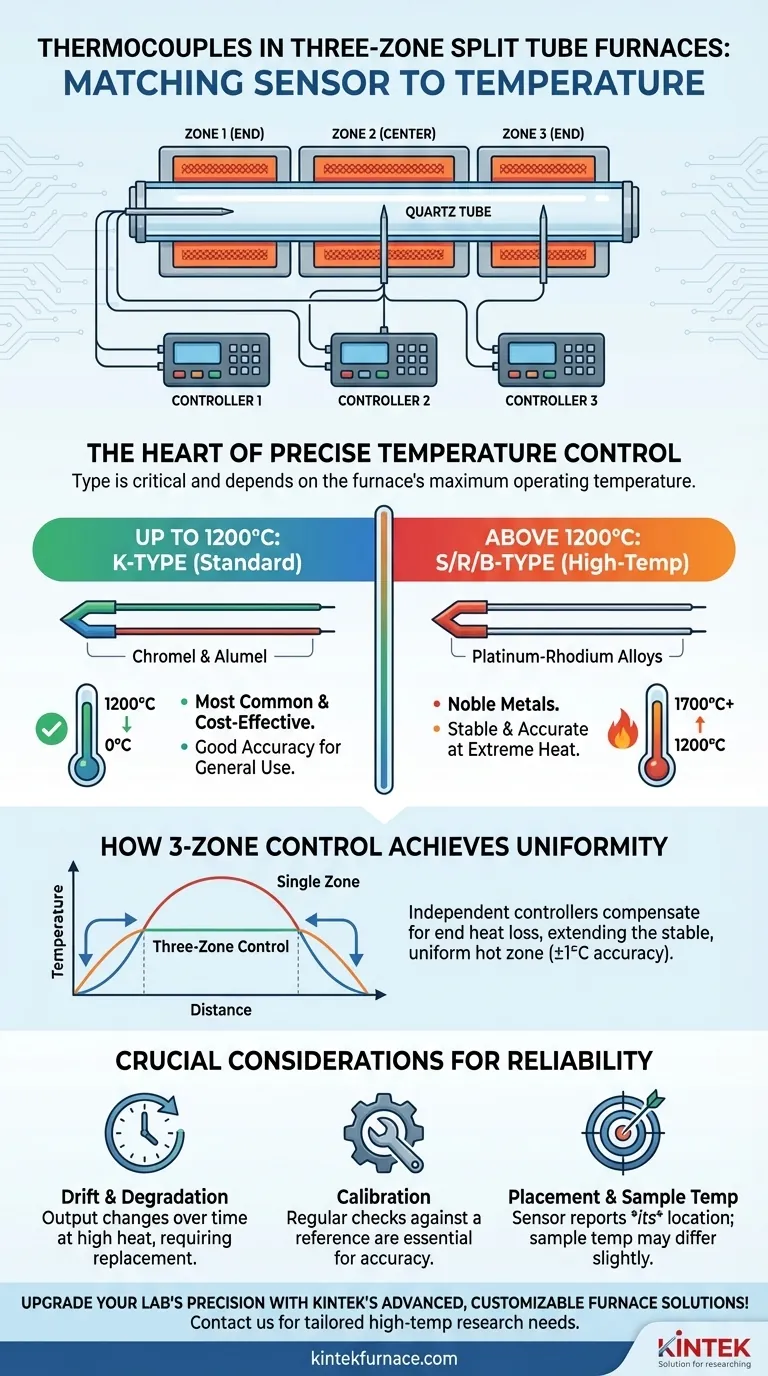

In most standard configurations, a three-zone split tube furnace operating up to 1200°C will use a K-type thermocouple for temperature measurement and control. However, the specific type is critically dependent on the furnace's maximum operating temperature, with different materials being required for higher-temperature applications.

The thermocouple type is not a universal constant but is carefully matched to the furnace's temperature capability. While K-type is a common workhorse for systems up to 1200°C, furnaces designed for 1400°C, 1700°C, or higher require platinum-based thermocouples like S-type, R-type, or B-type.

Why the Thermocouple Is the Heart of Temperature Control

The thermocouple is the primary sensor that feeds information to the furnace's controller. Its accuracy, stability, and temperature range fundamentally dictate the performance and limitations of the entire system.

The Role of the Thermocouple

A thermocouple is a sensor made of two dissimilar metal wires joined at one end. When this junction is heated, it produces a small, predictable voltage that corresponds directly to the temperature, allowing for precise measurement.

Matching the Sensor to the System's Heat

The choice of thermocouple is a direct function of the furnace's maximum temperature.

-

K-Type (up to ~1200°C): Made from Chromel and Alumel, this is the most common general-purpose thermocouple. It offers good accuracy and a wide operating range at a reasonable cost, making it ideal for many standard laboratory furnaces.

-

S-Type, R-Type, and B-Type (for >1200°C): For furnaces operating at higher temperatures like 1400°C or 1700°C, a K-type is unsuitable. These systems require noble metal thermocouples, typically platinum-rhodium alloys (S, R, or B-types), which remain stable and accurate at extreme temperatures.

How Three-Zone Control Achieves Uniformity

The "three-zone" design is specifically engineered to create a longer, more uniform temperature profile than a single-zone furnace can provide. This is achieved by using independent thermocouples and controllers.

Independent Zones for Precise Control

A three-zone furnace has three distinct heating elements arranged end-to-end. Each of these zones has its own dedicated thermocouple to measure its local temperature.

Creating a Uniform Hot Zone

The controllers for the two end zones are programmed to match the temperature of the central zone. This active management compensates for heat loss at the ends of the tube, effectively extending the length of the stable, uniform hot zone in the middle.

The Impact on Temperature Accuracy

This multi-point measurement and control is what allows these furnaces to achieve high accuracy, often cited as ±1°C. Without a dedicated thermocouple in each zone, it would be impossible to counteract thermal gradients and ensure uniformity across the furnace's length.

Understanding the Trade-offs and Limitations

While effective, thermocouple-based systems have inherent characteristics that you must be aware of for reliable and repeatable results.

Thermocouple Drift and Degradation

Over time, especially when held at high temperatures, all thermocouples can experience "drift," where their voltage output changes for a given temperature. This means they become less accurate. This is more pronounced in base-metal thermocouples like K-type.

Calibration and Replacement

To maintain accuracy, thermocouples require periodic calibration checks against a known reference. If drift becomes significant, the thermocouple must be replaced. This is a standard maintenance procedure for high-temperature equipment.

Placement and Sample Temperature

It is crucial to remember that the thermocouple reports the temperature at its specific location. The temperature of your actual sample may differ slightly due to its position, size, and thermal mass.

Making the Right Choice for Your Goal

When evaluating a three-zone furnace, match its components to your specific experimental needs.

- If your primary focus is general use up to 1200°C: A furnace specified with K-type thermocouples is a reliable and cost-effective solution.

- If your primary focus is high-temperature synthesis (e.g., 1400°C to 1700°C): You must confirm the furnace is equipped with the appropriate platinum-based thermocouple (S, R, or B-type) for stability and accuracy.

- If your primary focus is maximum temperature uniformity: Ensure the system uses three independent thermocouples and controllers to actively manage the temperature profile across the entire heated length.

Understanding how the thermocouple type aligns with the furnace's temperature range empowers you to select the right tool for your work.

Summary Table:

| Thermocouple Type | Max Temperature | Common Use Cases | Key Characteristics |

|---|---|---|---|

| K-Type | Up to 1200°C | Standard lab furnaces | Cost-effective, good accuracy, wide range |

| S/R/B-Type | Above 1200°C | High-temp synthesis | Platinum-based, stable at extreme temps |

Upgrade your lab's precision with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior temperature control and uniformity. Contact us today to discuss how our tailored solutions can enhance your research efficiency and accuracy!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

People Also Ask

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What are the advantages of using molybdenum-disilicide heating elements for aluminum alloy processing? (Rapid Heating Guide)

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- What are the primary applications of MoSi2 heating elements in research? Achieve Reliable High-Temp Control for Material Synthesis

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence