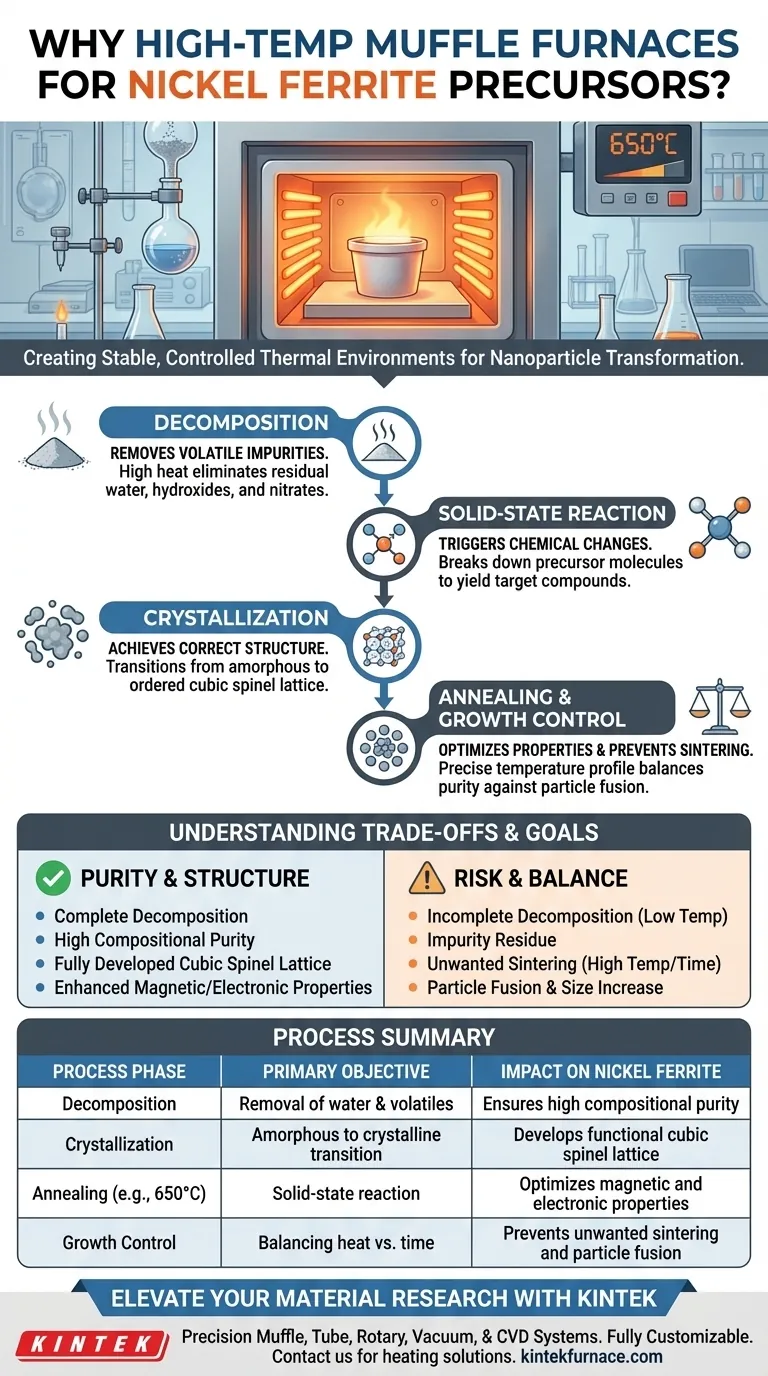

A high-temperature muffle furnace is required to create a stable, controlled thermal environment that drives the necessary chemical and physical changes in nanoparticle precursors. Specifically for nickel ferrite, this equipment creates the conditions—often around 650°C—needed to decompose hydroxide precursors and initiate solid-state reactions.

The furnace serves a dual purpose: it purifies the material by eliminating residual water and volatile impurities, and it provides the energy required to organize the atomic structure into the high-quality cubic spinel lattice characteristic of functional nickel ferrite.

