In short, recent advancements in MoSi2 heating elements have focused on specialized designs and material grades rather than a fundamental change in the core material. This progress delivers optimized performance for specific, challenging industrial applications, moving beyond the general-purpose elements of the past. Modern MoSi2 elements are now tailored for extreme temperatures, reactive atmospheres, and processes where contamination is a critical concern.

The key takeaway is that the MoSi2 technology platform is mature. The latest innovations are not about reinventing the material, but about refining its manufacturing and design to solve specific, high-value problems that were previously difficult or impossible to address.

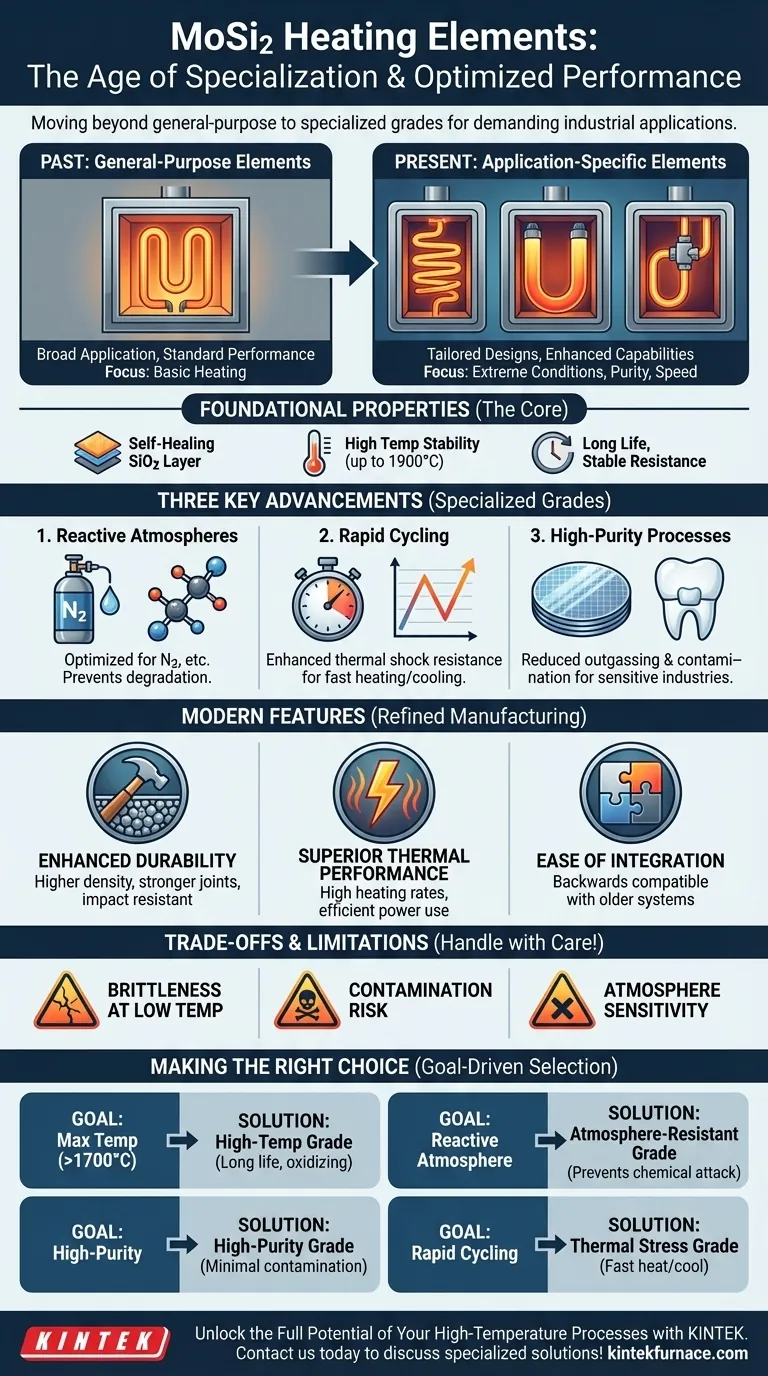

The Shift from General-Purpose to Application-Specific Elements

Molybdenum disilicide (MoSi2) has long been a benchmark for high-temperature electric heating. The core value proposition remains the same, but the technology has evolved to meet increasingly demanding process requirements.

Foundational Properties of MoSi2

The foundation of any MoSi2 element is its unique ability to form a protective, self-healing layer of amorphous silica (SiO2) on its surface when heated in an oxidizing atmosphere.

This protective layer is what gives the material its signature advantages:

- High Temperature Stability: Capable of continuous operation at furnace temperatures from 1600°C to 1700°C, with element surface temperatures reaching up to 1900°C.

- Long Life Expectancy: When operated correctly, particularly above 1500°C, they can last significantly longer than alternatives like Silicon Carbide (SiC).

- Stable Resistance: The electrical resistance of MoSi2 does not change significantly with age, ensuring consistent and predictable power output.

The Core Advancement: Optimized Grades and Geometries

Recent progress is defined by the development of elements engineered for specific hostile environments where standard elements would fail.

- For Reactive Atmospheres: New designs are optimized to perform at high temperatures in reactive atmospheres, such as nitrogen, which can degrade standard elements.

- For Rapid Cycling: Specialized elements are now available for applications that require rapid heating and cooling, like laboratory test furnaces and high-temperature sintering, without suffering premature failure from thermal shock.

- For Contamination-Sensitive Processes: High-purity grades have been developed for industries like semiconductor manufacturing or dental zirconia sintering, where any outgassing or element shedding can ruin the product.

Key Features of Modern MoSi2 Elements

These application-specific designs are made possible by refinements in the manufacturing process, resulting in elements with superior physical and thermal properties.

Enhanced Durability and Density

Modern elements feature a higher material density (+/- 5% porosity) and a refined grain structure. This results in superior physical strength (350 MPa bending strength) and resistance to chemical attack.

A key manufacturing advancement is the use of a special joint molding process for the terminals and heating section, creating a stronger, more impact-resistant element that is less prone to damage during installation or operation.

Superior Thermal Performance

The high electrical conductivity and refined material properties of modern MoSi2 elements allow for very high heating rates with relatively low power consumption. This efficiency is critical for both production speed and operational cost.

Ease of Integration and Replacement

A significant practical advantage is that new, advanced elements are typically compatible with older ones. This allows furnaces to be upgraded incrementally without requiring a full-scale replacement of all heating elements at once.

Understanding the Trade-offs and Limitations

Despite their advantages, choosing and using MoSi2 elements requires a clear understanding of their operational limits. Ignoring these can lead to premature failure.

Brittleness at Low Temperatures

Like most ceramic-based materials, MoSi2 is brittle and fragile at room temperature. Care must be taken during shipping, handling, and installation to avoid mechanical shock, which can easily cause fractures.

Risk of Contamination-Induced Failure

MoSi2 elements are highly susceptible to chemical attack from certain contaminants. Technicians must maintain furnaces correctly and avoid introducing reactive compounds.

A common failure mode occurs when "painted" or colored zirconia is fired without proper drying, causing vapors that attack the element's protective silica layer.

Sensitivity to Atmosphere

While specialized grades exist for reactive atmospheres, standard MoSi2 elements are designed for oxidizing environments. Using the wrong type of element in a reducing or nitrogen-rich atmosphere will lead to rapid degradation and failure.

Making the Right Choice for Your Goal

Selecting the correct MoSi2 heating element is no longer a one-size-fits-all decision. Your process goal should dictate your choice.

- If your primary focus is reaching the highest possible temperatures (>1700°C): Choose a high-temperature grade designed for maximum thermal load and long life in oxidizing atmospheres.

- If your primary focus is operating in a reactive or changing atmosphere: You must select a specialized, atmosphere-resistant grade to prevent chemical degradation of the element.

- If your primary focus is minimizing contamination in a high-purity process: Select a high-purity, high-density element specifically manufactured to reduce outgassing and particle shedding.

- If your primary focus is rapid thermal cycling: Opt for an element specifically engineered to withstand high thermal stress, which is common in laboratory and advanced sintering furnaces.

Ultimately, leveraging these advancements requires matching the right specialized element to your specific application.

Summary Table:

| Advancement Type | Key Features | Target Applications |

|---|---|---|

| Reactive Atmosphere Grades | Optimized for nitrogen-rich environments, prevents degradation | Industrial processes with reactive gases |

| Rapid Cycling Designs | Enhanced thermal shock resistance, supports fast heating/cooling | Laboratory test furnaces, high-temperature sintering |

| High-Purity Grades | Reduced outgassing and particle shedding, minimal contamination | Semiconductor manufacturing, dental zirconia sintering |

| Enhanced Durability | Higher density, refined grain structure, stronger joints | High-stress environments, improved lifespan |

Unlock the Full Potential of Your High-Temperature Processes with KINTEK

Are you facing challenges with extreme temperatures, reactive atmospheres, or contamination in your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced MoSi2 heating elements tailored to your unique needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your experimental requirements.

Contact us today to discuss how our specialized solutions can enhance your efficiency and performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability