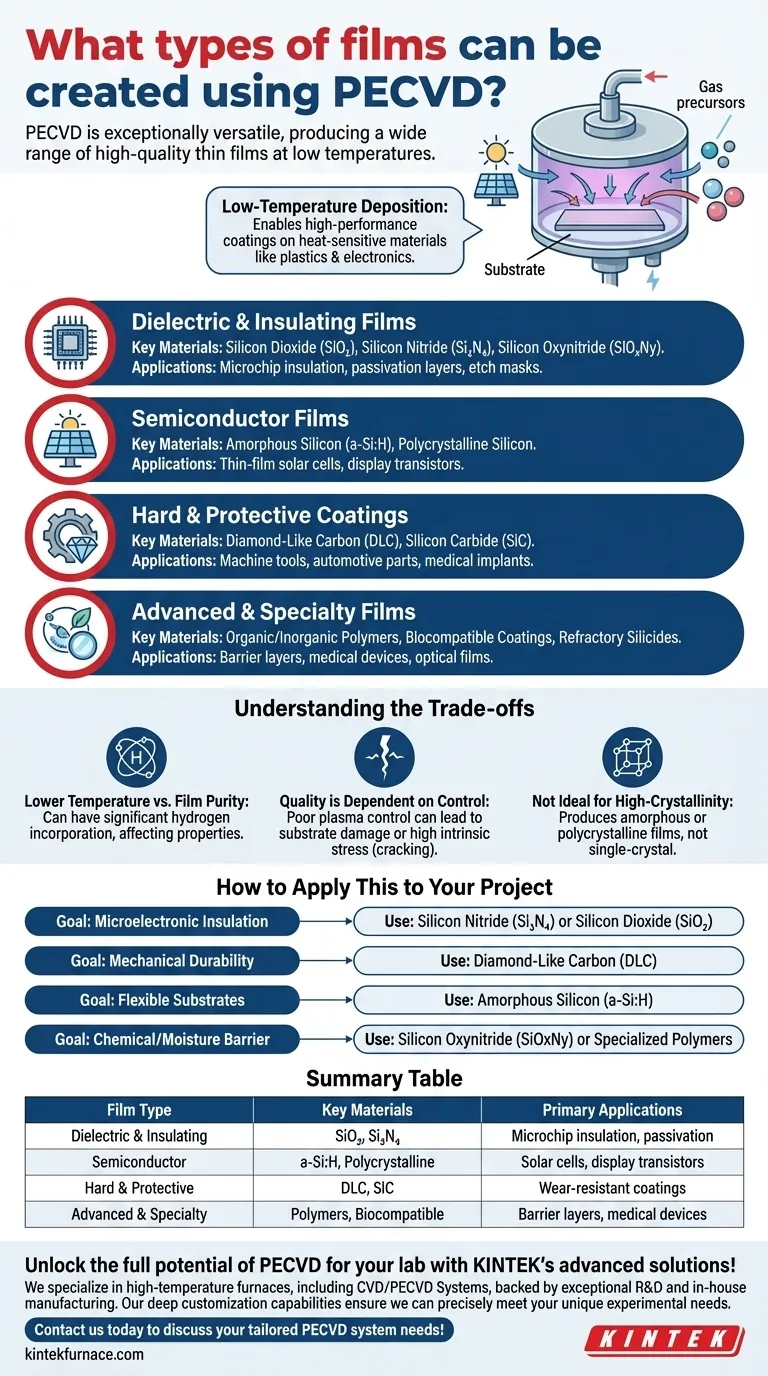

In short, PECVD is exceptionally versatile. It can be used to create a wide range of thin films, most notably dielectric insulators like silicon dioxide and silicon nitride, semiconductor films like amorphous silicon, and hard protective coatings such as diamond-like carbon. The process is valued for its ability to produce high-quality, uniform, and durable films on a variety of substrates.

The true power of PECVD is not just the variety of films it can create, but its ability to deposit them at low temperatures. This opens the door to applying high-performance coatings on materials, like plastics or pre-fabricated electronics, that cannot withstand the high heat of traditional deposition methods.

The Core Material Groups Deposited by PECVD

Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses plasma to energize precursor gases, allowing film deposition to occur at significantly lower temperatures than conventional Chemical Vapor Deposition (CVD). This fundamental advantage enables its broad material capabilities.

Dielectric and Insulating Films

This is the most common application of PECVD, particularly in the semiconductor industry. These films electrically isolate different components on a microchip.

The primary materials are silicon dioxide (SiO₂) and silicon nitride (Si₃N₄). Silicon oxynitride (SiOxNy) is also used to tune properties between the two. These films serve as insulators, passivation layers to protect against moisture and contaminants, and as etch masks.

Semiconductor Films

PECVD is capable of depositing essential semiconductor materials. These films are the building blocks for transistors and solar cells.

The most prominent example is amorphous silicon (a-Si:H), which is critical for thin-film solar cells and the transistors in large-area displays. The process can also be tuned to create polycrystalline silicon or even some forms of epitaxial silicon.

Hard and Protective Coatings

These films are engineered for mechanical durability, wear resistance, and chemical protection.

Diamond-Like Carbon (DLC) is a key material deposited via PECVD. It creates an extremely hard, low-friction surface used on machine tools, automotive parts, and medical implants. Silicon carbide (SiC) is another hard material deposited for similar protective purposes.

Advanced and Specialty Films

The flexibility of PECVD extends to more specialized materials for a variety of advanced applications.

This includes organic and inorganic polymers for creating barrier layers in food packaging, biocompatible coatings for medical devices, and even certain refractory metals and their silicides. This versatility allows for creating films with unique properties like high corrosion resistance or specific optical transparency.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. Understanding its limitations is key to using it effectively.

Lower Temperature vs. Film Purity

The use of plasma and hydrogen-rich precursor gases means that films, such as amorphous silicon (a-Si:H), often have significant hydrogen incorporation. While sometimes beneficial, this can be an unwanted impurity that affects electrical or optical properties.

Quality is Dependent on Control

The plasma environment involves energetic ion bombardment on the substrate surface. While this can improve film density and adhesion, poor control can lead to substrate damage or high intrinsic film stress, which may cause cracking or delamination over time.

Not Ideal for High-Crystallinity Films

For applications requiring near-perfect single-crystal films, such as high-performance microprocessors, other techniques like Molecular Beam Epitaxy (MBE) or high-temperature CVD are superior. PECVD typically produces amorphous or polycrystalline films.

How to Apply This to Your Project

Your choice of film is dictated entirely by your end goal. The versatility of PECVD allows you to select a material based on the specific function you need to engineer.

- If your primary focus is microelectronic insulation: Use silicon nitride (Si₃N₄) for its excellent barrier properties or silicon dioxide (SiO₂) for general-purpose insulation.

- If your primary focus is mechanical durability and wear resistance: Use Diamond-Like Carbon (DLC) for its extreme hardness and low friction.

- If your primary focus is fabricating devices on flexible or heat-sensitive substrates: Use amorphous silicon (a-Si:H) for applications like flexible displays or solar cells.

- If your primary focus is creating a chemical or moisture barrier: Explore silicon oxynitride (SiOxNy) or specialized polymers for applications from protective coatings to food packaging.

Ultimately, PECVD empowers you to engineer surfaces by depositing a functional film tailored to solve your specific technical challenge.

Summary Table:

| Film Type | Key Materials | Primary Applications |

|---|---|---|

| Dielectric & Insulating | Silicon Dioxide (SiO₂), Silicon Nitride (Si₃N₄) | Microchip insulation, passivation layers |

| Semiconductor | Amorphous Silicon (a-Si:H), Polycrystalline Silicon | Thin-film solar cells, transistors in displays |

| Hard & Protective | Diamond-Like Carbon (DLC), Silicon Carbide (SiC) | Wear-resistant coatings for tools, automotive parts |

| Advanced & Specialty | Organic/Inorganic Polymers, Biocompatible Coatings | Barrier layers, medical devices, optical films |

Unlock the full potential of PECVD for your lab with KINTEK's advanced solutions! We specialize in high-temperature furnaces, including CVD/PECVD Systems, backed by exceptional R&D and in-house manufacturing. Our deep customization capabilities ensure we can precisely meet your unique experimental needs, whether you're working on microelectronics, solar cells, or protective coatings. Contact us today to discuss how our tailored PECVD systems can enhance your research and development outcomes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition