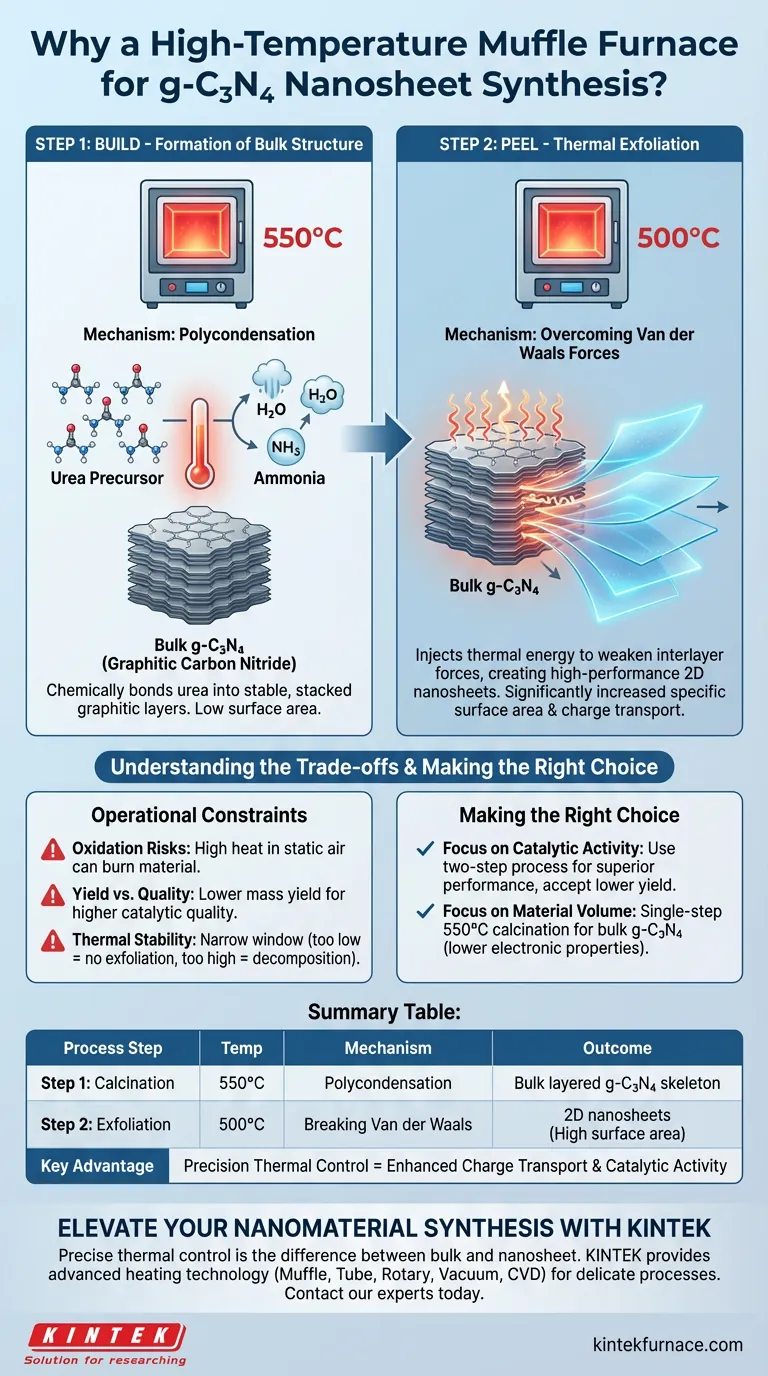

The primary role of a high-temperature muffle furnace in this context is to facilitate a "build-and-peel" mechanism that transforms raw precursors into high-performance 2D nanosheets.

Specifically, the furnace creates a stable thermal environment for two distinct phases: first, chemically bonding urea into a bulk layered structure at 550°C, and second, physically exfoliating those layers at 500°C to dramatically increase surface area and charge transport efficiency.

The Core Takeaway The two-step thermal treatment utilizes the muffle furnace not just for synthesis, but for structural modification. By precisely controlling thermal energy, you first drive the chemical reaction to create a graphitic skeleton, then use a secondary heating phase to overcome van der Waals forces, thinning the material into highly active nanosheets.

Step 1: Formation of the Bulk Structure

The first phase of the process is strictly chemical. It relies on the muffle furnace to provide a high-temperature environment (typically 550°C) to facilitate polycondensation.

Creating the Skeleton

At this stage, the furnace heats the precursor (commonly urea) to induce a chemical reaction. The thermal energy drives the precursor molecules to link together, releasing ammonia and other gases.

The Resulting Structure

This process builds a "bulk" graphitic carbon nitride (g-C3N4) structure. This material is composed of stacked layers, similar to graphite. While stable, this bulk form has a relatively low specific surface area, which limits its catalytic performance.

Step 2: Thermal Exfoliation

The second step is the defining reason for the "two-step" methodology. The material is subjected to a secondary heat treatment, often at a slightly lower temperature (500°C).

Overcoming Van der Waals Forces

The layers in the bulk g-C3N4 are held together by weak van der Waals forces. The second thermal treatment injects enough thermal energy to weaken and overcome these forces without decomposing the individual layers.

The Thinning Effect

As these interlayer forces break, the bulk structure "peels" or exfoliates. This transforms the thick, stacked material into ultra-thin 2D nanosheets.

Performance Enhancements

This structural change is critical for functionality. The thinning process significantly increases the specific surface area, providing more active sites for reactions. Additionally, the shorter diffusion distance in nanosheets improves the transport efficiency of photogenerated charges.

Understanding the Trade-offs

While the high-temperature muffle furnace is effective for this synthesis, it is important to understand the operational constraints and potential pitfalls.

Oxidation Risks

Muffle furnaces typically operate with static air. In a two-step process, prolonged exposure to high heat in an oxygen-rich environment can lead to excessive oxidation or "burning off" of the material if the temperature is not strictly controlled.

Yield vs. Quality

Thermal exfoliation is a subtractive process. While it creates high-quality nanosheets, it often results in a lower mass yield compared to the bulk starting material. You are trading material quantity for significantly higher catalytic quality.

Thermal Stability

The window for exfoliation is narrow. If the secondary temperature is too low (e.g., <400°C), exfoliation may not occur. If it is too high (approaching the decomposition point), the graphitic framework itself may collapse.

Making the Right Choice for Your Goal

The decision to utilize a two-step thermal treatment in a muffle furnace depends on the specific requirements of your final application.

- If your primary focus is maximizing catalytic activity: Use the two-step process to generate nanosheets, accepting a lower yield for the sake of superior charge transport and surface area.

- If your primary focus is material volume: A single-step calcination at 550°C is sufficient to produce bulk g-C3N4, though it will lack the enhanced electronic properties of the nanosheets.

Ultimately, the muffle furnace acts as a precision tool that converts thermal energy into structural refinement, turning a standard chemical compound into a high-performance functional nanomaterial.

Summary Table:

| Process Step | Temperature | Primary Mechanism | Structural Outcome |

|---|---|---|---|

| Step 1: Calcination | 550°C | Polycondensation | Formation of bulk layered g-C3N4 skeleton |

| Step 2: Exfoliation | 500°C | Breaking Van der Waals forces | Thinning into 2D nanosheets with high surface area |

| Key Advantage | - | Precision Thermal Control | Enhanced charge transport and catalytic activity |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise thermal control is the difference between a bulk material and a high-performance 2D nanosheet. KINTEK provides the advanced heating technology required to master delicate processes like thermal exfoliation and polycondensation.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific research or production needs. Whether you are optimizing g-C3N4 yields or developing next-generation catalysts, our high-temperature furnaces deliver the uniformity and stability your materials demand.

Ready to refine your results? Contact our technical experts today to find the perfect furnace solution for your lab.

Visual Guide

References

- Qiuyu Chen, Rongzhi Chen. Facilitated Unidirectional Electron Transmission by Ru Nano Particulars Distribution on MXene Mo2C@g-C3N4 Heterostructures for Enhanced Photocatalytic H2 Evolution. DOI: 10.3390/molecules29071684

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What applications does a muffle furnace have in coal quality analysis? Essential for Precise Coal Testing

- How does a high-temperature muffle furnace contribute to the formation of the ZrO2-ZnO heterojunction?

- What types of box furnaces are available based on power source? Choose Electric or Gas for Your Needs

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- How should temperature be managed when using a muffle furnace? Master Precise Control for Safety and Accuracy

- Why are muffle furnaces not suitable for low-temperature applications? Discover the High-Temperature Design Limits

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- What is the role of high-temperature calcination in a muffle furnace? Create Precision Bioactive Glass