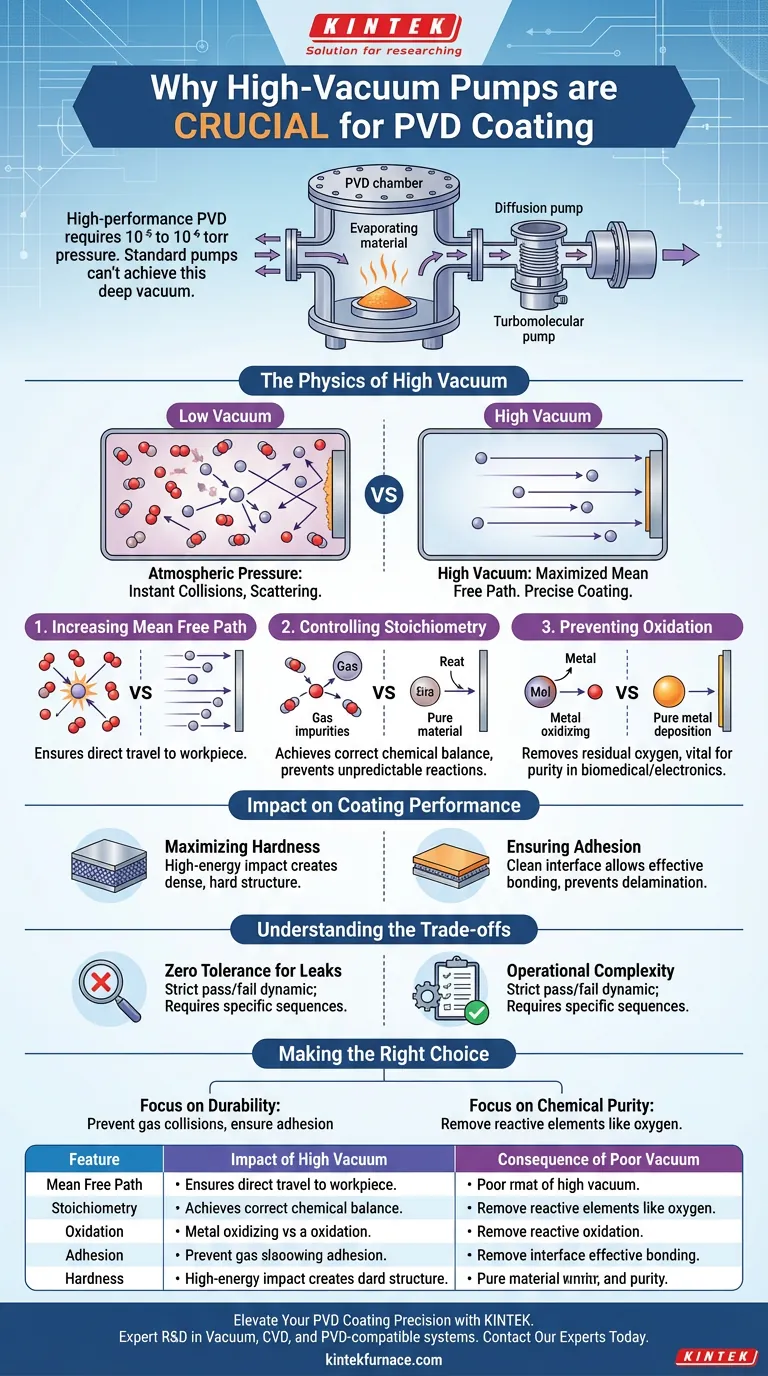

High-performance Physical Vapor Deposition (PVD) relies on creating an environment almost entirely void of air. Diffusion or turbomolecular pumps are mandatory components because they act as the secondary "high vacuum" stage, driving system pressure down to the critical range of $10^{-5}$ to $10^{-6}$ torr. Standard mechanical pumps cannot achieve this level of vacuum, which is required to strip away the final traces of background gas.

The primary role of these pumps is to maximize the mean free path of evaporated atoms. By creating a high vacuum, they prevent coating material from colliding with air molecules, ensuring the coating arrives at the target with precise chemistry, high hardness, and superior adhesion.

The Physics of High Vacuum in PVD

Increasing the Mean Free Path

In a PVD chamber, metal atoms (such as titanium, chromium, or aluminum) are evaporated and must travel to the workpiece.

At atmospheric pressure, these atoms would instantly collide with air molecules and scatter.

High vacuum pumps remove these obstacles, increasing the mean free path—the average distance an atom travels before hitting something else. This ensures the coating material travels in a straight line directly to the surface you are coating.

Controlling Stoichiometry

Achieving the correct chemical balance, or stoichiometric ratio, is impossible if the chamber contains random gas impurities.

If residual air is present, the coating atoms may react unpredictably before landing on the substrate.

Diffusion or turbomolecular pumps ensure that the only materials reacting on the workpiece surface are the ones you intended to put there.

Preventing Oxidation

Residual air contains oxygen, which is a primary contaminant in metal deposition.

Without a high-vacuum pump, the evaporated metal would likely oxidize before forming a film, ruining the purity of the coating.

This is particularly critical for biomedical coatings or high-precision electronics where chemical purity is non-negotiable.

Impact on Coating Performance

Maximizing Hardness

The density and structure of a PVD coating are directly related to the energy with which the atoms strike the surface.

Collisions with gas molecules slow down the coating atoms, reducing their impact energy.

By eliminating these collisions, high-vacuum pumps ensure the coating forms a dense, hard structure.

Ensuring Adhesion

Adhesion relies on a clean interface between the substrate and the coating.

If gas impurities are present, they can become trapped between the workpiece and the coating layers.

High vacuum levels prevent this interference, allowing the coating to bond effectively to the workpiece lattice.

Understanding the Trade-offs

Zero Tolerance for Leaks

The necessity of these pumps introduces a strict "pass/fail" dynamic to the system.

Because the process relies on such deep vacuum ($10^{-5}$ to $10^{-6}$ torr), even microscopic leaks or pump inefficiencies will result in immediate process failure.

Operational Complexity

Diffusion and turbomolecular pumps add a layer of complexity compared to simple mechanical pumping.

They require specific operating sequences (such as backing pumps) to function correctly without damaging themselves.

However, this complexity is the unavoidable cost of achieving professional-grade PVD results.

Making the Right Choice for Your Goal

While you cannot avoid using a high-vacuum pump in PVD, understanding your specific needs clarifies their importance:

- If your primary focus is Durability: These pumps are essential to prevent gas collisions that soften the coating and reduce adhesion.

- If your primary focus is Chemical Purity: These pumps are critical for removing reactive elements like oxygen that would otherwise contaminate the film's stoichiometry.

Ultimately, the high-vacuum pump is not just an accessory; it is the component that transforms a PVD system from a simple evaporation chamber into a precision manufacturing tool.

Summary Table:

| Feature | Impact of High Vacuum (10⁻⁵ to 10⁻⁶ torr) | Consequence of Poor Vacuum |

|---|---|---|

| Mean Free Path | Maximized; atoms travel in straight lines | Collisions cause scattering and uneven coating |

| Stoichiometry | Precise chemical balance and purity | Impurities react with metal atoms unpredictably |

| Oxidation | Prevented; eliminates residual oxygen | Ruined purity and weakened film structure |

| Adhesion | Superior; clean interface for bonding | Trapped gases cause delamination and failure |

| Hardness | High; atoms strike with maximum energy | Slower impact energy leads to porous coatings |

Elevate Your PVD Coating Precision with KINTEK

Don't let residual gases compromise your coating integrity. At KINTEK, we specialize in providing high-performance high-temperature and vacuum solutions tailored for advanced material research and industrial manufacturing. Backed by expert R&D and manufacturing, we offer a comprehensive range of customizable Vacuum, CVD, and PVD-compatible systems designed to meet your unique thin-film requirements.

Ready to achieve superior hardness and chemical purity in your deposition process?

Contact Our Experts Today to discover how our high-vacuum technology can optimize your lab's efficiency and results.

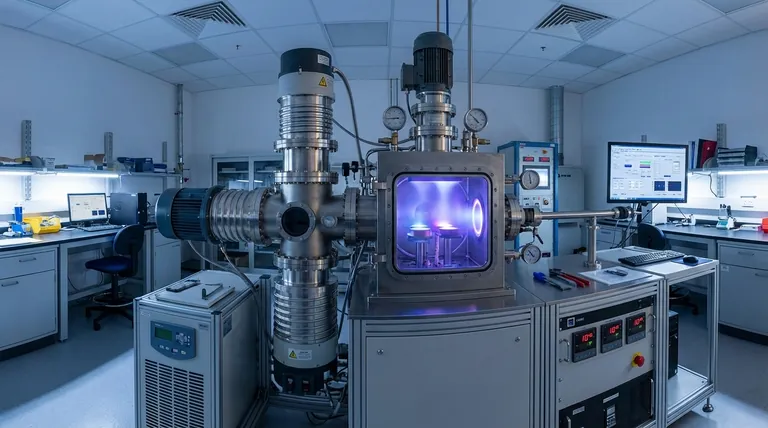

Visual Guide

References

- André Paulo Tschiptschin. PROCESSOS SOB VÁCUO USADOS PARA TRATAMENTOS TÉRMICOS E DE SUPERFÍCIE DE AÇOS E LIGAS ESPECIAIS. DOI: 10.17563/rbav.v43i1.1262

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How do quartz tube dimensions influence MoS2 CVD synthesis? Optimize Flow for High-Quality Monolayers

- What is the function of methane as a reaction gas source in CVD for BN@PyC aerogels? Master Material Rigidity

- What role does diluted silane (SiH4) gas play in beta-gallium oxide growth? Master Precise N-Type Doping

- What is Laser Chemical Vapor Deposition (LCVD)? Precision Micro-Scale 3D Printing for Thin Films

- How do IoT gas sensors and Autoencoders contribute to CVD furnace safety? Enhance Pipeline Integrity and Monitoring

- Why use Argon and Hydrogen for MnS Nanosheet CVD? Achieve High-Purity Synthesis Results

- What advanced materials and applications utilize CVD in electronics? Unlock Next-Gen Electronics with Precision CVD

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition