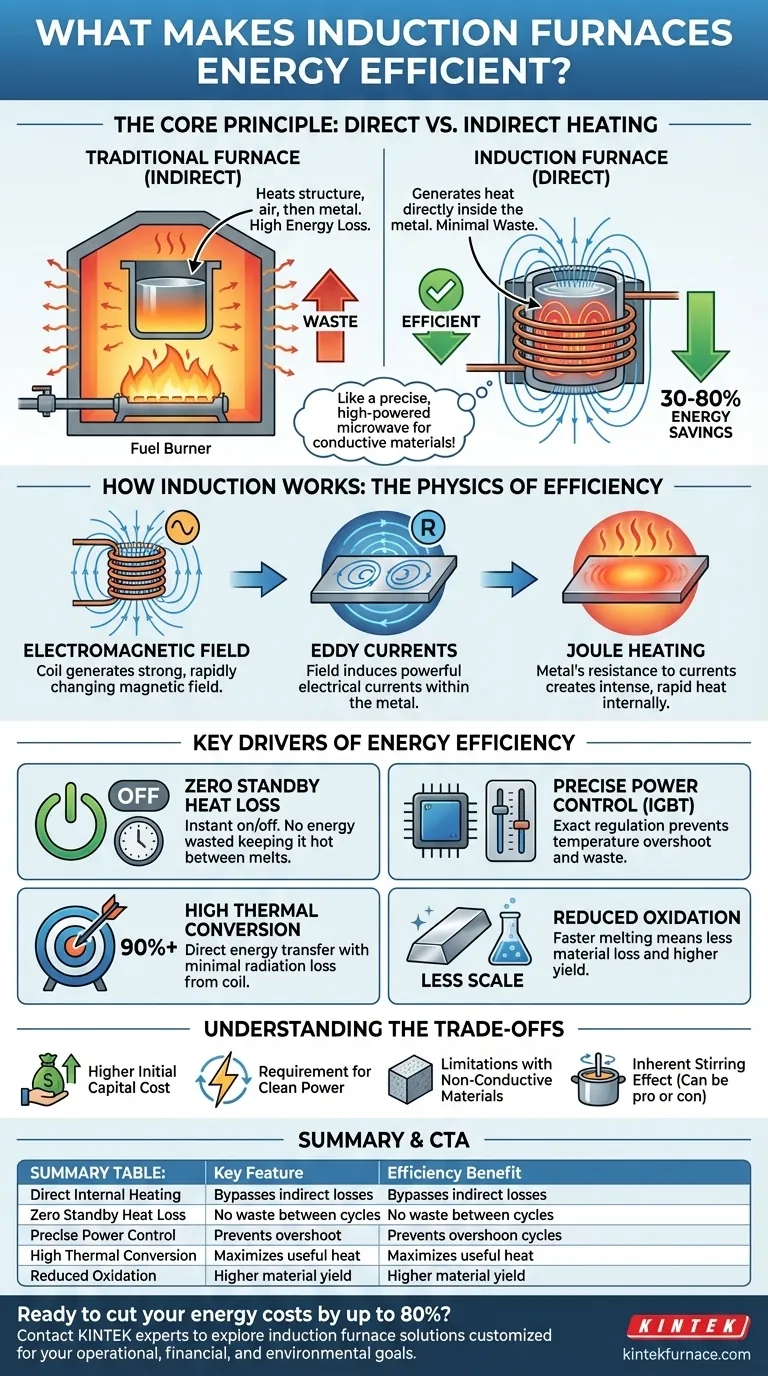

Fundamentally, an induction furnace’s energy efficiency comes from its unique method of heating. Unlike traditional furnaces that burn fuel to heat a chamber, an induction furnace uses a powerful, controlled electromagnetic field to generate heat directly inside the metal itself. This process is incredibly direct, eliminating the massive energy losses associated with heating the furnace structure, the surrounding air, and transferring that heat indirectly to the target material.

Traditional furnaces waste energy by heating everything around the metal. An induction furnace functions like a precise, high-powered microwave for conductive materials, transferring energy directly into the charge with minimal waste, resulting in energy savings of 30-80%.

The Core Principle: Direct Internal Heating

The efficiency of induction technology is rooted in its physics. It bypasses the slow and wasteful steps of conventional heating by making the material its own heat source.

How Induction Works: An Electromagnetic Field

An induction furnace uses a water-cooled copper coil through which a powerful alternating electrical current flows. This current generates a strong, rapidly changing magnetic field around and within the crucible containing the metal charge.

Resistance Creates Heat (Joule Heating)

This magnetic field induces powerful electrical currents, known as eddy currents, to flow within the conductive metal. The metal’s natural electrical resistance opposes the flow of these eddy currents, generating intense and rapid heat directly inside the material.

Bypassing Indirect Heat Transfer

Conventional furnaces operate by combustion or resistance elements, which first heat the furnace walls and atmosphere. That heat must then be transferred to the metal via radiation and convection. Each step in this indirect process loses significant energy to the environment. Induction skips these steps entirely.

Key Drivers of Energy Efficiency

Several distinct features contribute to the induction furnace's lower power consumption and operational costs.

Zero Standby Heat Loss

A conventional furnace must be held at a high temperature between uses, consuming a constant stream of energy just to stay ready. An induction furnace has zero standby heat loss because the heating is instantaneous. It can be powered off completely between melts and brought to full power in minutes, saving enormous amounts of energy during idle periods.

Precise Electronic Power Control

Modern induction furnaces use solid-state technology, like IGBT (Insulated-Gate Bipolar Transistor) systems, for power control. These electronics allow for instant and precise regulation of frequency and power. This ensures only the exact amount of energy required for the melt cycle is used, preventing temperature overshoot and waste.

High Thermal Conversion Rate

Because the heat is generated inside the target material, the efficiency of converting electrical energy into useful thermal energy is extremely high. Very little energy radiates away from the coil itself; most of it is coupled directly into the metal charge.

Reduced Oxidation and Material Loss

The fast melting time significantly reduces the opportunity for the molten metal to react with oxygen in the atmosphere. This results in less oxidation (scale) and therefore higher material yield, which is a direct financial and resource saving.

Understanding the Trade-offs

While highly efficient, induction technology is not a universal solution. Acknowledging its limitations is critical for a sound technical decision.

Higher Initial Capital Cost

Induction furnaces, with their advanced power supplies and copper coils, typically have a higher upfront purchase price compared to simpler fuel-fired furnaces. This cost must be weighed against the long-term savings in energy, materials, and maintenance.

Requirement for Clean Power

The high-frequency power electronics that drive an induction furnace are sensitive to the quality of the electrical supply. They require a stable, reliable power grid and may need additional equipment to filter out electrical noise or harmonics.

Limitations with Non-Conductive Materials

Induction heating only works on materials that are electrically conductive. It is an ideal technology for melting iron, steel, copper, and aluminum, but it cannot be used to directly heat insulating materials like ceramics or certain types of contaminants in a scrap charge.

The Inherent Stirring Effect

The electromagnetic field creates a natural, often vigorous stirring action within the molten metal. While this is a significant advantage for creating a uniform temperature and homogenous alloy, it can be undesirable for certain specialized applications where a quiescent melt is required.

Making the Right Choice for Your Operation

Choosing the right furnace technology depends entirely on your primary operational goals.

- If your primary focus is minimizing operational costs: The induction furnace's high energy efficiency, lack of fuel consumption, and higher material yield make it the superior choice for long-term cost reduction.

- If your primary focus is production speed and flexibility: Induction's rapid heating and instant on/off capability provide unmatched agility for operations that require fast melts or frequent starts and stops.

- If your primary focus is environmental compliance and workplace safety: The fuel-free, emission-free operation of an induction furnace creates a cleaner, cooler, and safer work environment while eliminating CO2 and other combustion byproducts.

By understanding the core principle of direct internal heating, you can confidently determine how induction technology aligns with your financial, operational, and environmental objectives.

Summary Table:

| Key Feature | Efficiency Benefit |

|---|---|

| Direct Internal Heating | Generates heat directly inside the metal, bypassing energy losses from indirect heating. |

| Zero Standby Heat Loss | No energy wasted between cycles; furnace can be powered off completely. |

| Precise Power Control (IGBT) | Electronic regulation prevents temperature overshoot and energy waste. |

| High Thermal Conversion | Most electrical energy is converted directly into useful heat within the charge. |

| Reduced Oxidation | Faster melting times lead to less material loss and higher yield. |

Ready to cut your energy costs by up to 80%? At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced, high-efficiency induction furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique operational and financial goals.

Contact our experts today to explore how our induction technology can enhance your productivity, reduce operational expenses, and support your environmental objectives.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification