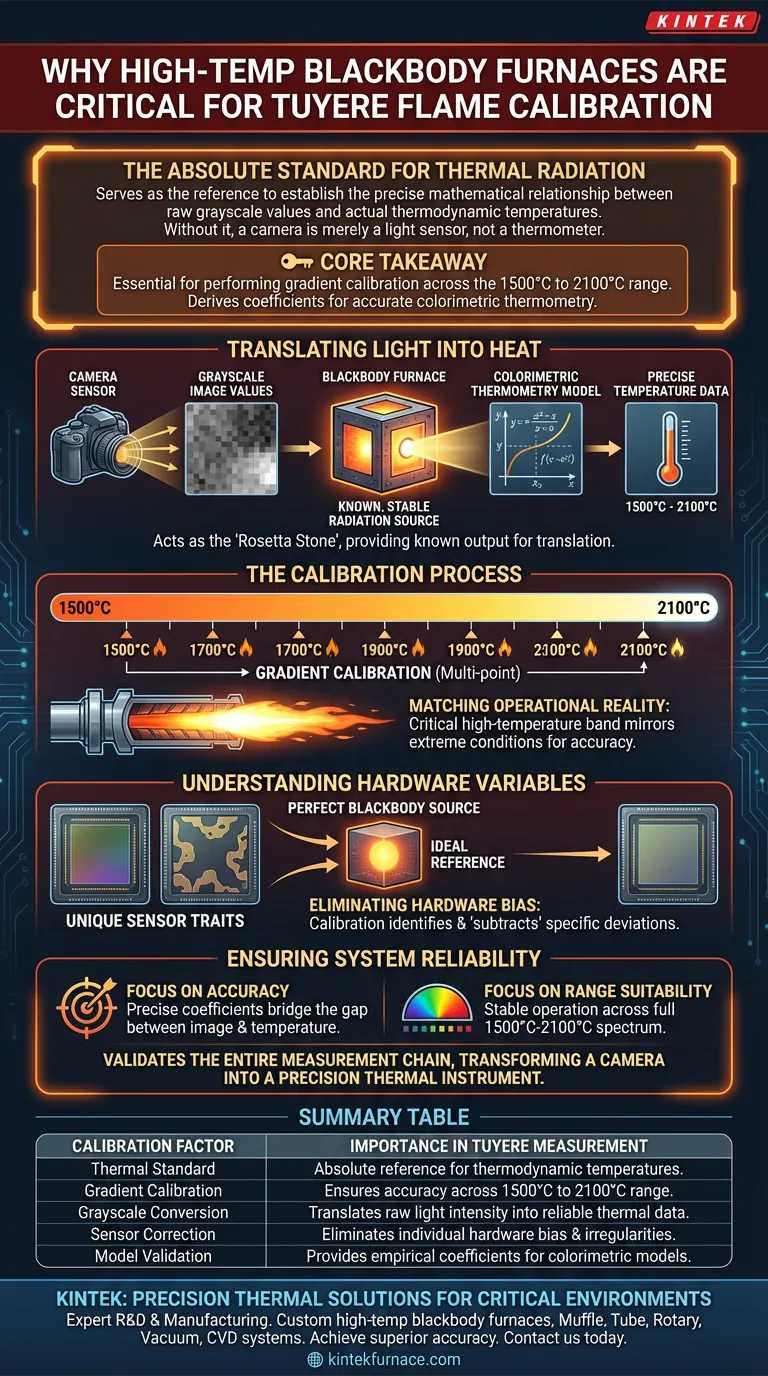

A high-temperature blackbody furnace is indispensable because it serves as the absolute standard for thermal radiation. It is required to establish the precise mathematical relationship between the raw grayscale values captured by your imaging equipment and the actual thermodynamic temperatures of the flame. Without this reference, a camera is merely a light sensor, not a thermometer.

Core Takeaway A blackbody furnace provides a known, stable radiation source essential for performing gradient calibration across the 1500°C to 2100°C range. This process derives the specific calibration coefficients needed to correct for camera sensor irregularities, ensuring the colorimetric thermometry model yields accurate data in the field.

The Gap Between Imaging and Measurement

Translating Light into Heat

A camera sensor does not inherently measure temperature; it captures light intensity, resulting in grayscale image values. To turn this visual data into thermal data, you need a translation layer. The blackbody furnace acts as the "Rosetta Stone" for this translation, providing a known temperature output that corresponds to a specific light intensity.

The Role of Colorimetric Models

The system uses a colorimetric thermometry model to calculate temperature. This mathematical model relies on specific coefficients to function correctly. These coefficients cannot be guessed; they must be empirically derived by observing a standard source—the blackbody furnace—at various known temperatures.

The Calibration Process

Gradient Calibration

Calibration is not a one-point check. It requires gradient calibration, which involves testing at multiple set points across the specific operating range of the tuyere.

Matching Operational Reality

The furnace allows for calibration specifically within the 1500°C to 2100°C range. Calibrating within this high-temperature band is critical because it mirrors the actual extreme conditions of a blast furnace tuyere, ensuring linearity and accuracy where it matters most.

Understanding Hardware Variables

Correcting Sensor Unique Traits

No two camera sensors are identical. Every device has unique photosensitive characteristics that can introduce errors into the measurement.

Eliminating Hardware Bias

By calibrating against a perfect blackbody source, you can identify exactly how a specific camera's sensor deviates from the ideal. The resulting calibration coefficients effectively "subtract" these hardware-specific errors from the final calculation.

Ensuring System Reliability

If your primary focus is Accuracy:

Prioritize generating precise calibration coefficients to bridge the gap between image grayscale and thermodynamic temperature.

If your primary focus is Range Suitability:

Ensure the blackbody furnace is capable of stable operation across the full 1500°C to 2100°C spectrum to match the tuyere environment.

Ultimately, the blackbody furnace validates the entire measurement chain, transforming a standard camera into a precision thermal instrument.

Summary Table:

| Calibration Factor | Importance in Tuyere Measurement |

|---|---|

| Thermal Standard | Serves as the absolute reference for thermodynamic temperatures. |

| Gradient Calibration | Ensures accuracy across the specific 1500°C to 2100°C range. |

| Grayscale Conversion | Translates raw image light intensity into reliable thermal data. |

| Sensor Correction | Eliminates individual hardware bias and photosensitive irregularities. |

| Model Validation | Provides empirical coefficients for colorimetric thermometry models. |

Precision Thermal Solutions for Critical Environments

Don't let measurement inaccuracies compromise your blast furnace operations. KINTEK provides the industry-leading high-temperature calibration solutions needed to transform raw data into actionable intelligence.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature blackbody furnaces customizable for your unique laboratory and industrial needs.

Ready to achieve superior accuracy? Contact KINTEK today to consult with our experts on the perfect high-temperature furnace solution for your application.

Visual Guide

References

- Haoyu Cai, Dongdong Zhou. Study of Tuyere Combustion Flame Temperature in Vanadium and Titanium Blast Furnaces by Machine Vision and Colorimetric Thermometry. DOI: 10.3390/met14050499

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What materials are used in the construction of the box furnace's structure? Durable Solutions for High-Temperature Applications

- What specialized processes utilize box furnaces? Discover Versatile Heat Treatment Solutions

- What precautions should be taken when using a muffle furnace for the first time or after a long shutdown? Ensure Safe and Long-Lasting Operation

- What role does a laboratory high-temperature muffle furnace play in the treatment of highly contaminated waste glass?

- What role does a muffle furnace play in calcination and sintering? Essential for High-Temperature Material Processing

- How does muffle furnace temperature precision affect thermoelectric alloys? Ensure Homogeneity in Every Ingot

- What are the critical functions of a muffle furnace in perovskite synthesis? Master High-Purity Precursor Production

- What safety feature is included in muffle furnaces to protect operators? Essential Safeguards for Lab Safety