At its core, a vacuum tube furnace is an integrated system designed for high-temperature material processing in a controlled, non-oxidizing atmosphere. Its key features include a sealed processing tube, a vacuum pump system to remove air, a high-power heating system capable of exceeding 1000°C, and a precise control system to manage temperature and pressure.

A vacuum tube furnace is not merely a high-temperature oven. Its primary value lies in its ability to create a highly controlled environment, simultaneously managing extreme heat and a near-perfect vacuum to prevent contamination and unwanted chemical reactions during material processing.

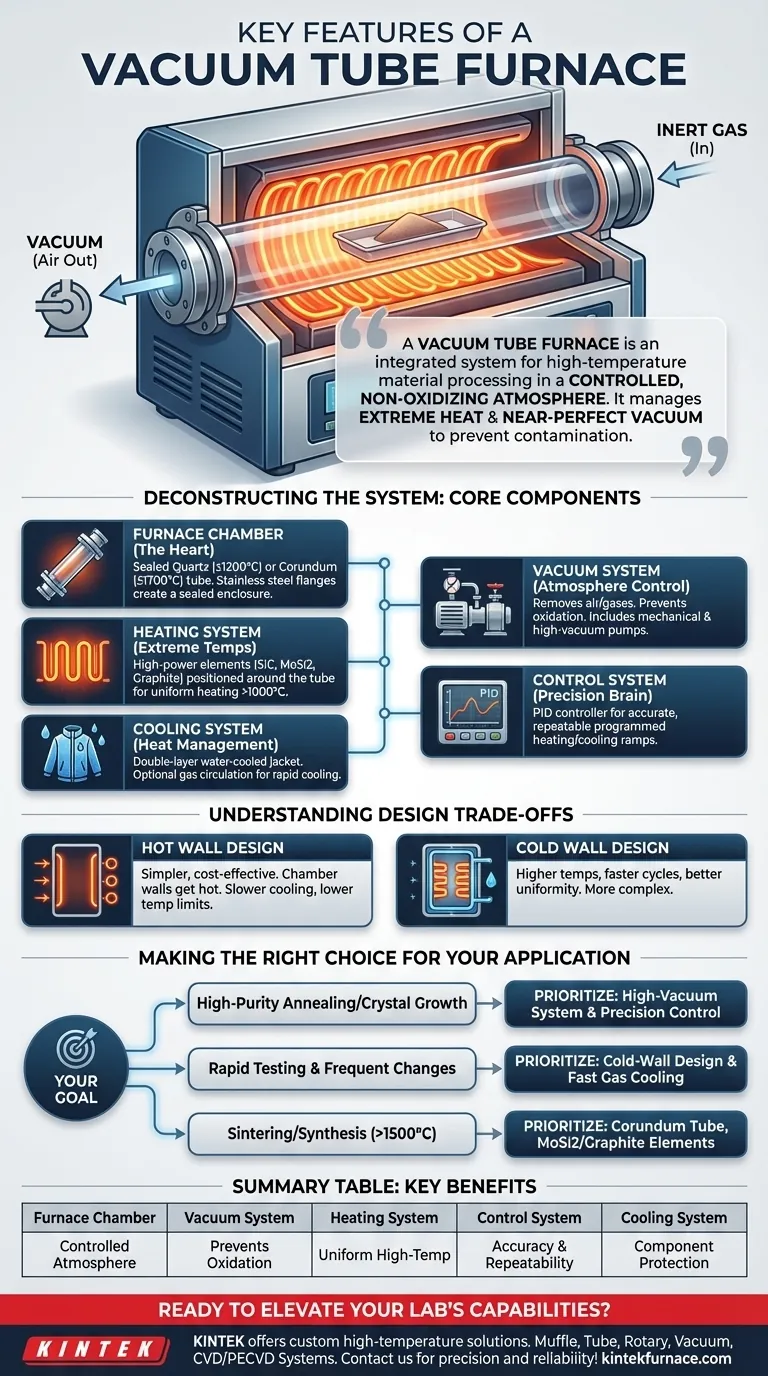

Deconstructing the System: The Core Components

To truly understand a vacuum tube furnace, you must see it as a collection of interdependent systems working in concert. Each component plays a critical role in achieving the final processing environment.

The Furnace Chamber (The Heart of the Operation)

The central working area consists of a high-purity tube, typically made of quartz for temperatures up to ~1200°C or corundum (alumina) for higher temperatures up to ~1700°C.

This tube is sealed on both ends with stainless steel flanges. This sealed enclosure is what allows for the evacuation of air and the introduction of inert gases, creating the controlled atmosphere that is the furnace's main purpose.

The Vacuum System (Controlling the Atmosphere)

This system is responsible for removing air and other gases from the furnace tube before and during the heating process. It prevents oxidation and other unwanted reactions at high temperatures.

A typical system includes one or more vacuum pumps (e.g., mechanical rotary vane pumps for rough vacuum, and molecular or diffusion pumps for high vacuum) and valves to control the flow.

The Heating System (Achieving Extreme Temperatures)

This system generates the intense heat required for processing. Heating elements are positioned around the outside of the process tube.

Common heating elements include resistance wire, silicon carbide (SiC), molybdenum disilicide (MoSi2), or graphite, depending on the maximum required temperature. The design ensures uniform heating along the length of the tube.

The Control System (Ensuring Precision and Repeatability)

This is the brain of the furnace. A temperature controller (often using a PID algorithm) reads data from a thermocouple and precisely adjusts power to the heating elements.

This system is responsible for executing programmed heating and cooling ramps, ensuring that the process is both accurate and repeatable—a critical factor in research and production environments.

The Cooling System (Managing the Heat)

A robust cooling system is essential for protecting the furnace components and the vacuum seals from the extreme temperatures.

Most furnaces use a double-layer steel shell with a water-cooling jacket. For rapid cooling of the processed material, some furnaces also incorporate a system for circulating inert gas.

Understanding the Key Design Trade-offs

Choosing or operating a vacuum tube furnace involves balancing competing priorities. The two fundamental design philosophies have significant implications for performance and use.

Hot Wall vs. Cold Wall Designs

A hot wall furnace places the heating elements outside the vacuum chamber. This is a simpler, often more cost-effective design, but the vacuum chamber itself gets hot, limiting the ultimate temperature and slowing cooling rates.

A cold wall furnace places the heating elements inside the vacuum chamber, with a water-cooled vessel wall. This design allows for much higher operating temperatures, faster heating and cooling cycles, and better temperature uniformity.

Material and Temperature Limitations

The furnace's maximum operating temperature is dictated by its weakest link. The tube material (quartz vs. corundum), heating element type, and insulation materials (e.g., ceramic fiber vs. carbon felt) all have specific temperature limits that must be respected.

Safety and Maintenance

These are not features, but operational realities. Safety interlocks for over-temperature protection and cooling water pressure are non-negotiable. Regular maintenance of the vacuum pump and sealing gaskets is critical for consistent performance and preventing costly failures.

Making the Right Choice for Your Application

Your specific goal determines which features you should prioritize.

- If your primary focus is high-purity annealing or crystal growth: Prioritize the quality of the vacuum system (high-vacuum capability) and the precision of the temperature control for maximum uniformity.

- If your primary focus is rapid material testing and frequent sample changes: Prioritize a cold-wall design with a fast gas-cooling system to minimize cycle times.

- If your primary focus is sintering or synthesis at extreme temperatures (>1500°C): Prioritize a furnace with a corundum tube, appropriate high-temperature heating elements (like MoSi2 or graphite), and robust insulation.

Understanding these interconnected systems empowers you to control your material's processing environment with precision and intent.

Summary Table:

| Component | Key Features | Benefits |

|---|---|---|

| Furnace Chamber | Sealed quartz or corundum tube with stainless steel flanges | Creates controlled, non-oxidizing atmosphere for purity |

| Vacuum System | Vacuum pumps (e.g., mechanical, molecular) and valves | Prevents oxidation and unwanted reactions |

| Heating System | Elements like SiC, MoSi2, graphite; temperatures >1000°C | Enables uniform, high-temperature processing |

| Control System | PID temperature controllers with programmed ramps | Ensures accuracy and repeatability in experiments |

| Cooling System | Water-cooled jackets or gas circulation | Protects components and allows rapid cooling |

Ready to elevate your lab's capabilities with a custom vacuum tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet unique experimental requirements. Contact us today to discuss how we can enhance your material processing with precision and reliability!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis