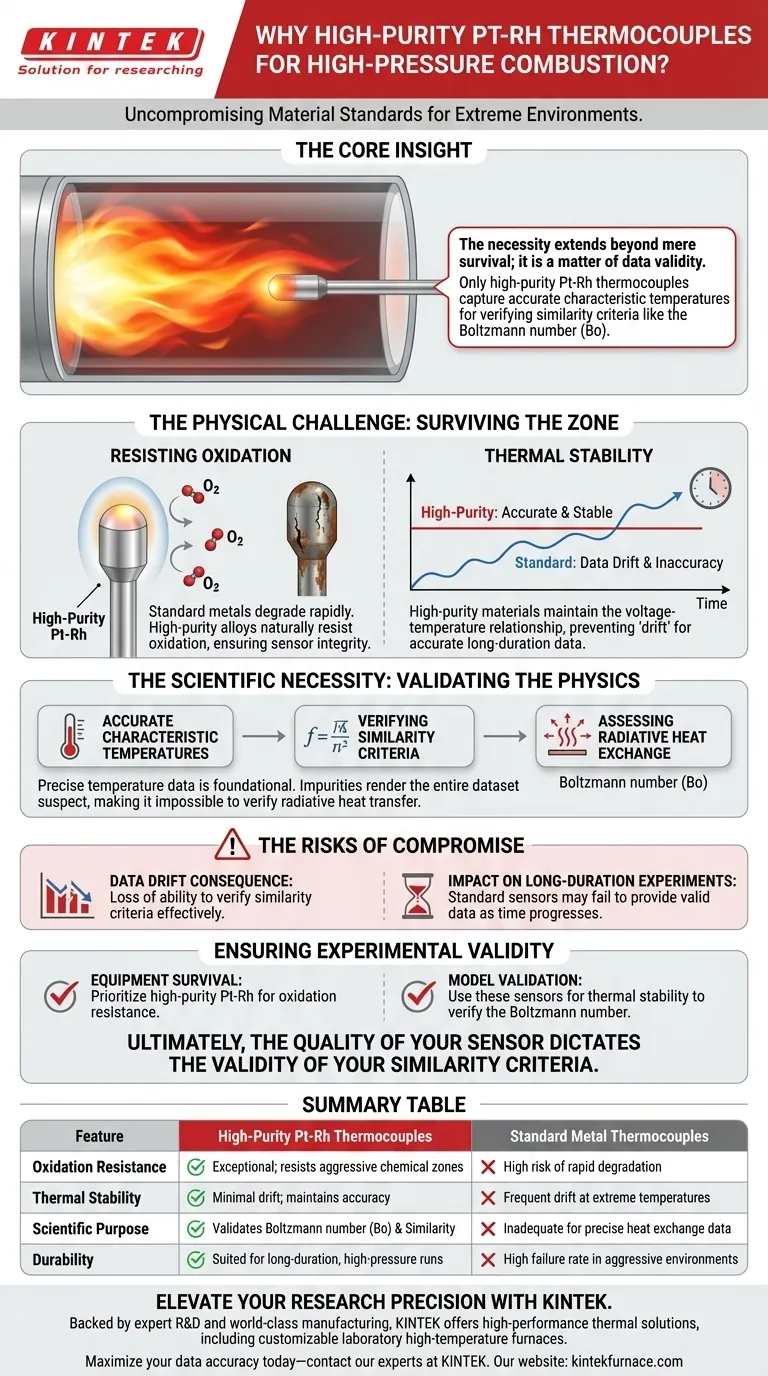

High-pressure combustion environments demand uncompromising material standards. You require high-purity platinum-rhodium thermocouples specifically for their exceptional thermal stability and oxidation resistance. Standard sensors typically fail to maintain accuracy or structural integrity when exposed to the extreme temperatures and aggressive chemical conditions of a combustion zone.

The Core Insight The necessity of these sensors extends beyond mere survival; it is a matter of data validity. High-purity platinum-rhodium thermocouples are the only reliable way to capture accurate characteristic temperatures over time, which are required to verify critical similarity criteria like the Boltzmann number (Bo).

The Physical Challenge: Surviving the Zone

Resisting Oxidation

The interior of a high-pressure combustion chamber is a chemically aggressive environment.

Standard metals degrade rapidly when exposed to oxygen at these extreme temperatures. High-purity platinum-rhodium alloys are essential because they naturally resist this oxidation, ensuring the sensor remains intact throughout the experiment.

Thermal Stability

Survival is not enough; the sensor must remain stable.

In lower-quality thermocouples, extreme heat can alter the voltage-temperature relationship, causing "drift." High-purity materials maintain their thermal stability, ensuring that the temperature reading taken at the end of the experiment is just as accurate as the one taken at the start.

The Scientific Necessity: Validating the Physics

Capturing Characteristic Temperatures

To understand the behavior of the combustion chamber, you need precise data points known as characteristic temperatures.

These values serve as the foundational inputs for your analysis. If the sensor degrades or drifts due to impurities, these inputs become unreliable, rendering the entire dataset suspect.

Verifying Similarity Criteria

Combustion experiments often rely on "similarity criteria" to scale results or validate models.

The primary reference highlights the importance of verifying the Boltzmann number (Bo). This dimensionless number is critical for characterizing the system's behavior, particularly regarding heat transfer.

Assessing Radiative Heat Exchange

The Boltzmann number specifically relates to radiative heat exchange.

Accurate temperature data is vital to calculating this number correctly. Without the precision provided by high-purity platinum-rhodium sensors, you cannot accurately verify the radiative heat transfer properties of your combustion system.

The Risks of Compromise

The Consequence of Data Drift

The primary trade-off in selecting these sensors is the strict requirement for purity over cost or availability.

Attempting to use lower-grade sensors introduces the risk of unmeasured drift. If the sensor drifts, you lose the ability to verify the similarity criteria effectively.

Impact on Long-Duration Experiments

The reference notes that these sensors are critical for obtaining data "over extended periods."

If your experiment requires long-duration data collection, a standard sensor may survive the initial ignition but fail to provide valid data as time progresses. The high-purity requirement is a safeguard against the degradation of data quality over time.

Ensuring Experimental Validity

To ensure your high-pressure combustion data is scientifically sound, apply the following principles:

- If your primary focus is Equipment Survival: Prioritize high-purity platinum-rhodium for its superior oxidation resistance to prevents physical sensor failure.

- If your primary focus is Model Validation: You must use these sensors to ensure the thermal stability required to verify the Boltzmann number and radiative heat exchange.

Ultimately, the quality of your sensor dictates the validity of your similarity criteria.

Summary Table:

| Feature | High-Purity Pt-Rh Thermocouples | Standard Metal Thermocouples |

|---|---|---|

| Oxidation Resistance | Exceptional; resists aggressive chemical zones | High risk of rapid degradation |

| Thermal Stability | Minimal drift; maintains voltage-temp accuracy | Frequent drift at extreme temperatures |

| Scientific Purpose | Validates Boltzmann number (Bo) & Similarity | Inadequate for precise heat exchange data |

| Durability | Suited for long-duration, high-pressure runs | High failure rate in aggressive environments |

Elevate Your Research Precision with KINTEK

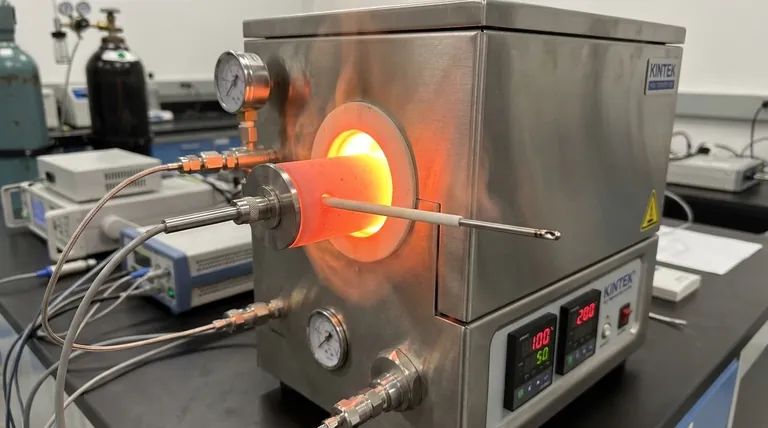

Don't let data drift compromise your scientific validity. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance thermal solutions for the most demanding environments. Whether you need specialized sensors or custom Muffle, Tube, Rotary, Vacuum, or CVD systems, our laboratory high-temperature furnaces are fully customizable to meet your unique experimental needs.

Maximize your data accuracy today—contact our experts at KINTEK to discuss your custom furnace requirements.

Visual Guide

References

- Sergey Osipov, Andrey Vegera. Influence of the experimental setup parameters on the deviation of the similarity criteria in the experimental study of the model boundary conditions from the similarity criteria of the full-scale combustion chamber. DOI: 10.59429/ace.v8i1.5645

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the main differences in performance between MoSi2 and SiC heating elements? Choose the Right Element for Your High-Temp Needs

- What are the common materials used for high-temperature heating elements? Choose the Right Element for Your Process

- What are precious metals used as high-temperature heating elements? Essential for Extreme Heat Applications

- What precautions should be taken when installing silicon carbide heating elements? Ensure Longevity and Safety

- What is MoSi2 heating element? A Guide to Extreme-Temperature Stability Up to 1800°C

- Are silicon carbide heating elements customizable? Optimize Your High-Temp Furnace Performance

- What recent advancements have been made in MoSi2 heating elements? Optimize for Extreme Temperatures and Reactive Atmospheres

- How do MoSi2 heating elements perform in terms of heating and cooling cycles? Discover Rapid Thermal Cycling Benefits