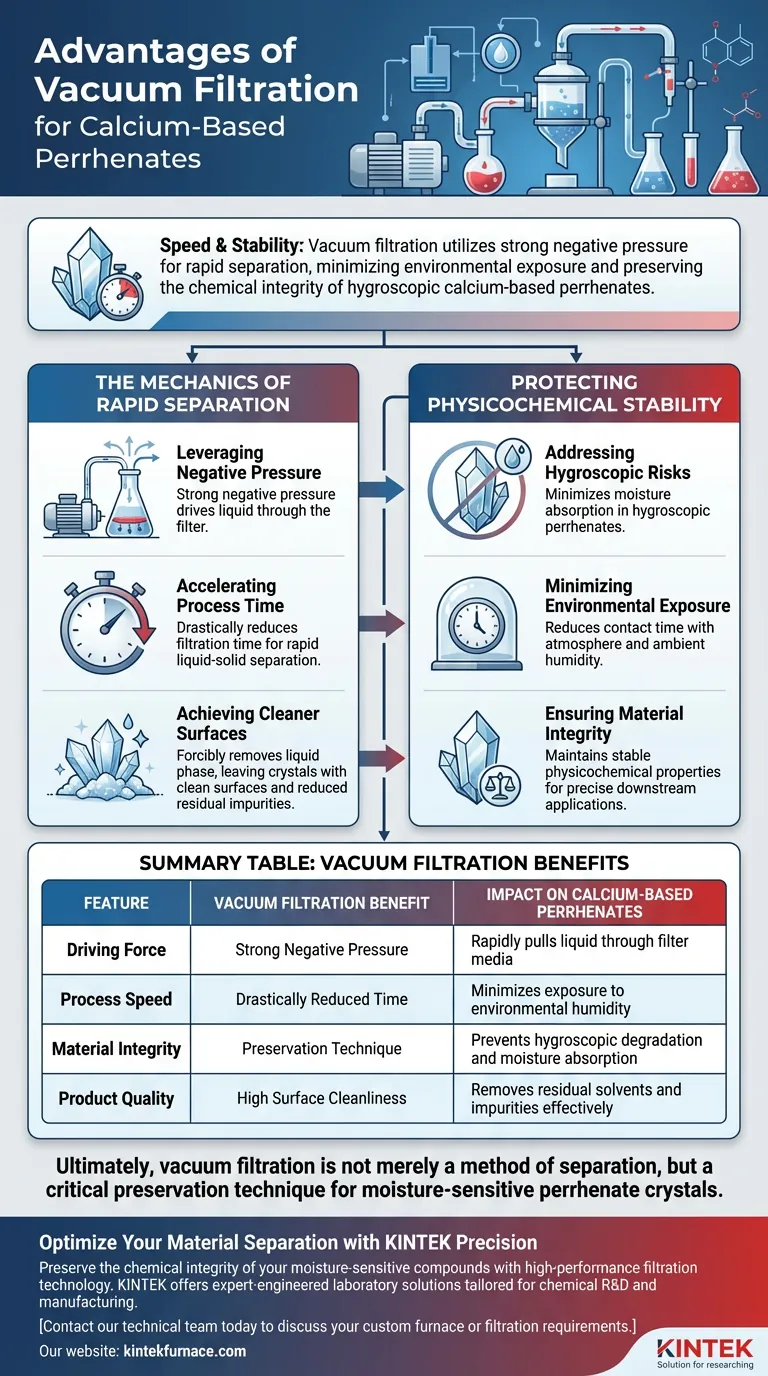

Vacuum filtration systems provide a decisive advantage by utilizing strong negative pressure to accelerate the separation of crystals from the mother liquor. This rapid processing is essential for minimizing the exposure of calcium-based perrhenates to the environment, thereby preserving their chemical integrity and ensuring surface cleanliness.

The core benefit lies in the relationship between speed and stability. Because calcium-based perrhenates are hygroscopic, the rapid separation provided by vacuum filtration minimizes contact with humid air, preventing moisture absorption that would otherwise compromise the physicochemical properties of the crystals.

The Mechanics of Rapid Separation

Leveraging Negative Pressure

Vacuum filtration systems do not rely on gravity alone; they generate a strong negative pressure driving force. This differential pressure actively pulls liquid through the filter medium.

Accelerating Process Time

The primary operational benefit is the drastic reduction in filtration time. This allows for the rapid separation of solid crystals from the surrounding mother liquor.

Achieving Cleaner Surfaces

By forcibly removing the liquid phase, the system leaves behind crystals with clean surfaces. This reduces the amount of residual solvent or impurities clinging to the final product.

Protecting Physicochemical Stability

Addressing Hygroscopic Risks

Calcium-based perrhenate crystals are hygroscopic, meaning they have a tendency to absorb moisture from the surrounding environment. If left exposed during a slow filtration process, the quality of the crystal degrades.

Minimizing Environmental Exposure

The speed of vacuum filtration is a quality control measure, not just a time-saver. By minimizing the contact time with the atmosphere, the system prevents the crystals from reacting with ambient humidity.

Ensuring Material Integrity

Rapid isolation ensures the crystals maintain stable physicochemical properties. This is critical for downstream applications where precise chemical composition and surface characteristics are required.

Operational Considerations and Trade-offs

Equipment Complexity

Unlike simple gravity filtration, vacuum systems require pumps, seals, and pressure-rated vessels. This introduces a layer of mechanical complexity and maintenance requirements to the workflow.

Managing Seal Integrity

To maintain the necessary pressure differential, system integrity is paramount. Leaks in the vacuum line can reduce efficiency and potentially re-introduce contaminants or moisture into the process.

Making the Right Choice for Your Goal

To determine if vacuum filtration is necessary for your specific application, consider your primary constraints:

- If your primary focus is Crystal Purity: Prioritize vacuum filtration to minimize environmental exposure and prevent moisture absorption in hygroscopic materials.

- If your primary focus is Process Efficiency: Implement vacuum systems to significantly reduce the time required for liquid-solid separation compared to gravity methods.

Ultimately, vacuum filtration is not merely a method of separation, but a critical preservation technique for moisture-sensitive perrhenate crystals.

Summary Table:

| Feature | Vacuum Filtration Benefit | Impact on Calcium-based Perrhenates |

|---|---|---|

| Driving Force | Strong Negative Pressure | Rapidly pulls liquid through filter media |

| Process Speed | Drastically Reduced Time | Minimizes exposure to environmental humidity |

| Material Integrity | Preservation Technique | Prevents hygroscopic degradation and moisture absorption |

| Product Quality | High Surface Cleanliness | Removes residual solvents and impurities effectively |

Optimize Your Material Separation with KINTEK Precision

Preserve the chemical integrity of your moisture-sensitive compounds with high-performance filtration technology. KINTEK provides expert-engineered laboratory solutions tailored to the rigorous demands of chemical R&D and manufacturing.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab equipment, all customizable for your unique processing needs. Whether you are handling hygroscopic perrhenates or advanced ceramic slurries, our systems ensure maximum stability and purity.

Contact our technical team today to discuss your custom furnace or filtration requirements.

Visual Guide

References

- New calcium perrhenates: synthesis and crystal structures of Ca(ReO<sub>4</sub>)<sub>2</sub> and K<sub>2</sub>Ca<sub>3</sub>(ReO<sub>4</sub>)<sub>8</sub>·4H<sub>2</sub>O. DOI: 10.1515/zkri-2025-0008

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the significance of using a vacuum diffusion annealing furnace for thermodynamic equilibrium studies in alloys?

- How are vacuum furnaces classified based on chamber design? Explore Horizontal, Vertical, and Bottom-Loading Types

- How does a vacuum furnace improve material purity? Achieve Superior Material Integrity with Controlled Environments

- What is vacuum sintering and what are its advantages? Unlock Superior Material Performance

- How does a high vacuum furnace ensure the purity of Ti-Nb alloys? Expert Guide to Sintering and Debinding

- How does vacuum heat treating work in terms of temperature and time control? Master Precise Material Transformations

- What types of materials are commonly processed using vacuum tempering? Achieve Superior Surface Integrity and Mechanical Properties

- What safety benefits do vacuum furnaces offer? Inherently Safer High-Temperature Processing