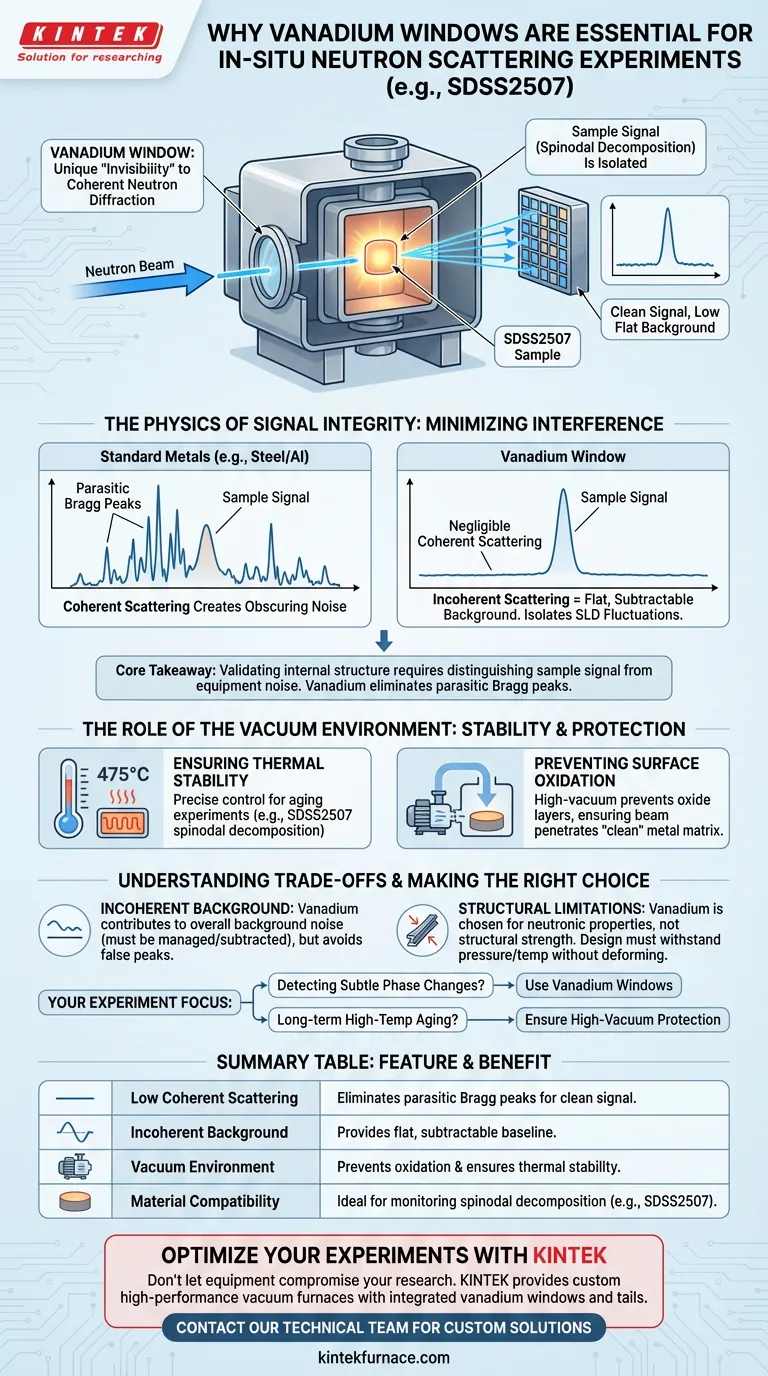

Vanadium windows are chosen primarily for their unique "invisibility" to neutron diffraction. This is because vanadium possesses an extremely small coherent scattering cross-section, which results in a very low and flat background signal. By using vanadium, the neutron beam can pass through the furnace walls with minimal interference, allowing the detectors to isolate the scattering caused by the specimen itself.

Core Takeaway Validating the internal structure of materials like SDSS2507 requires distinguishing the sample's signal from the equipment. Vanadium windows are essential because they eliminate parasitic "Bragg peaks" (interference patterns), ensuring that detected intensity fluctuations strictly reflect the internal phase separation of the material being studied.

The Physics of Signal Integrity

Minimizing Coherent Scattering

Standard structural metals used in furnaces, such as steel or aluminum, scatter neutrons in a coherent pattern. This creates distinct diffraction peaks that can overlap with and obscure the data from the sample.

Vanadium is unique because its coherent scattering length is negligible. Instead of creating interfering peaks, it scatters neutrons incoherently. This produces a flat, featureless background that is easily subtracted from the final data.

Isolating Scattering Length Density (SLD)

For materials like Super Duplex Stainless Steel (SDSS2507), the goal is to observe spinodal decomposition. This is a subtle phase separation process that changes the internal Scattering Length Density (SLD).

Because the vanadium window does not diffract the beam, researchers can be confident that any changes in scattering intensity are caused by these SLD fluctuations within the SDSS2507, rather than artifacts from the furnace environment.

The Role of the Vacuum Environment

Ensuring Thermal Stability

The vacuum furnace system provides the precise thermal control necessary for aging experiments.

For SDSS2507, this often involves maintaining a temperature of 475°C to accelerate the aging process. The furnace ensures the sample remains at this exact point to trigger the relevant atomic dynamics.

Preventing Surface Oxidation

The vacuum environment serves a second critical function: high-vacuum protection.

At high temperatures, stainless steel is prone to oxidation. The vacuum prevents oxide layers from forming on the surface of the SDSS2507. This ensures the neutron beam penetrates a "clean" metal matrix, allowing for the continuous, real-time monitoring of deep internal changes without surface interference.

Understanding the Trade-offs

Incoherent Scattering Background

While vanadium avoids coherent diffraction (peaks), it is not perfectly transparent. It has a high incoherent scattering cross-section.

This means that while it won't create false peaks, it does contribute to the overall background noise level. If the sample signal is extremely weak, this background noise must be carefully managed and subtracted during data analysis.

Structural Limitations

Vanadium is chosen for its neutronic properties, not its structural superiority.

In high-temperature applications, vanadium windows must be carefully designed to withstand the pressure differential of the vacuum without deforming, as it may not possess the same high-temperature creep resistance as specific superalloys used in other parts of the furnace.

Making the Right Choice for Your Experiment

To ensure the success of an in-situ neutron scattering experiment, consider the following regarding your equipment setup:

- If your primary focus is detecting subtle phase changes: Ensure your furnace utilizes vanadium tails or windows to eliminate Bragg peak interference that could mask microstructural evolution.

- If your primary focus is long-term high-temperature aging: Confirm the system offers high-vacuum protection to prevent surface oxidation from skewing the scattering data over time.

By coupling vanadium windows with a high-vacuum environment, you ensure that the data you collect is a true representation of your material's internal dynamics.

Summary Table:

| Feature | Benefit for In-Situ Experiments |

|---|---|

| Low Coherent Scattering | Eliminates parasitic Bragg peaks (interference) for a clean sample signal. |

| Incoherent Background | Provides a flat, easily subtracted baseline for precise data analysis. |

| Vacuum Environment | Prevents surface oxidation and ensures thermal stability at 475°C+. |

| Material Compatibility | Ideal for monitoring spinodal decomposition in metals like SDSS2507. |

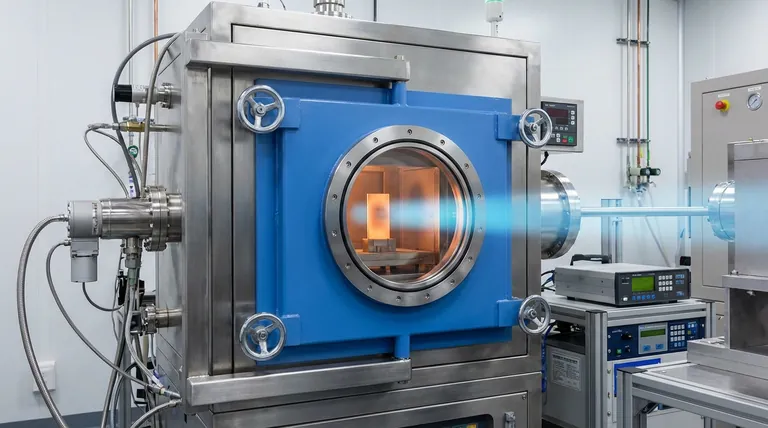

Optimize Your Neutron Scattering Experiments with KINTEK

Don't let equipment interference compromise your materials research. KINTEK provides high-performance vacuum furnaces specifically engineered for sensitive in-situ experiments. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to integrate vanadium windows and specialized tails for your unique neutron scattering needs.

Ensure your data reflects the true internal dynamics of your samples. Contact our technical team today to design a custom high-temperature solution for your lab.

Visual Guide

References

- Monika Rolinska, Peter Hedström. On the Modeling of Small-Angle Neutron Scattering Data to Analyze the Early Stage of Phase Separation in Fe-Cr-based Alloys. DOI: 10.1007/s13632-024-01156-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- What are the advantages of using vacuum filtration systems for calcium-based perrhenates? Expert Stability Guide

- What are the typical components of a vacuum system used in a high-temperature distillation furnace? Ensure Process Precision

- What role does a reduction furnace play in the activation of CuO-Fe3O4 catalysts? Master Catalyst Engineering

- What are the key steps in vacuum brazing? Master the 5-Step Process for Strong, Clean Joints

- How does vacuum sintering help in material purification? Achieve Superior Purity and Performance

- Why is a vacuum high-temperature box furnace critical for Ti-11Cr alloys? Ensure High Purity Homogenization

- What role does the vacuum system play in the vacuum sintering process? Enhance Glass-Ceramic Density and Strength

- Why use vacuum and argon in pulse solidification? Protect your Aluminum-Silicon alloys from oxidation and contamination