The Mechanics of Thermal Decomposition

Removing Volatile Impurities

Freshly deposited precursors, particularly hydroxides or nitrates, invariably contain unwanted residuals. The high heat of the muffle furnace drives off residual water and volatile compounds that would otherwise contaminate the final product.

Triggering Solid-State Reactions

The conversion from a precursor to a final ceramic material is not merely about drying; it requires a chemical change. The furnace provides the thermal energy necessary to break down the precursor molecules and facilitate the reaction that yields the target compound.

Achieving the Correct Crystal Structure

Transitioning from Amorphous to Crystalline

Precursors often start in an amorphous or semi-crystalline state with no long-range atomic order. The annealing process supplies the energy required for nucleation and growth, allowing atoms to rearrange themselves into a highly ordered lattice.

Forming the Cubic Spinel Structure

For nickel ferrite (NiFe2O4), the target is a specific standard cubic spinel structure. The muffle furnace ensures the material reaches the precise temperature (e.g., 650°C) required to fully develop this crystal phase, which directly dictates the material's magnetic and electronic properties.

Understanding the Trade-offs

Temperature Precision

While high heat is necessary, the specific temperature profile is critical. If the temperature is too low, decomposition remains incomplete, leaving impurities that degrade performance.

Risk of Sintering

Conversely, excessive heat or prolonged exposure can cause the nanoparticles to sinter, or fuse together. This increases particle size and destroys the high surface area that makes nanoparticles valuable in the first place.

Making the Right Choice for Your Goal

To optimize your post-treatment process, you must balance purity against particle size.

- If your primary focus is compositional purity: Prioritize temperatures high enough (e.g., 650°C) to ensure the complete removal of hydroxides, nitrates, and residual water.

- If your primary focus is electrochemical performance: Ensure the heat treatment is long enough to fully develop the crystalline spinel structure, as amorphous phases often yield poor performance.

The muffle furnace is not just a heater; it is the environment that defines the final structural integrity of your material.

Summary Table:

| Process Phase | Primary Objective | Impact on Nickel Ferrite |

|---|---|---|

| Decomposition | Removal of water & volatiles | Ensures high compositional purity |

| Crystallization | Amorphous to crystalline transition | Develops the functional cubic spinel lattice |

| Annealing | Solid-state reaction (e.g., 650°C) | Optimizes magnetic and electronic properties |

| Growth Control | Balancing heat vs. time | Prevents unwanted sintering and particle fusion |

Elevate Your Material Research with KINTEK

Precision is non-negotiable when synthesizing high-performance nanoparticles. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed to give you total control over your thermal profiles. Backed by expert R&D and manufacturing, our lab high-temp furnaces are fully customizable to meet the rigorous demands of your specific nickel ferrite or ceramic research.

Ready to achieve superior crystalline purity? Contact our technical experts today to find the perfect heating solution for your laboratory.

Visual Guide

References

- D. I. Nemkova, Anton Krolikov. Effect of Amino Acids on the Synthesis of NiFe2O4/Au Hybrid Nanoparticles. DOI: 10.3390/cryst15010072

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a vacuum muffle furnace used to perform proximate analysis? Precise Biomass Evaluation & Reactivity Analysis

- What role does an industrial microwave muffle furnace play in the sintering process of porous mullite ceramic skeletons?

- Why is the calcination process in a muffle furnace necessary for preparing bimetallic oxide CuCo2O4?

- What is the function of a high-temperature box furnace in Ge-S-Cd synthesis? Master 900°C Melting Kinetics

- What are the different types of muffle furnaces? Choose the Right Furnace for Your Lab Needs

- What function does a muffle furnace perform in converting precursors into CSO? Key Insights for Material Synthesis

- What core function does a muffle furnace serve in superconducting material synthesis? Master Solid-State Reactions

- How are box type electric furnaces used in the ceramics field? Unlock Precision in Firing and Sintering