At its core, a controlled atmosphere box furnace is used for heat-treating to manage the chemical environment surrounding a part at high temperatures. This control is critical because it prevents unwanted surface reactions like oxidation and, in some cases, intentionally introduces specific elements to alter the material's surface properties in a predictable way.

The fundamental challenge of heat treatment is that high temperatures make metals highly reactive with the air around them. A controlled atmosphere furnace replaces reactive air with a specific, non-reactive or intentionally reactive gas, transforming the process from an unpredictable art into a precise science of material engineering.

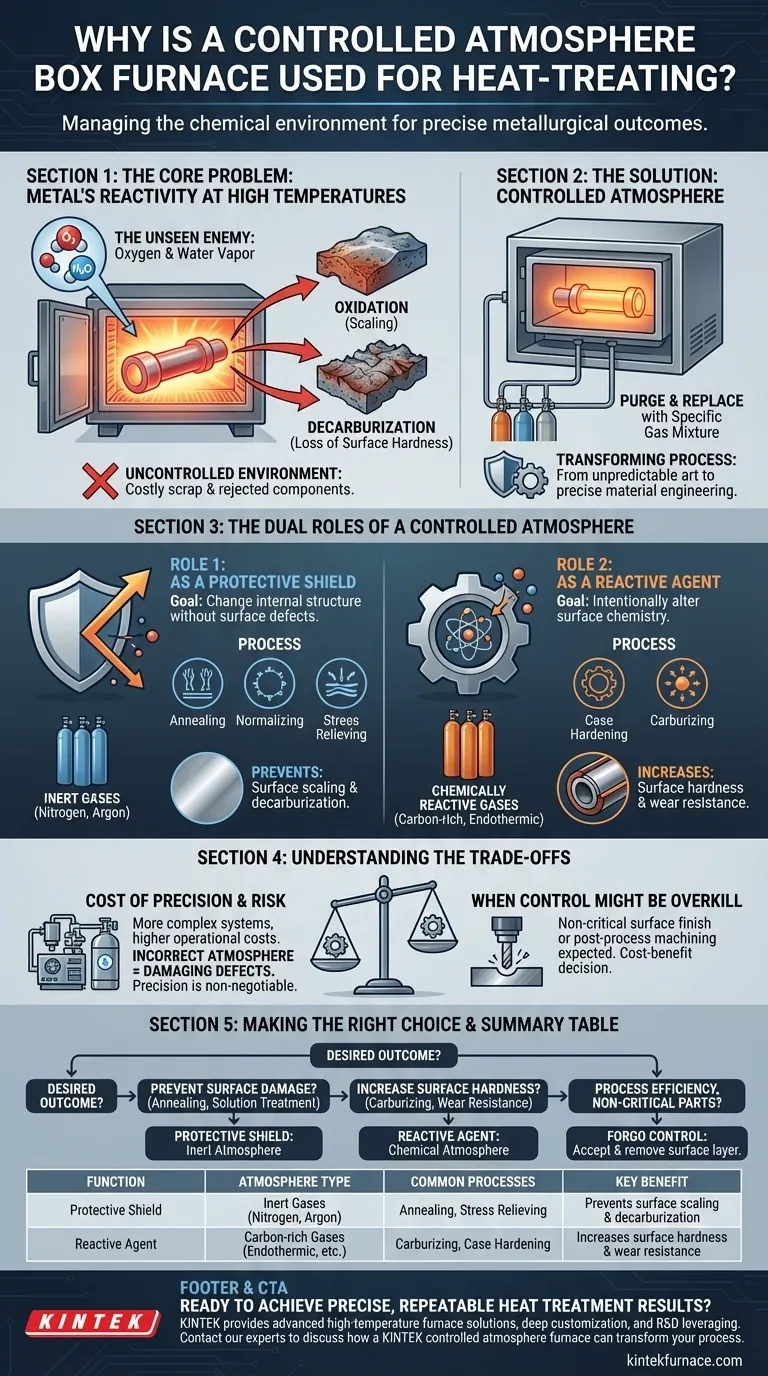

The Core Problem: Metal's Reactivity at High Temperatures

Heat treatment is essential for achieving the desired mechanical properties in metal parts, such as hardness, softness, or stress relief. This is accomplished by heating and cooling the material in a precise cycle.

The Unseen Enemy: The Atmosphere

At the high temperatures required for heat treatment, metals are extremely vulnerable to chemical reactions with elements in the ambient air, primarily oxygen and water vapor.

Without control, these reactions are unavoidable and can permanently damage the workpiece. The furnace's sealed chamber is designed to purge the ambient air and replace it with a specific gas mixture.

The Consequences of an Uncontrolled Environment

Leaving a part exposed to air during high-temperature treatment can lead to severe defects. These include oxidation (scaling), decarburization (loss of carbon and surface hardness), and other chemical changes.

These defects can compromise the part's structural integrity, dimensional accuracy, and performance, often resulting in costly scrap and rejected components.

The Dual Roles of a Controlled Atmosphere

The atmosphere inside the furnace is not just a passive element; it serves one of two distinct and critical functions depending on the process goal.

Role 1: As a Protective Shield

For processes like annealing (softening), normalizing, and stress relieving, the primary goal is to change the material's internal structure without affecting its surface.

In this case, a protective atmosphere made of inert gases (like nitrogen or argon) is used. This gas acts as a shield, preventing oxygen and other reactive elements from coming into contact with the hot metal surface.

Role 2: As a Reactive Agent

For processes like case hardening (carburizing), the goal is to intentionally alter the chemistry of the part's surface to make it harder than the core.

Here, a chemically reactive atmosphere is used. A gas mixture rich in carbon, for example, will diffuse carbon atoms into the surface of the steel, creating a hard, wear-resistant outer layer while the core remains tough and ductile.

Understanding the Trade-offs

While essential for quality, implementing a controlled atmosphere introduces complexity and requires careful consideration.

The Cost of Precision

Controlled atmosphere furnaces are more complex and expensive to operate than simple air furnaces. They require tightly sealed chambers, sophisticated gas mixing and monitoring systems, and a continuous supply of high-purity gases.

The Risk of an Incorrect Atmosphere

Using the wrong gas mixture can be just as damaging as using no controlled atmosphere at all. For example, an improperly balanced carburizing atmosphere can lead to soot formation or unwanted phases in the steel. Precision is non-negotiable.

When Control Might Be Overkill

If a part's surface finish is not critical, or if it will undergo significant post-process machining that removes the entire surface layer, a simpler furnace without atmospheric controls may be sufficient. This is a cost-benefit decision that depends entirely on the part's final application.

Making the Right Choice for Your Process

The furnace atmosphere is a powerful tool. Your choice should be directly guided by the desired metallurgical outcome for your workpiece.

- If your primary focus is preventing surface damage during annealing or solution treatment: Your goal is protection, requiring an inert atmosphere like nitrogen or argon.

- If your primary focus is increasing surface hardness for wear resistance: Your goal is a chemical reaction, requiring a reactive atmosphere like an endothermic or nitrogen-methanol mix.

- If your primary focus is process efficiency for non-critical parts: You may forgo atmospheric control, but only if you accept that a surface layer will be damaged and must be removed later.

Ultimately, mastering the furnace atmosphere is what elevates heat treatment from a simple heating cycle into a precise and repeatable engineering process.

Summary Table:

| Function | Atmosphere Type | Common Processes | Key Benefit |

|---|---|---|---|

| Protective Shield | Inert Gases (Nitrogen, Argon) | Annealing, Stress Relieving | Prevents surface scaling & decarburization |

| Reactive Agent | Carbon-rich Gases (Endothermic, etc.) | Carburizing, Case Hardening | Increases surface hardness & wear resistance |

Ready to achieve precise, repeatable heat treatment results?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique thermal processing requirements.

Contact our experts today to discuss how a KINTEK controlled atmosphere furnace can transform your heat-treating process.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance