compromise the structural integrity and insulating properties of the furnace chamber.

While the furnace might still function, this damage can lead to shorter heating element life, poor temperature stability, and a drastically reduced operational lifespan for the entire unit.

The Step-by-Step Baking Protocol

Follow this procedure precisely to condition your furnace correctly and protect your investment. The key is patience.

Initial Setup and Safety Check

Before applying power, confirm all electrical wiring is correct and secure, as per the manufacturer's instructions. Ensure the controller housing is properly covered.

This initial check prevents electrical hazards and ensures the control system can operate as intended.

The Slow Ramp-Up Phase

Begin by setting the furnace to 200°C and allowing it to stabilize. From there, gradually increase the temperature setpoint in increments toward 600°C.

A good rule of thumb is to increase the temperature by no more than 100°C per hour. A slow, steady ramp is far more important than hitting a specific time target. During this phase, you may notice steam or vapor venting from the furnace; this is normal.

The Dwell or "Soak" Phase

Once the furnace reaches 600°C, it must be held at that temperature for at least two hours. This is known as the "dwell" or "soak" period.

This extended time at temperature ensures that all residual moisture deep within the refractory material is driven out, leaving the chamber completely dry and stable.

The Controlled Cool-Down

After the dwell period is complete, turn off the furnace power but keep the door closed.

Allowing the furnace to cool down naturally and slowly is just as critical as the ramp-up. Opening the door to cool it faster will introduce thermal stress and can cause cracking, undoing the careful work of the baking cycle.

Common Pitfalls and Operational Hazards

Beyond the initial baking, proper operation is key to the furnace's longevity. Avoiding these common mistakes is critical.

Rushing the Process

The most common failure is impatience. Attempting to speed up the ramp-up or shorten the dwell time directly risks cracking the furnace chamber, leading to irreparable damage.

Exceeding Temperature Limits

Never operate the furnace above its maximum rated temperature. Doing so can burn out the heating elements and cause severe, often catastrophic, damage to the furnace itself.

Neglecting Active Monitoring

During any heating cycle, including the initial bake-out, the furnace should be monitored. While automatic controllers are reliable, failures can occur. Active monitoring prevents accidents in the rare case of a control system malfunction.

Improper Shutdown Procedure

Always cut the main power after use. Closing the door during cooldown and storage is essential to protect the now-dry furnace chamber from re-absorbing atmospheric moisture, which would necessitate another, shorter bake-out.

Applying This for Long-Term Reliability

Your approach to furnace operation should align with your primary goal, whether it's protecting the equipment or ensuring the safety of your lab.

- If your primary focus is equipment longevity: Adhere strictly to the slow ramp-up and slow, door-closed cool-down procedures to prevent thermal shock.

- If your primary focus is operational safety: Always perform initial wiring checks and actively monitor the furnace during operation to prevent accidents from control failure or overheating.

- If your primary focus is consistent results: Never skip the two-hour dwell phase, as this guarantees a completely dry and inert chamber for future experiments.

Treating your muffle furnace with this initial care establishes the foundation for years of reliable and safe operation.

Summary Table:

| Step | Temperature Range | Duration | Key Action |

|---|---|---|---|

| Ramp-Up | 200°C to 600°C | Gradual (e.g., 100°C/hour) | Increase slowly to drive out moisture |

| Dwell | 600°C | Minimum 2 hours | Hold to ensure complete drying |

| Cool-Down | Natural cooling | Slow and controlled | Keep door closed to prevent stress |

Ensure your lab's efficiency and safety with KINTEK's advanced muffle furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to learn how our products can enhance your processes and protect your investments!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating