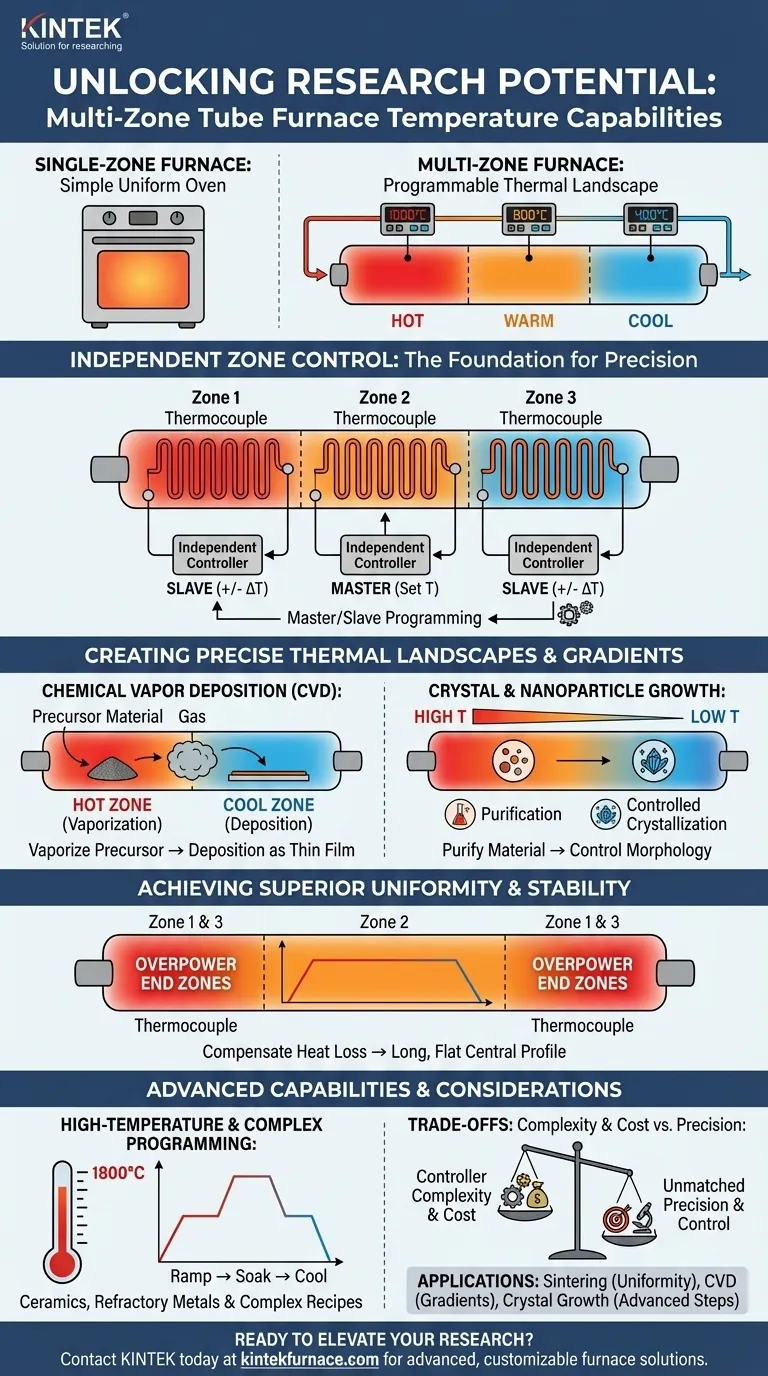

At their core, multi-zone tube furnaces are valuable because they provide researchers with independent control over multiple distinct temperature sections along a single process tube. This capability allows for the creation of precise temperature gradients—controlled variations in heat over a distance—and the stable maintenance of different temperatures simultaneously, which is impossible with a standard single-zone furnace.

A single-zone furnace acts like a simple oven, providing one uniform temperature. A multi-zone furnace, however, functions as a programmable thermal landscape, giving a researcher the power to precisely direct complex processes like material synthesis and purification that require staged heating and cooling within a single experiment.

The Foundation: Independent Zone Control

A multi-zone furnace’s primary advantage stems from its physical construction. Instead of one heater and sensor, it has several, each managed independently.

What Defines a "Zone"?

A "zone" is a discrete segment of the furnace tube that has its own dedicated heating element and thermocouple (temperature sensor). Common configurations include two, three, or even five zones, each of which can be programmed to a specific temperature setpoint.

Master/Slave Programming for Precision

Advanced controllers allow zones to operate in a "master/slave" configuration. One zone's temperature can be set as the master, with other slave zones programmed to be a specific number of degrees hotter or colder, creating a highly controlled and stable temperature difference.

Achieving Superior Uniformity

While it may seem counterintuitive, using multiple zones is often the best way to create a longer, more uniform hot zone. By slightly overpowering the end zones, you can compensate for heat loss at the tube's openings, resulting in an exceptionally stable and flat temperature profile across the central zone.

Creating Precise Thermal Landscapes

The ability to set different temperatures in adjacent zones is what enables the creation of a temperature gradient. This is not just a feature; it is a fundamental tool for advanced materials science.

The Power of Temperature Gradients

A temperature gradient is a controlled and gradual change in temperature across the length of the furnace tube. This allows a single process to involve multiple temperature-dependent steps sequentially.

Application: Chemical Vapor Deposition (CVD)

In CVD, a precursor chemical is heated in a hot zone until it vaporizes. This gas then flows into a cooler adjacent zone where the substrate is located. The temperature drop causes the gas to deposit as a solid, uniform thin film onto the substrate. This process is entirely dependent on a stable temperature gradient.

Application: Nanoparticle and Crystal Growth

Creating materials with specific crystalline structures or nanoparticle morphologies requires exquisite control over heating and cooling rates. A multi-zone furnace can create a gradient that purifies a material in one zone while precisely controlling its crystallization in another, influencing everything from particle size to uniformity.

Understanding the Trade-offs

While powerful, the capabilities of a multi-zone furnace introduce complexity and cost that must be considered.

Increased Programming Complexity

Managing multiple zones requires a more sophisticated understanding of the controller and the thermal dynamics of the system. Setting up a stable and accurate gradient is not trivial and often requires calibration and test runs.

Cost and Maintenance

Multi-zone furnaces are inherently more expensive than single-zone models due to the additional heating elements, thermocouples, and more complex power control systems. More components also mean more potential points of maintenance or failure over the furnace's lifespan.

High-Temperature Operations

These furnaces can reach very high temperatures, often up to 1200°C, 1600°C, or even 1800°C. This capability is essential for processing ceramics, refractory metals, and other advanced materials. The multi-zone control ensures these extreme temperatures are stable and precisely located where needed.

Advanced Step and Ramp Programming

Modern controllers support complex recipes with dozens of programmable segments. This allows researchers to program a series of automated steps, such as ramping up to a temperature, dwelling (soaking) for a set time, and cooling at a controlled rate, perfectly mimicking industrial-scale thermal processes.

Making the Right Choice for Your Goal

The decision to use a multi-zone furnace should be driven entirely by the thermal requirements of your experiment.

- If your primary focus is uniform heating for annealing or sintering: A high-quality single-zone furnace may be sufficient, but a multi-zone model will provide superior uniformity over a longer process area.

- If your primary focus is thin film synthesis (e.g., CVD): A multi-zone furnace is non-negotiable, as creating the required temperature gradient is fundamental to the process.

- If your primary focus is controlled crystal growth or process simulation: The advanced gradient and step-programming capabilities of a multi-zone furnace are essential for directing crystallization and replicating complex thermal cycles.

Ultimately, a multi-zone furnace provides the control to move from simply heating a material to precisely directing its transformation.

Summary Table:

| Capability | Description | Key Applications |

|---|---|---|

| Independent Zone Control | Allows setting different temperatures in distinct sections for customized thermal profiles. | Material synthesis, purification, and process simulation. |

| Temperature Gradients | Creates controlled heat variations across the tube for sequential processing steps. | Chemical Vapor Deposition (CVD), nanoparticle growth. |

| High-Temperature Operation | Supports up to 1800°C with stable, precise heating for demanding materials. | Ceramics processing, refractory metals treatment. |

| Advanced Programming | Enables complex ramp, soak, and cool cycles with master/slave configurations. | Crystal growth, thermal cycling experiments. |

Ready to elevate your research with precise thermal control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line—including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our multi-zone tube furnaces can enhance your material synthesis and purification processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation