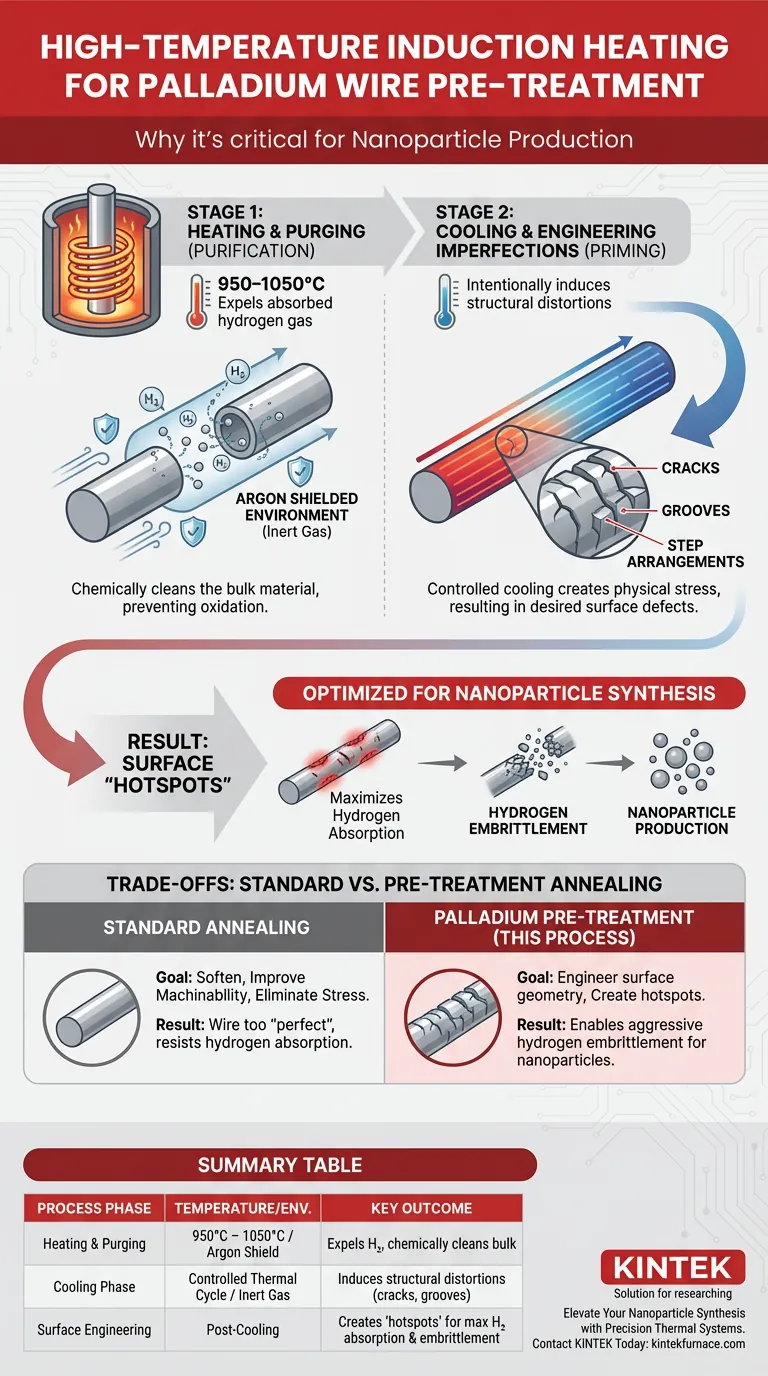

A high-temperature induction heating furnace is the critical driver for preparing palladium wire for nanoparticle production. Specifically, it heats the wire to between 950 and 1050 degrees Celsius in an argon-shielded environment to purge the metal of absorbed hydrogen gas. Furthermore, the specific thermal cycle allows for a cooling phase that intentionally induces structural distortions—such as cracks and grooves—which are essential for subsequent processing.

Core Takeaway: This process is not merely about softening the metal; it is a strategic method to "prime" the material. By expelling existing gas and then structurally compromising the surface during cooling, the treatment creates "hotspots" that maximize hydrogen absorption and facilitate the embrittlement required to produce nanoparticles.

The Mechanics of the Thermal Cycle

To understand why this furnace is required, we must look beyond simple heating. The process serves two distinct functions: purification during the heating phase and restructuring during the cooling phase.

Purging the Palladium Bulk

The primary objective of raising the temperature to the 950–1050°C range is purification. Palladium has a high affinity for hydrogen, absorbing it easily.

Before further processing can occur, the induction furnace drives this absorbed hydrogen gas out of the palladium bulk. This "reset" ensures that the material is chemically clean and ready for the next stage of treatment.

The Importance of the Argon Shield

This heating process occurs within an argon-shielded environment.

Argon is an inert gas, meaning it prevents oxidation and other chemical reactions that would degrade the quality of the wire at such high temperatures. This ensures the purification process does not inadvertently introduce new contaminants.

Engineering Surface Imperfections

While standard annealing typically aims to reduce defects, this specific pre-treatment utilizes the furnace to intentionally create them.

Inducing Structural Distortions

The cooling phase that follows the high-temperature heating is just as critical as the heating itself. As the wire cools, the metal undergoes significant physical changes.

This thermal stress induces structural distortions on the wire's surface. These manifest as step arrangements, deep grooves, or grain boundary cracks.

Creating Absorption "Hotspots"

These surface imperfections are not errors; they are the goal.

The distortions serve as hotspots for hydrogen absorption. By increasing the surface area and creating entry points, the furnace effectively engineers the wire to absorb hydrogen more aggressively in future steps.

Enabling Nanoparticle Production

The ultimate reason for this furnace treatment is to facilitate the production of nanoparticles.

The process relies on hydrogen embrittlement—weakening the metal so it can be broken down. The cracks and grooves created during the cooling phase enhance this embrittlement effect, making the subsequent reduction of the wire into nanoparticles efficient and effective.

Understanding the Trade-offs

It is vital to distinguish this specific application from general annealing practices to avoid process errors.

Intentional Defect vs. Standard Annealing

In general metallurgy, annealing is used to soften materials, improve machinability, or eliminate thermomechanical stresses.

However, in this specific palladium pre-treatment, the goal is not simply to restore the properties of the pure metal or maximize smoothness. If you utilize a standard annealing cycle designed only for stress relief, you may fail to generate the necessary surface cracks (hotspots).

The Risk of Improper Cooling

If the cooling phase is not managed correctly to induce distortions, the wire may become too "perfect."

A wire without step arrangements or grooves will resist the hydrogen absorption required later. This effectively renders the material unsuitable for the embrittlement process needed to generate nanoparticles.

Making the Right Choice for Your Goal

The use of a high-temperature induction furnace is specific to the outcome you wish to achieve with the palladium wire.

- If your primary focus is Nanoparticle Production: You must prioritize the cooling phase to ensure structural distortions (grooves and cracks) are formed to act as hydrogen absorption hotspots.

- If your primary focus is General Machinability: You would likely alter the cooling profile to focus on softening the material and eliminating stress, rather than inducing surface defects.

Ultimately, the induction furnace is required not just to heat the wire, but to engineer its surface geometry for maximum hydrogen reactivity.

Summary Table:

| Process Phase | Temperature Range | Environment | Key Outcome |

|---|---|---|---|

| Heating & Purging | 950°C – 1050°C | Argon Shielded | Expels absorbed hydrogen; chemically cleans the palladium bulk |

| Cooling Phase | Controlled Thermal Cycle | Inert Gas | Induces structural distortions (cracks, grooves, step arrangements) |

| Surface Engineering | Post-Cooling | Ambient/Controlled | Creates 'hotspots' for max hydrogen absorption & embrittlement |

Elevate Your Nanoparticle Synthesis with Precision Thermal Systems

Unlock the full potential of your material pre-treatment with KINTEK’s advanced high-temperature induction heating solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of palladium processing and beyond.

Whether you require specific thermal cycles to induce structural distortions or precise atmosphere control to ensure purity, our lab high-temp furnaces are fully customizable to your unique research and production needs.

Ready to optimize your hydrogen absorption efficiency?

Contact KINTEK Today to Consult with Our Experts

Visual Guide

References

- Christian M. Schott, Elena L. Gubanova. Top‐down Surfactant‐Free Synthesis of Supported Palladium‐Nanostructured Catalysts. DOI: 10.1002/smsc.202300241

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the benefits of reduced furnace lining burn loss in IGBT induction melting furnaces? Lower Total Casting Costs

- How does high thermal efficiency benefit induction furnaces? Unlock Major Cost Savings & Quality

- What are some common operational issues with induction-heated vacuum furnaces and how can they be addressed? Boost Reliability and Efficiency

- What are the technical advantages of using a vacuum melting furnace? Master Superior Quartz Glass Preparation

- What makes induction vacuum melting possible? Unlock Ultra-Pure Metal Production

- What makes induction furnaces energy efficient? Direct Internal Heating Saves 30-80% in Energy

- What are the advantages of using an induction-heated vacuum furnace? Achieve Purity and Precision in Material Processing

- What is a vacuum induction melting (VIM) furnace and why is it important? Achieve Unmatched Metal Purity for Critical Applications