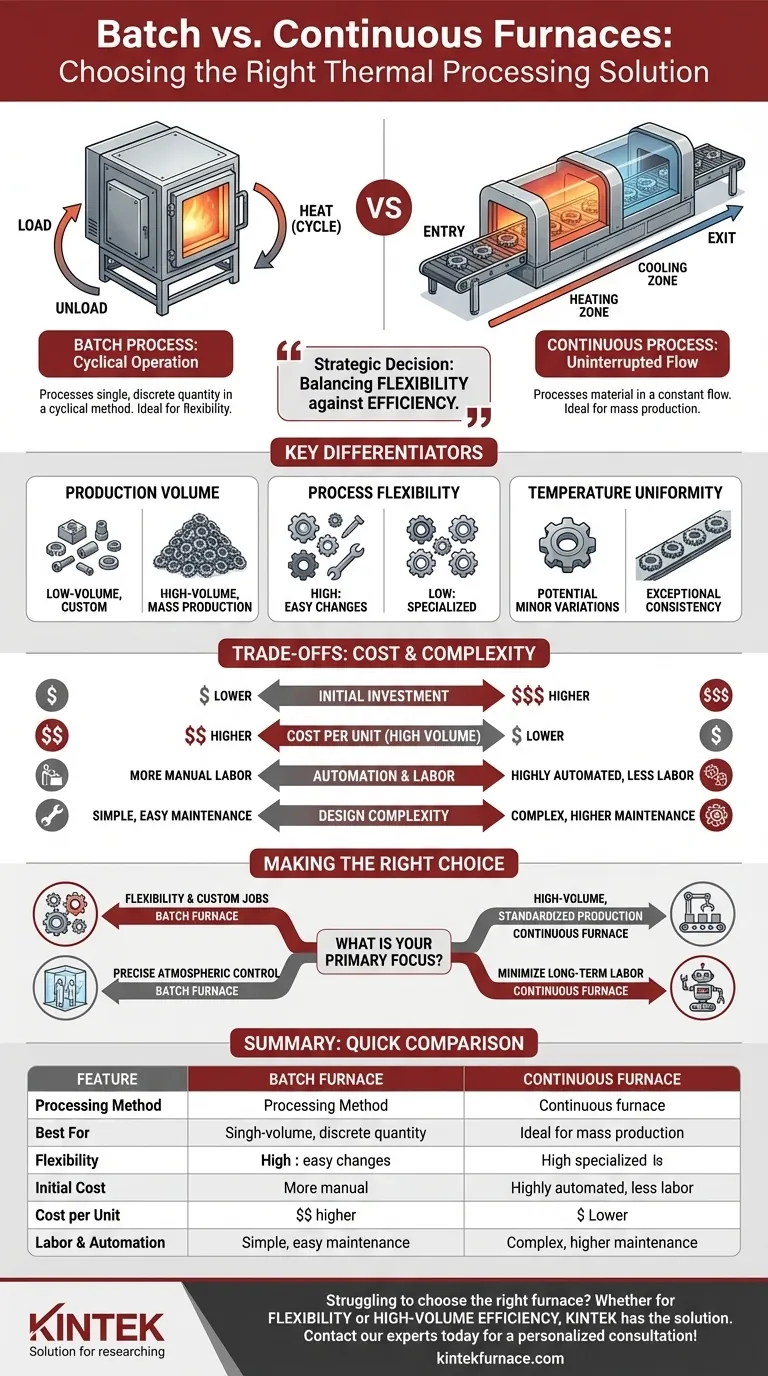

The fundamental difference between a batch furnace and a continuous furnace lies in their processing method. A batch furnace processes a single, discrete quantity of material at a time in a cyclical process of loading, heating, and unloading. In contrast, a continuous furnace processes material in an uninterrupted flow, with the workload constantly moving through the furnace from an entry point to an exit point.

The choice between them is a strategic decision balancing flexibility against efficiency. Batch furnaces provide the versatility to handle varied products and processes, while continuous furnaces deliver high efficiency and automation for mass production of a single, standardized product.

How They Work: A Fundamental Divide

Understanding the operational model of each furnace type is key to grasping their distinct advantages and applications. They represent two fundamentally different philosophies of thermal processing.

The Batch Process: Load, Heat, Unload

A batch furnace operates on a start-to-finish cycle for a specific "batch" or load. The material is placed inside, the furnace is sealed, and a specific heating (and sometimes cooling) profile is executed.

Once the cycle is complete, the furnace must be cooled before the finished product is removed. The entire process must then be repeated for the next batch. This makes them ideal for processing discrete quantities in a sealed, controlled environment.

The Continuous Process: A Constant Flow

A continuous furnace functions like an assembly line. Material is fed into one end, moves through various temperature zones on a conveyor or similar transport mechanism, and exits the other end fully processed.

These systems are designed for non-stop operation. Their capacity is determined not by chamber size, but by the rate at which material can be fed in and the speed it travels through the furnace. This allows for integrated heating and cooling sections within one seamless operation.

Key Differentiators: Volume vs. Versatility

The operational differences create distinct advantages depending on the production goal. The decision hinges on whether you need to produce a high volume of one thing or have the flexibility to produce many different things.

Production Volume and Throughput

Continuous furnaces are built for mass production. They are best suited for high-volume manufacturing where the components have the same size, composition, and required heat treatment cycle.

Batch furnaces excel at lower-volume or custom jobs. Their nature makes them perfect for industries that require frequent changes in production parameters or produce a wide variety of parts.

Process Flexibility

Batch furnaces offer maximum flexibility. Since each run is independent, you can easily change the temperature, cycle time, or atmospheric conditions for every new batch. This is critical for research, development, and custom manufacturing.

Continuous furnaces are highly specialized. They are typically configured for a single, optimized process. Changing the setup is a complex and time-consuming task, making them unsuitable for varied production needs.

Temperature Uniformity and Control

Continuous furnaces provide exceptional consistency. As each individual item moves through the furnace, it is exposed to the exact same temperature profile, ensuring high uniformity across the entire production run.

Batch furnaces heat an entire chamber at once. While modern designs offer excellent temperature control, there can be minor variations between parts located at the center of the load versus those on the perimeter.

Understanding the Trade-offs: Cost and Complexity

Beyond production philosophy, the financial and operational implications of each furnace type are significant.

Initial Investment vs. Operational Cost

A continuous furnace represents a major capital investment due to its complexity and automation. However, for high-volume runs, its efficiency and reduced labor needs result in a lower cost per unit produced.

A batch furnace is significantly less expensive to acquire and install. Its simpler design translates to a lower barrier to entry, though its operational cost per unit can be higher if used for mass production due to labor and energy cycling.

Automation and Labor Requirements

Continuous furnaces are highly automated, requiring minimal manual intervention once running. This drastically reduces ongoing labor costs.

Batch furnaces typically require more manual labor for loading and unloading between each cycle. While automation is possible, the process is inherently less hands-off than a continuous system.

Design Complexity and Maintenance

With fewer moving parts, batch furnaces are simpler in design, which generally makes them easier to operate and maintain.

Continuous furnaces are complex systems with conveyors and advanced automation. This complexity can lead to higher maintenance requirements to ensure reliable, non-stop operation.

Making the Right Choice for Your Application

The ideal furnace is not the most advanced one, but the one that aligns with your specific production strategy.

- If your primary focus is flexibility and custom jobs: A batch furnace is the superior choice, allowing you to adapt to different products and processes with ease.

- If your primary focus is high-volume, standardized production: A continuous furnace offers unmatched efficiency and lower per-unit costs at scale.

- If you operate in a cleanroom or require precise atmospheric control for varied batches: A sealed batch furnace provides the necessary process integrity and versatility.

- If your goal is to minimize long-term labor costs for a single product line: The automation of a continuous furnace will deliver the best return on investment.

Ultimately, your decision should be driven by an honest assessment of your product mix, production volume, and long-term business goals.

Summary Table:

| Feature | Batch Furnace | Continuous Furnace |

|---|---|---|

| Processing Method | Cyclical: Load, Heat, Unload | Uninterrupted flow through zones |

| Best For | Low-volume, custom jobs, R&D | High-volume, mass production |

| Flexibility | High (easy process changes) | Low (specialized for one process) |

| Initial Cost | Lower | Higher (major capital investment) |

| Cost per Unit (High Volume) | Higher | Lower |

| Labor & Automation | More manual labor | Highly automated, less labor |

Struggling to choose the right furnace for your production line?

Whether your priority is the flexibility of a batch furnace for varied R&D and custom jobs, or the high-volume efficiency of a continuous furnace for mass production, KINTEK has the solution. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories and production facilities with advanced high-temperature furnace solutions.

Our extensive product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique thermal processing requirements.

Let our experts help you optimize your process. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput