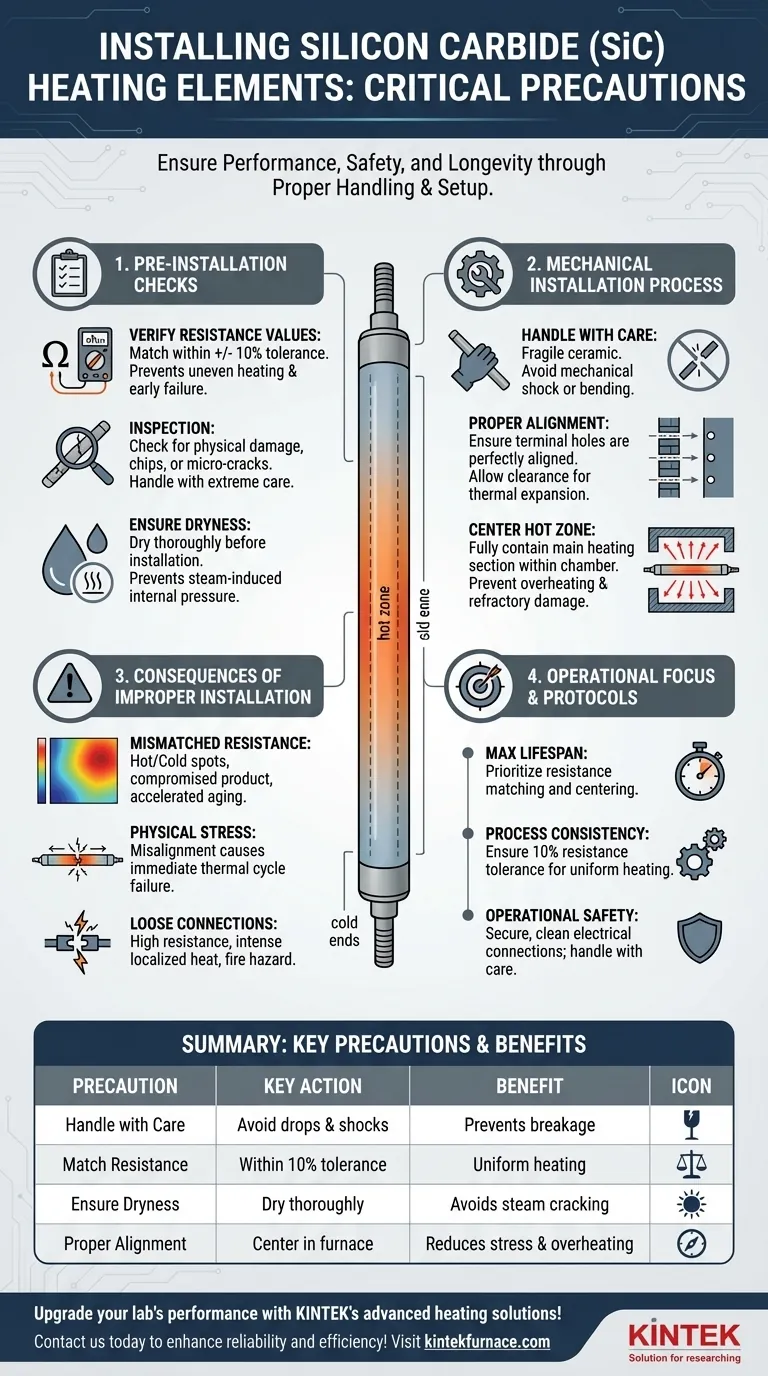

When installing silicon carbide (SiC) heating elements, the most critical precautions are to handle them with extreme care due to their brittle nature, match the electrical resistance of all elements within a 10% tolerance, ensure they are perfectly dry before installation, and guarantee proper alignment and centering within the furnace chamber to prevent mechanical stress and localized overheating.

Proper installation is not merely a mechanical task; it is a critical process that directly dictates furnace temperature uniformity, operational safety, and the ultimate lifespan of the heating elements. Overlooking these steps can lead to premature failure and costly downtime.

Pre-Installation Checks: Foundation for Success

Before an element even enters the furnace, a few preparatory steps are essential to prevent immediate or future failure. These checks ensure you are starting with a viable component.

Verify Resistance Values

Each SiC element has a specific electrical resistance. For uniform heating, all elements connected in a single electrical bank must have resistances that match within a +/- 10% tolerance.

Mismatched resistances cause some elements to run hotter than others, leading to uneven furnace temperatures and dramatically shortening the life of the overworked elements.

Inspect for Physical Damage

Silicon carbide is extremely hard but also very brittle, like a ceramic coffee mug. Carefully inspect each new element for any chips, cracks, or other signs of damage that may have occurred during shipping or handling.

A small, invisible micro-crack can become a catastrophic failure point once the element is subjected to high temperatures and thermal cycling.

Ensure Elements are Dry

Avoid installing SiC elements in damp or humid conditions. If there is any suspicion that an element has been exposed to moisture, it must be dried thoroughly before installation and use.

Heating a damp element can cause the trapped moisture to turn to steam, potentially creating internal pressure that cracks the element from within.

The Mechanical Installation Process

The physical placement of the element inside the furnace is a moment where precision prevents future problems.

Handle with Extreme Care

Always handle the elements as fragile ceramic components. Never drop, knock, or subject them to mechanical shock or bending forces.

Ensure Proper Alignment and Clearance

The terminal holes in the furnace wall or insulation must be perfectly aligned. The element should slide smoothly into place without being forced or striking the refractory on the opposite side.

Forcing an element into a misaligned hole creates internal stresses that will cause it to fail under heat. There must be adequate clearance to allow for thermal expansion during operation.

Center the Heating Section

The "hot zone," or the main heating section of the element, must be fully contained within the furnace chamber. No part of this section should reside inside the refractory brickwork.

If the heating section is inside the furnace wall, it cannot radiate heat effectively. This causes that portion of the element to overheat, while simultaneously damaging the surrounding refractory insulation.

Understanding the Consequences of Improper Installation

Skipping these precautions has direct and predictable consequences for your furnace's performance and reliability. These are not suggestions, but requirements for successful operation.

The Impact of Mismatched Resistance

Unbalanced resistance leads directly to hot and cold spots in your furnace. This compromises product quality and causes the hotter-running elements to age and fail much faster, triggering a chain reaction of replacements.

The Danger of Physical Stress

An element installed under mechanical tension from misalignment is a ticking time bomb. The first thermal cycle can be enough to expand and break it, causing an immediate shutdown.

The Cost of Loose Connections

The connection points between the element's cold ends and the power straps are critical. The references specify ensuring clamps and strips contact the aluminum parts firmly.

A loose or dirty connection creates high electrical resistance, generating intense localized heat. This can destroy the connecting strap, damage the cold end of the element, and create a serious fire hazard.

Applying This to Your Furnace

Your installation protocol should be guided by your primary operational goal.

- If your primary focus is maximum element lifespan: Prioritize resistance matching between all elements and perfect centering of the hot zone away from the furnace wall.

- If your primary focus is process consistency: The single most important factor is verifying that all elements in a control zone are within the 10% resistance tolerance for uniform heating.

- If your primary focus is operational safety: Double-check that all electrical connections are clean and torqued correctly, and handle the brittle elements with extreme care to prevent breakage.

By treating installation as a precise technical procedure, you take direct control over your furnace's reliability and performance.

Summary Table:

| Precaution | Key Action | Benefit |

|---|---|---|

| Handle with Care | Avoid drops and shocks | Prevents breakage and cracks |

| Match Resistance | Ensure elements within 10% tolerance | Achieves uniform heating and longer life |

| Ensure Dryness | Dry thoroughly before installation | Avoids steam-induced cracking |

| Proper Alignment | Align and center in furnace | Reduces mechanical stress and overheating |

Upgrade your lab's performance with KINTEK's advanced heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to enhance reliability and efficiency in your operations!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis