In high-temperature experiments, corundum crucibles and boats are used as containers for metallic magnesium evaporation because they possess two critical properties: an extremely high melting point and exceptional chemical stability. These characteristics ensure the corundum does not melt, deform, or react with the highly reactive molten magnesium, thus preventing sample contamination.

The core challenge in high-temperature experiments with reactive metals is finding a container that is completely non-interactive. Corundum (high-purity alumina) is chosen because it acts as a truly inert vessel, guaranteeing the purity of the final evaporated product.

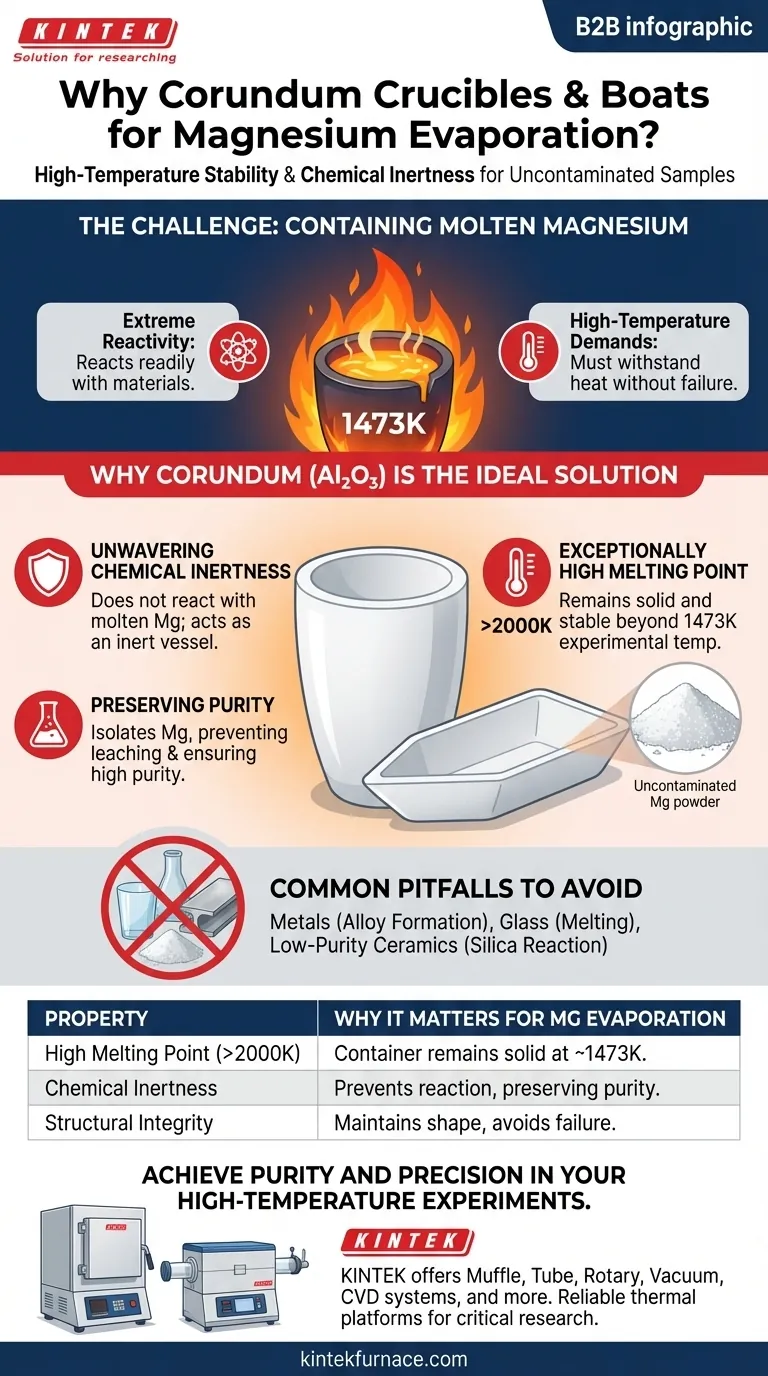

The Challenge of Containing Molten Magnesium

To understand the choice of corundum, we must first appreciate the extreme conditions of the experiment. Handling molten magnesium at high temperatures presents significant material science challenges.

Extreme Chemical Reactivity

At temperatures reaching 1473K, liquid magnesium becomes exceptionally reactive. It will readily react with many common materials, forming alloys, oxides, or other compounds that would compromise the experiment's integrity.

High-Temperature Demands

The container must withstand these high temperatures without melting, cracking, or losing its structural shape. Any degradation of the container would not only ruin the experiment but could also pose a safety risk.

Why Corundum is the Ideal Solution

Corundum, a specific form of high-purity aluminum oxide (Al₂O₃), is uniquely suited to overcome these challenges. Its properties make it the standard choice for this application.

Unwavering Chemical Inertness

High-purity alumina demonstrates remarkable chemical stability. It does not react with molten magnesium, even under the high-vacuum or inert argon atmospheres required for these experiments. This inertness is the primary reason for its selection.

Exceptionally High Melting Point

The melting point of corundum is well above 2000K, far exceeding the experimental temperature of 1473K. This thermal stability ensures the crucible or boat remains a solid, stable container throughout the entire evaporation process.

The Goal: Preserving Purity

By being both thermally stable and chemically inert, the corundum container effectively isolates the molten magnesium. This prevents any elements from the crucible from leaching into the sample, ensuring the high purity of the evaporated and subsequently condensed magnesium powder.

Common Pitfalls to Avoid

Choosing the wrong container material is a critical experimental failure. The properties of corundum highlight why other common lab materials are unsuitable for this specific task.

Why Metals and Glass Fail

A metal container would likely form an alloy with the molten magnesium, contaminating the sample. Standard laboratory glassware, like borosilicate, would simply melt or react at these temperatures.

The Importance of High Purity

It is crucial to use high-purity corundum or alumina. Lower-grade ceramics may contain silica or other impurities that could react with the highly aggressive liquid magnesium, defeating the purpose of using a ceramic container.

Making the Right Choice for Your Experiment

Your choice of container material is fundamental to the success and validity of any high-temperature metallurgical experiment.

- If your primary focus is sample purity: Corundum is the superior choice because its chemical inertness is the best defense against contamination from the container.

- If your primary focus is extreme temperature stability: Corundum's high melting point guarantees structural integrity far beyond the temperatures required for magnesium evaporation.

- If your primary focus is preventing unwanted reactions: The excellent corrosion resistance of corundum makes it the ideal inert vessel for holding chemically aggressive molten metals.

Ultimately, selecting the correct material is the first step toward achieving reliable and accurate experimental results.

Summary Table:

| Property | Why It Matters for Magnesium Evaporation |

|---|---|

| High Melting Point (>2000K) | Container remains solid and stable at magnesium's evaporation temperature (~1473K). |

| Chemical Inertness | Prevents reaction with highly aggressive molten magnesium, preserving sample purity. |

| Structural Integrity | Maintains shape under high heat, avoiding deformation and potential experimental failure. |

Achieve Purity and Precision in Your High-Temperature Experiments

Just as a corundum crucible is essential for uncontaminated magnesium evaporation, the right furnace is critical for your lab's success. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Let us provide the reliable thermal platform for your critical research. Contact our experts today to discuss how our solutions can enhance your results.

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab

- Why are tubular furnaces important in material testing and research? Unlock Precision for Advanced Materials Development

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment