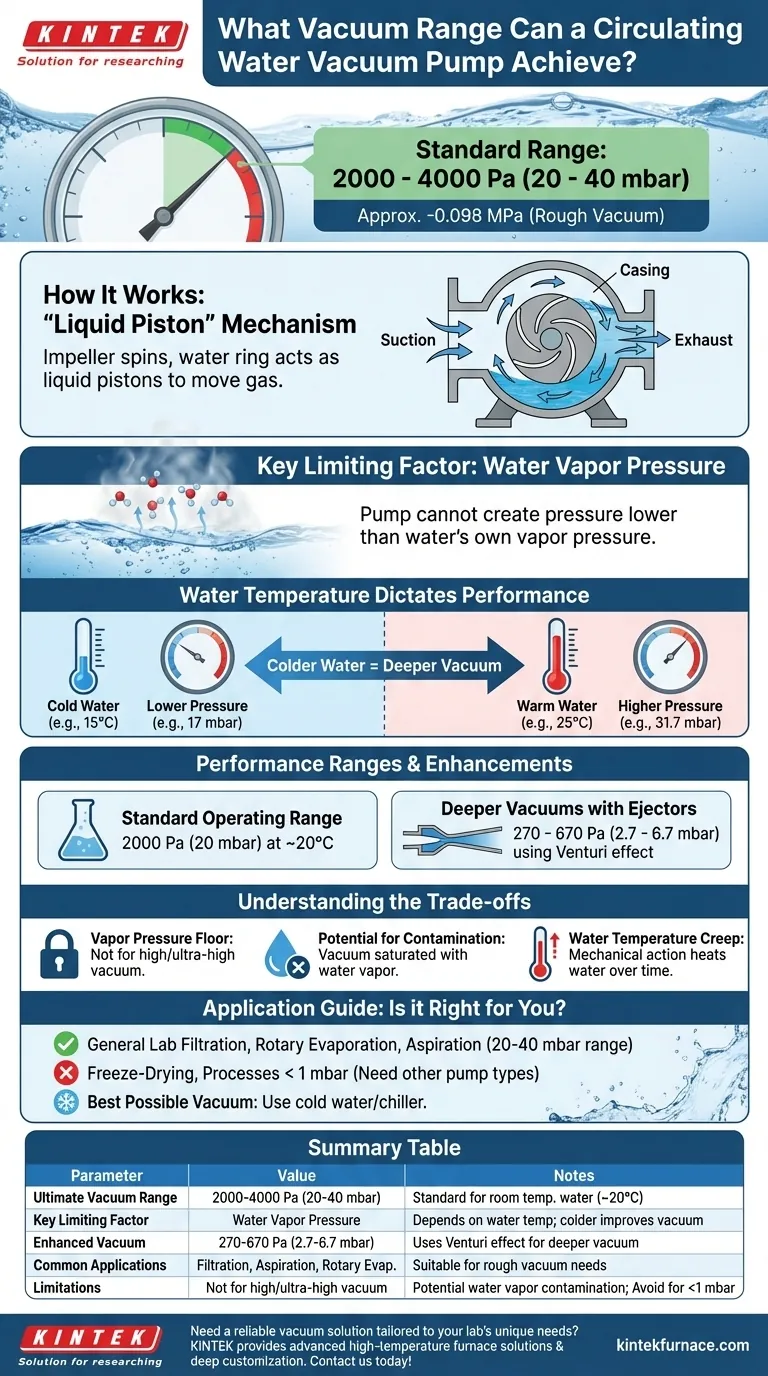

In short, a standard circulating water vacuum pump achieves an ultimate vacuum level in the range of 2000 to 4000 Pascals (Pa). This is equivalent to 20 to 40 millibars (mbar) or a gauge pressure reading of approximately -0.098 Megapascals (MPa). This level is considered a rough or low vacuum, making it ideal for many common laboratory applications like filtration, aspiration, and rotary evaporation.

While the technical specification is typically around 20-40 mbar, the true performance of a water vacuum pump is fundamentally limited by the vapor pressure of the water it uses. Understanding this principle is the key to determining if it meets your application's requirements.

How a Water Pump Creates a Vacuum

A circulating water vacuum pump, also known as a water ring pump, is a simple and robust device. It uses water as its working fluid to remove gas molecules from a sealed volume.

The "Liquid Piston" Mechanism

Inside the pump, an impeller spins off-center within a casing. This creates a ring of water held against the outer wall by centrifugal force.

Because the impeller is eccentric, the space between its blades and the water ring continuously expands and contracts. The expanding space draws gas in (suction), and the contracting space compresses and expels the gas (exhaust). This action effectively uses the water ring as a series of liquid pistons.

The Key Limiting Factor: Water Vapor Pressure

The pump's ultimate vacuum is not limited by its mechanical design, but by the physics of water itself. As the pressure in the system drops, the water in the pump begins to evaporate (or boil at a lower temperature).

This water vapor fills the vacuum space. The pump cannot create a pressure lower than the vapor pressure of the water it is using, because the water itself will always generate that much pressure.

How Water Temperature Dictates Performance

The vapor pressure of water is directly dependent on its temperature. Colder water has a lower vapor pressure, which results in a deeper (lower pressure) vacuum.

For example, at 25°C (77°F), water's vapor pressure is about 31.7 mbar. At 15°C (59°F), it drops to 17 mbar. This means simply using colder water can significantly improve your pump's performance.

Performance Ranges and Enhancements

Knowing the underlying principle helps you understand the practical specifications you will encounter.

The Standard Operating Range

Most specifications list a vacuum of 2000 Pa (20 mbar). This assumes the circulating water is at or around room temperature (approx. 20°C / 68°F), where water's vapor pressure is 23.4 mbar. This is the realistic, everyday performance you should expect.

Flow Rate vs. Ultimate Vacuum

It's important to distinguish between flow rate (e.g., 80 L/min) and ultimate vacuum. Flow rate measures how fast the pump removes air, while ultimate vacuum measures how much air it can ultimately remove. A high flow rate does not guarantee a deeper vacuum.

Reaching Deeper Vacuums with Ejectors

Some systems can be equipped with a series atmospheric ejector. This device uses the Venturi effect to create an additional low-pressure stage, allowing the system to reach a deeper vacuum of 270 to 670 Pa (2.7 to 6.7 mbar), pushing past the normal water vapor pressure limit.

Understanding the Trade-offs

Water vacuum pumps are popular for a reason, but it's critical to know their limitations.

The Vapor Pressure Floor

This is the primary trade-off. These pumps are physically incapable of achieving high or ultra-high vacuum levels required for applications like mass spectrometry or surface science.

Potential for Contamination

The vacuum created is not "clean." It is saturated with water vapor, which can contaminate sensitive samples or interfere with certain chemical reactions.

Water Temperature Creep

In a closed-loop system without a cooling unit (chiller), the pump's mechanical action will heat the water over time. As the water warms up, its vapor pressure increases, and the vacuum performance will steadily get worse.

Is a Water Pump Right for Your Goal?

Use this guide to determine if a circulating water vacuum pump fits your needs.

- If your primary focus is general lab filtration, rotary evaporation, or aspiration: A water pump is an excellent, robust, and cost-effective choice, as these processes operate well within the 20-40 mbar range.

- If your primary focus is freeze-drying (lyophilization) or processes requiring vacuums below 1 mbar: You will need a different type of pump, such as a two-stage rotary vane pump or a dry scroll pump.

- If your primary focus is achieving the best possible vacuum from your water pump: Use cold, fresh water or connect the pump to a refrigerated circulator to keep the water temperature consistently low.

By understanding that performance is tied directly to water temperature, you can effectively manage and optimize your vacuum process.

Summary Table:

| Parameter | Value | Notes |

|---|---|---|

| Ultimate Vacuum Range | 2000-4000 Pa (20-40 mbar) | Standard for room temperature water (~20°C) |

| Key Limiting Factor | Water Vapor Pressure | Depends on water temperature; colder water improves vacuum |

| Enhanced Vacuum with Ejector | 270-670 Pa (2.7-6.7 mbar) | Uses Venturi effect for deeper vacuum |

| Common Applications | Filtration, Aspiration, Rotary Evaporation | Suitable for rough vacuum needs |

| Limitations | Not for high/ultra-high vacuum, potential water vapor contamination | Avoid for processes requiring <1 mbar |

Need a reliable vacuum solution tailored to your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your experimental requirements, whether you're optimizing vacuum processes or handling complex thermal applications. Contact us today to discuss how our expertise can enhance your laboratory's efficiency and results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How is a vacuum pump system used to simulate high-altitude gasification conditions? Replicate 3000m Pressure Levels

- What is the necessity of an observation window in a magnesium combustion chamber? Elevate Your Visual Data Analysis

- What are the advantages of using a platinum crucible? Essential for High-Purity Alumino-Borosilicate Glass Synthesis

- Why are high-purity quartz tubes and quartz boats preferred for plastic pyrolysis? Ensure Precise, Pure Results

- Why is selecting the right laboratory furnace important for ceramic sintering? Ensure Precise Control for Superior Ceramic Properties

- Why is it necessary to use alumina or ceramic crucibles during the high-temperature evaporation of magnesium? Ensure Purity and Process Integrity

- What are the preparation steps for a water circulating vacuum pump? Ensure Optimal Performance and Longevity

- Why is laboratory heating equipment critical for photothermal actuators? Master Structural Curing & Precision Thermal Control