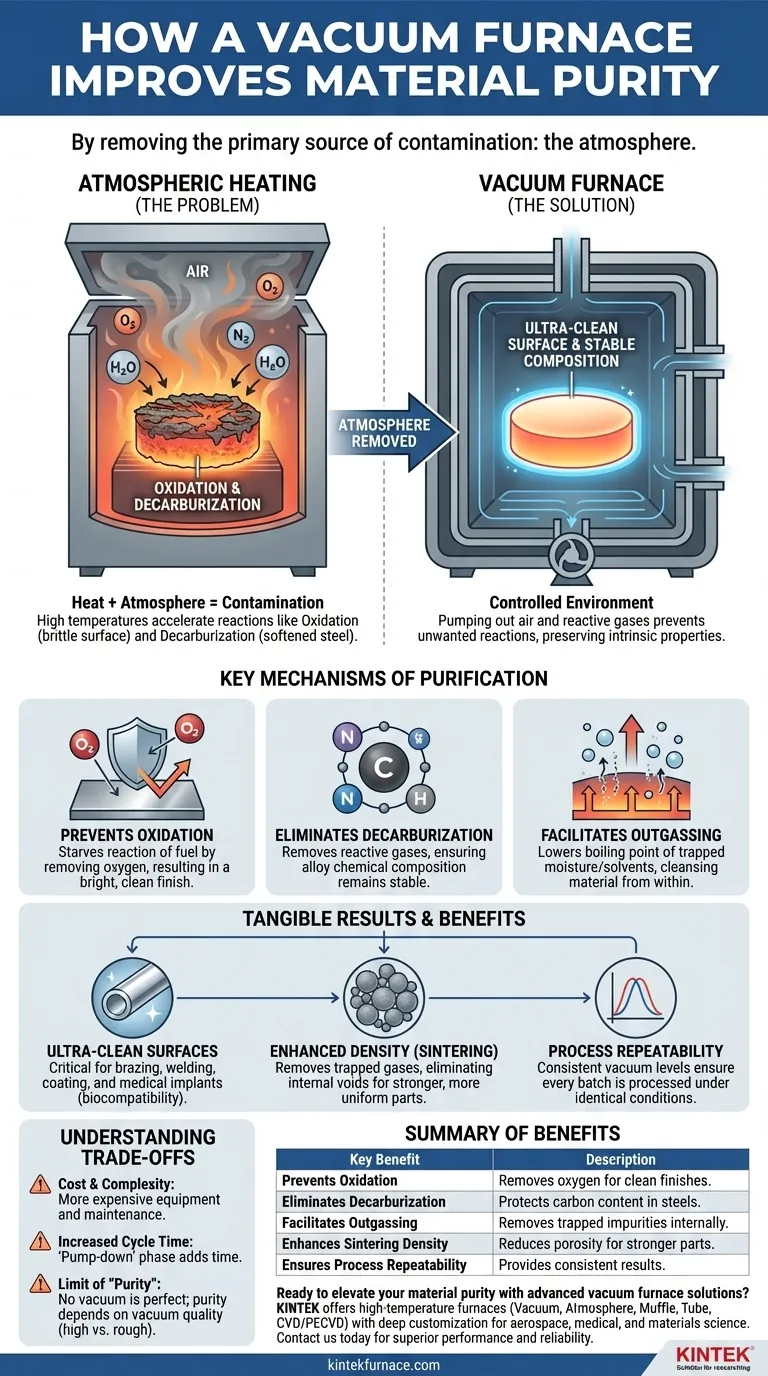

At its core, a vacuum furnace improves material purity by physically removing the primary source of contamination: the atmosphere. By pumping out air, moisture, and other reactive gases before heating, the furnace creates a controlled environment where unwanted chemical reactions, such as oxidation, simply cannot occur. This ensures the material's intrinsic properties are preserved or enhanced, not degraded by its surroundings.

The fundamental purpose of a vacuum furnace is not just to heat a material, but to isolate it from a reactive environment. High temperatures dramatically accelerate chemical reactions, and removing the reactants—chiefly oxygen, nitrogen, and water vapor—is the most effective way to guarantee the material's final purity and structural integrity.

The Problem: Why Heat Invites Contamination

Heating a material in the presence of air is like intentionally exposing it to a host of contaminants. The elevated temperature acts as a catalyst, speeding up undesirable reactions that can permanently alter the material's composition and performance.

Oxidation: The Primary Threat

Oxidation is the most common reaction that occurs during atmospheric heating. When hot, most metals will readily react with oxygen in the air, forming a brittle, flaky layer of oxide on the surface.

A vacuum environment starves this reaction of its fuel. By removing the vast majority of oxygen molecules from the chamber, the furnace effectively prevents oxidation, resulting in a bright, clean surface finish.

Decarburization and Other Reactions

Beyond oxygen, other atmospheric gases can cause harm. For certain steel alloys, nitrogen and hydrogen can react with carbon near the material's surface, a process called decarburization. This depletes the carbon content, which can soften the steel and compromise its strength.

A vacuum eliminates these reactive gases, ensuring the alloy's chemical composition remains stable and uniform from its core to its surface.

Outgassing: Removing Trapped Impurities

Materials themselves contain trapped moisture, solvents, and other volatile compounds. A vacuum lowers the boiling point of these substances, causing them to "boil off" and be pulled out of the material at much lower temperatures.

This process, known as outgassing, effectively cleanses the material from within before the critical high-temperature phase even begins.

The Results of a Vacuum Environment

By preventing these unwanted reactions, a vacuum furnace delivers tangible improvements in the final product. The benefits go far beyond just a clean surface.

Achieving Ultra-Clean Surfaces

The absence of oxidation and other surface reactions results in an exceptionally clean finish. This is critical for parts that require subsequent processes like brazing, welding, or coating, as a pure surface ensures a stronger, more reliable bond.

For medical implants, this cleanliness is essential for biocompatibility and preventing adverse reactions within the body.

Enhancing Internal Structure and Density

During processes like sintering (fusing powdered material together with heat), a vacuum helps pull out gases trapped between the particles.

Removing these trapped gases eliminates the potential for internal voids or porosity, leading to a denser, more structurally uniform final part with superior mechanical properties.

Ensuring Process Repeatability

The composition of ambient air can vary with humidity and weather. A vacuum, however, is a highly controllable and consistent environment.

By pumping the chamber to a specific, measurable pressure level every time, you ensure that each batch is processed under identical conditions, leading to highly repeatable and predictable results.

Understanding the Trade-offs

While powerful, vacuum furnace technology is not a universal solution. Its benefits must be weighed against practical considerations.

Cost and Complexity

Vacuum furnaces are significantly more complex and expensive to purchase and maintain than standard atmospheric furnaces. They require robust vacuum pumps, seals, and control systems that add to the operational overhead.

Increased Cycle Time

Achieving a deep vacuum is not instantaneous. The "pump-down" phase, where air is evacuated from the chamber, adds time to the overall process cycle. For some high-volume applications, this can be a limiting factor.

The Limit of "Purity"

No vacuum is perfect; there will always be some remaining molecules in the chamber. The level of purity achieved is directly related to the quality of the vacuum (measured in Torr or mbar). Critical applications in aerospace or semiconductors may require a "high vacuum," which takes longer and requires more sophisticated equipment than a "rough vacuum" used for basic heat treating.

How to Apply This to Your Project

Your choice of thermal processing should be dictated by the end goal for your material.

- If your primary focus is maximum purity for electronics or medical devices: A high-vacuum furnace is non-negotiable. You will likely need a system capable of very low pressures and may benefit from multiple pump-down and backfill cycles to purge residual gases.

- If your primary focus is preventing surface oxidation for better brazing or coating: A medium-vacuum environment is often sufficient. The key is removing enough oxygen to maintain a clean, active surface for bonding.

- If your primary focus is achieving maximum density in sintered parts: The vacuum's ability to facilitate outgassing is your main advantage. This ensures trapped gases don't create internal voids that weaken the final component.

Ultimately, using a vacuum furnace is a deliberate choice to control a material's environment, thereby controlling its final properties.

Summary Table:

| Key Benefit | Description |

|---|---|

| Prevents Oxidation | Removes oxygen to avoid surface reactions, ensuring clean finishes. |

| Eliminates Decarburization | Protects carbon content in steels by removing reactive gases like nitrogen. |

| Facilitates Outgassing | Removes trapped impurities from materials, improving internal purity. |

| Enhances Sintering Density | Reduces porosity for stronger, more uniform parts. |

| Ensures Process Repeatability | Provides consistent vacuum levels for reliable results. |

Ready to elevate your material purity with advanced vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver high-temperature furnaces tailored to your needs. Our product line includes Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, all backed by deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical devices, or materials science, we ensure superior performance and reliability. Contact us today to discuss how we can enhance your lab's efficiency and achieve unparalleled results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance