A high-temperature muffle furnace combined with an air-cooling system is indispensable for accurately evaluating the thermal stability of Al–Ce–La–Ni–Fe alloys. This equipment provides the precise control necessary to perform long-term annealing treatments—such as holding at 400°C for 10 hours—which are required to simulate the extreme thermal environments these materials will encounter in service.

By maintaining a stable thermal environment and utilizing controlled air cooling, this process isolates the variables necessary to verify the anti-coarsening capabilities of key alloy phases. It serves as the primary method for linking microstructural evolution to long-term mechanical stability.

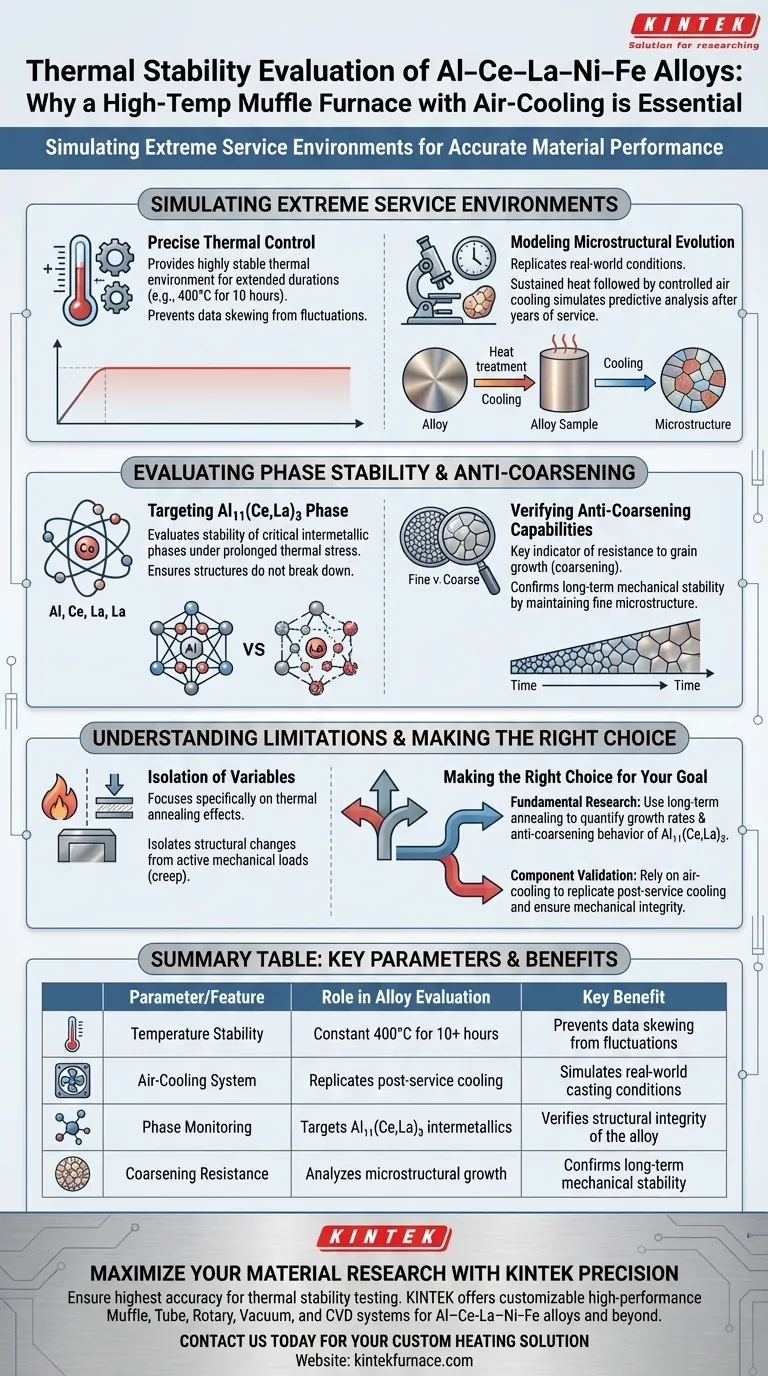

Simulating Extreme Service Environments

Precise Thermal Control

The primary function of the muffle furnace is to provide a highly stable thermal environment over extended durations.

Fluctuations in temperature can skew data regarding material degradation. This stability ensures that the annealing process, specifically at parameters like 400°C for 10 hours, is consistent and reproducible.

Modeling Microstructural Evolution

The goal of this thermal treatment is to replicate the conditions a casting faces during real-world operation.

By subjecting the alloy to sustained heat followed by air cooling, researchers can simulate the microstructural evolution of the material. This allows for a predictive analysis of how the alloy will behave after years of service in high-temperature applications.

Evaluating Phase Stability

Targeting the Al11(Ce,La)3 Phase

The evaluation focuses heavily on specific intermetallic phases within the alloy, particularly Al11(Ce,La)3.

These phases are critical to the alloy's performance. The furnace test determines if these structures remain stable or break down when exposed to prolonged thermal stress.

Verifying Anti-Coarsening Capabilities

A key indicator of stability is the alloy's resistance to "coarsening," where fine microstructures grow larger and lose effectiveness.

This equipment allows engineers to verify the anti-coarsening capabilities of the phases. Proving that the microstructure resists coarsening is essential for confirming the material's mechanical stability.

Understanding the Limitations

Isolation of Variables

It is important to recognize that this method focuses specifically on thermal annealing.

While it effectively simulates microstructural changes due to heat, it typically isolates these effects from active mechanical loads (creep) during the heating cycle. It verifies the stability of the material's structure, rather than its immediate response to physical stress while hot.

Making the Right Choice for Your Goal

To effectively utilize this equipment for your specific objectives:

- If your primary focus is fundamental research: Use the long-term annealing capability to quantify the specific growth rates and anti-coarsening behavior of the Al11(Ce,La)3 phase.

- If your primary focus is component validation: Rely on the air-cooling cycle to replicate post-service cooling rates to ensure the casting retains its mechanical integrity after thermal exposure.

Reliable performance data begins with the precise simulation of your material's worst-case thermal environment.

Summary Table:

| Parameter/Feature | Role in Alloy Evaluation | Key Benefit |

|---|---|---|

| Temperature Stability | Constant 400°C for 10+ hours | Prevents data skewing from fluctuations |

| Air-Cooling System | Replicates post-service cooling | Simulates real-world casting conditions |

| Phase Monitoring | Targets Al11(Ce,La)3 intermetallics | Verifies structural integrity of the alloy |

| Coarsening Resistance | Analyzes microstructural growth | Confirms long-term mechanical stability |

Maximize Your Material Research with KINTEK Precision

Ensure the highest level of accuracy for your thermal stability testing. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research parameters for Al–Ce–La–Ni–Fe alloys and beyond.

Our advanced lab high-temp furnaces provide the stable environments and controlled cooling necessary to verify anti-coarsening capabilities and microstructural evolution. Contact us today to find your custom heating solution.

Visual Guide

References

- Benjamin E. MacDonald, Diran Apelian. High-Pressure Die Casting of Al–Ce–La–Ni–Fe Alloys. DOI: 10.1007/s40962-023-01252-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does an industrial-grade muffle furnace contribute to the catalyst activation process? Maximize Catalyst Efficiency

- How is a muffle furnace utilized to determine the thermal stability of NaA zeolite? Expert Stress-Test Analysis

- What role do muffle furnaces play in sintering 3D-printed beta-TCP? Optimize Your Bioceramic Results

- What critical support does an industrial muffle furnace provide in mineral dielectric evolution? Real-Time Insights

- Why is working temperature the most crucial factor when choosing a muffle furnace? Ensure Your Process Success with the Right Heat

- How do muffle furnaces contribute to research and quality control? Unlock Precision and Purity in Material Analysis

- Why is a laboratory high-temperature muffle furnace used for BaTiO3? Achieve Optimal Tetragonal Crystalline Phases

- What is the difference between batch furnace and continuous furnace? Flexibility vs. High-Volume Efficiency