Fundamentally, a muffle furnace acts as a high-temperature, precisely-controlled oven that is essential for both calcination and sintering. It provides the intense, uniform thermal energy required to transform raw materials into stable, durable products like ceramics and composites by heating them without any direct contact from flames or combustion gases.

The critical role of a muffle furnace is not just to provide high temperatures, but to do so within an isolated chamber. This separation protects the material from contamination by fuel or combustion byproducts, ensuring the purity and structural integrity required for successful calcination and sintering.

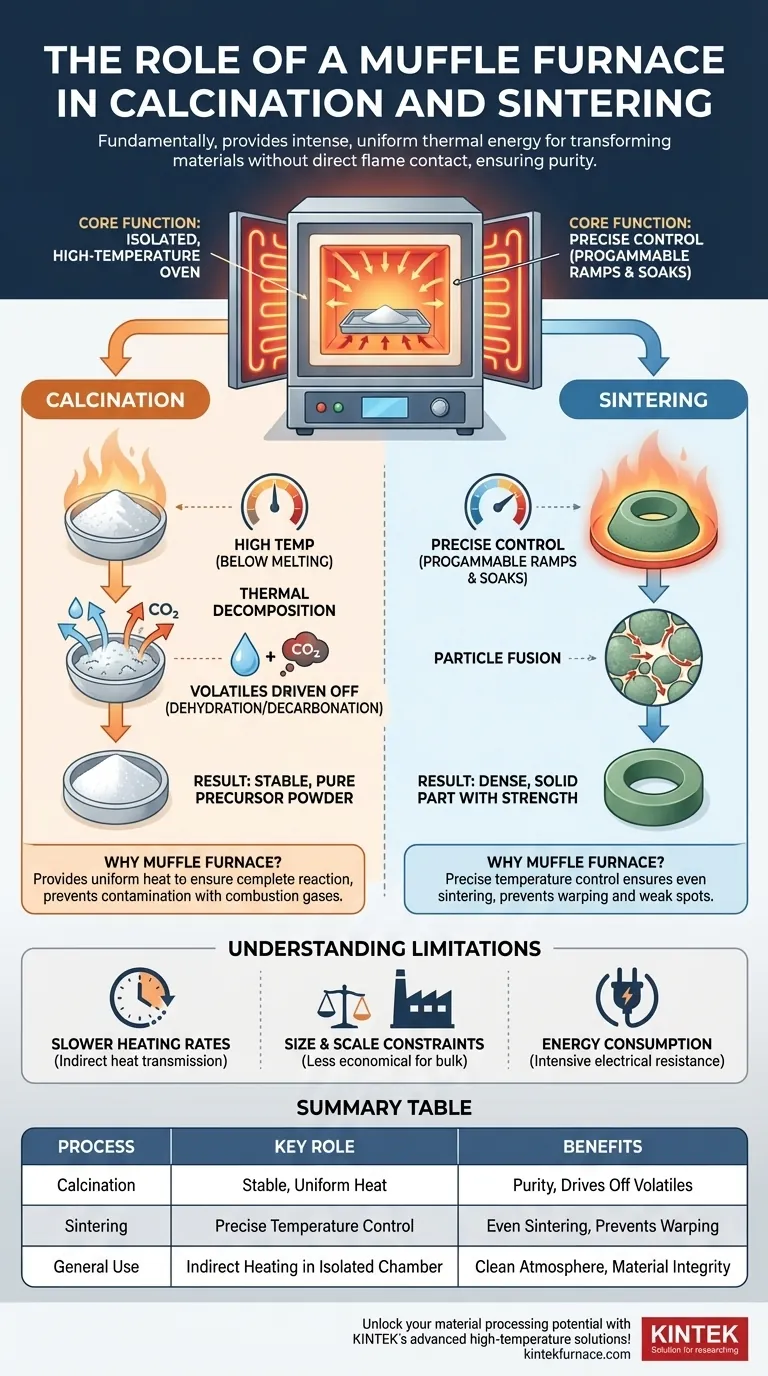

The Muffle Furnace: An Engine of Transformation

A muffle furnace is distinguished by its core design feature: the "muffle." This is an inner chamber, typically made of high-alumina refractory ceramic, that contains the material being heated.

The Principle of Indirect Heat

Heating elements are positioned outside this muffle, radiating thermal energy through the chamber walls to the sample.

This indirect heating is the furnace's defining characteristic. It ensures the material is heated uniformly and in a chemically clean environment, free from any contaminants that a direct flame would introduce.

Achieving Atmospheric Control

Because the muffle is a sealed chamber, the atmosphere inside can be tightly controlled. While many processes occur in ambient air, the chamber can also be purged and filled with an inert gas like argon or nitrogen to prevent oxidation of sensitive materials.

The Furnace's Role in Calcination

Calcination is often the first step in preparing a material for its final form. It is a process of thermal decomposition.

What is Calcination?

Calcination involves heating a solid material to a high temperature, but below its melting point, to induce a chemical change. This is typically done to drive off volatile substances like water (dehydration) or carbon dioxide (decarbonation).

Think of it as a high-temperature purification or preparation step. It creates a more stable, predictable base material for the next stage of processing.

Why the Muffle Furnace is Ideal

The muffle furnace provides the stable, uniform heat needed to ensure the calcination reaction completes throughout the entire sample. Its clean environment is critical, as it prevents unwanted side reactions with combustion gases, ensuring the purity of the resulting material.

The Furnace's Role in Sintering

Sintering is the process that gives many ceramic and metallic parts their final strength and density.

What is Sintering?

Sintering is the process of compacting and forming a solid mass of material by heat and/or pressure, without melting it to the point of liquefaction.

A fine powder is heated to a temperature where the atoms in the particles diffuse across the boundaries, fusing the particles together and creating a single, solid piece.

Why the Muffle Furnace is Critical

Successful sintering depends entirely on precise temperature control. The muffle furnace excels here, allowing for programmable heating ramps and soak times.

The uniform heating ensures that the entire part sinters evenly, preventing weak spots or warping. This is vital for producing high-performance ceramics, glass, or composite components with consistent density and mechanical properties.

Understanding the Limitations

While highly effective, the muffle furnace is not without its trade-offs. Understanding these is key to its proper application.

Slower Heating Rates

Because the heat must radiate through the muffle walls, heating and cooling cycles are generally slower than in direct-fired kilns. This makes them less suitable for processes requiring rapid thermal shock.

Size and Scale Constraints

Muffle furnaces are typically used for laboratory-scale testing, research, and small-batch specialty production. Their complex construction and indirect heating method make them less economical for large-scale industrial bulk processing compared to tunnel kilns.

Energy Consumption

Maintaining high temperatures in an insulated box through electrical resistance is energy-intensive. For very large parts or continuous production, the operational cost can be a significant factor.

Making the Right Choice for Your Goal

The use of a muffle furnace for calcination or sintering depends on your final objective.

- If your primary focus is material purification: You will use the furnace for calcination to drive off volatiles and create a pure, stable precursor powder.

- If your primary focus is creating a dense, solid part from powder: You will use the furnace for sintering to fuse a pre-formed powder compact into its final, solid state.

- If your primary focus is producing high-performance ceramics: You will likely use the furnace for both processes sequentially—first calcining the raw materials, then pressing the powder and sintering the part.

Ultimately, the muffle furnace provides the precise, clean, and uniform thermal environment that makes these advanced material transformations possible.

Summary Table:

| Process | Key Role of Muffle Furnace | Benefits |

|---|---|---|

| Calcination | Provides stable, uniform heat for thermal decomposition | Ensures purity by preventing contamination, drives off volatiles |

| Sintering | Offers precise temperature control for particle fusion | Achieves even sintering, prevents weak spots and warping |

| General Use | Indirect heating in an isolated chamber | Maintains clean atmosphere, supports material integrity |

Unlock the full potential of your material processing with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for calcination, sintering, and beyond.

Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis