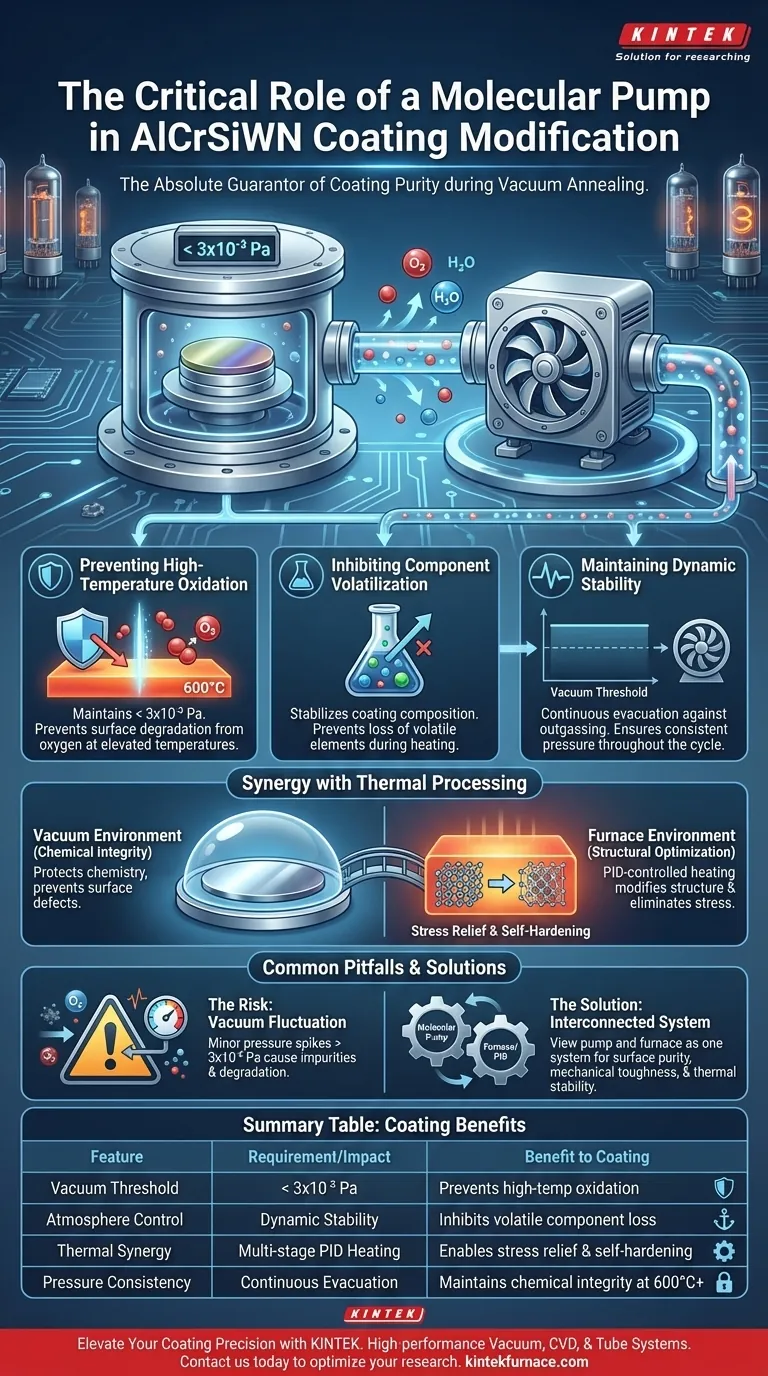

The molecular pump unit is the absolute guarantor of coating purity. It is critical for the modification of AlCrSiWN coatings because it maintains a dynamic vacuum level below 3x10^-3 Pa throughout the annealing cycle. This specific pressure threshold prevents the coating from oxidizing or losing volatile components at high temperatures, ensuring the material's chemical integrity remains intact while its structure is optimized.

By sustaining a high-vacuum environment, the molecular pump allows the annealing process to alter the physical structure of the coating without degrading its chemical surface. It serves as the defensive barrier against high-temperature oxidation during the crucial heating phase.

The Role of High Vacuum in Coating Modification

Preventing High-Temperature Oxidation

The primary danger to AlCrSiWN coatings during annealing is exposure to oxygen at elevated temperatures.

At operating temperatures such as 600°C, standard atmospheric conditions would cause immediate surface degradation. The molecular pump actively removes gas molecules to prevent these chemical reactions.

Inhibiting Component Volatilization

Beyond oxidation, complex coatings are susceptible to losing specific elements through volatilization when heated.

The molecular pump maintains a consistent vacuum environment that stabilizes the coating's composition. This ensures that the stoichiometry of the AlCrSiWN layer remains as intended, rather than altering due to the evaporation of volatile components.

Maintaining Dynamic Stability

The vacuum requirement is not static; it must be maintained continuously against potential outgassing.

The "dynamic" nature of the vacuum provided by the molecular pump ensures that even as the furnace heats up and materials potentially release gases, the pressure remains strictly below the 3x10^-3 Pa threshold.

Synergy with Thermal Processing

Enabling Effective Stress Relief

While the vacuum pump protects the chemistry, the furnace environment addresses the mechanical properties.

According to supplementary data, the vacuum tube furnace utilizes PID controllers to eliminate brittle residual stresses generated during deposition. The molecular pump creates the safe environment necessary for this stress relief to occur without side effects.

Facilitating Self-Hardening Effects

The annealing process is designed to induce a self-hardening effect and improve thermal stability.

These structural improvements rely on precise multi-stage heating and isothermal holding. The molecular pump ensures that these delicate thermal cycles modify the internal structure without compromising the surface quality.

Common Pitfalls to Avoid

The Risk of Vacuum Fluctuation

If the molecular pump fails to maintain the pressure below 3x10^-3 Pa, the integrity of the process is compromised.

Even minor fluctuations in pressure at 600°C can introduce impurities. This can lead to a coating that is mechanically stress-relieved but chemically degraded on the surface.

Over-Reliance on Thermal Control Alone

A precise PID controller and heating program are insufficient without the molecular pump.

Perfect thermal management cannot compensate for a poor vacuum. Without the molecular pump effectively evacuating the chamber, the precise heat treatment becomes a catalyst for oxidation rather than optimization.

Ensuring Process Success

To maximize the performance of your AlCrSiWN coatings, you must view the vacuum unit and the furnace as an interconnected system.

- If your primary focus is Surface Purity: Ensure your molecular pump is calibrated to sustain pressures strictly below 3x10^-3 Pa to prevent oxidation.

- If your primary focus is Mechanical Toughness: Verify that the vacuum stability allows the PID controller to complete the full multi-stage heating cycle to eliminate residual stresses.

- If your primary focus is Thermal Stability: Utilize the interference-free environment created by the pump to allow for prolonged isothermal holding periods.

The molecular pump is not just an accessory; it is the foundational component that makes high-temperature structural optimization possible.

Summary Table:

| Feature | Requirement/Impact | Benefit to Coating |

|---|---|---|

| Vacuum Threshold | < 3x10^-3 Pa | Prevents high-temperature oxidation |

| Atmosphere Control | Dynamic Stability | Inhibits volatile component loss |

| Thermal Synergy | Multi-stage PID Heating | Enables stress relief & self-hardening |

| Pressure Consistency | Continuous Evacuation | Maintains chemical integrity at 600°C+ |

Elevate Your Coating Precision with KINTEK

Don't let oxidation compromise your advanced material research. KINTEK’s industry-leading thermal solutions—including our high-performance Vacuum, CVD, and Tube systems—are engineered to provide the stable, high-vacuum environments required for delicate AlCrSiWN modification.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique laboratory needs. Contact us today to discover how our specialized high-temperature furnaces can optimize your material's chemical integrity and mechanical performance.

Visual Guide

References

- Feng Guo. Research on the Performance of AlCrSiWN Tool Coatings for Hardened Steel Cutting. DOI: 10.62051/ijmee.v6n2.01

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key features of a vacuum tube furnace? Master High-Temp Processing with Precision Control

- What additional features can tube furnaces have? Enhance Your Lab with Advanced Control and Customization

- How does the working temperature range affect the choice of a vertical tube furnace? Optimize Your Lab's Performance and Budget

- What is the function of a high-temperature tube furnace in Ti3AlC2 synthesis? Achieve Pure MAX Phase Precursor Powders

- How was the uneven heating problem in tubular furnaces solved? Achieve Perfect Heat Uniformity with Advanced Designs

- What temperature-related capabilities make multi zone tube furnaces valuable for research? Unlock Precision Thermal Control

- What are the primary applications of vacuum tube furnaces in materials science? Unlock Precision in Material Synthesis and Heat Treatment

- What is the primary role of a high-temperature tube furnace in Ga2O3 annealing? Optimize Your Thin Film Quality