In industrial heat treatment, continuous furnaces are unequivocally favored for high-volume production of standardized or similar parts. Their design is optimized for manufacturing environments where a consistent, uninterrupted flow of material needs to be processed with maximum efficiency and uniformity, making them a cornerstone of mass production.

The core advantage of a continuous furnace isn't just its capacity for high volume; it's the profound economic and operational efficiency gained from uninterrupted processing. By eliminating the start-stop cycles of batch furnaces, they minimize costly downtime and dramatically reduce the per-unit cost of production.

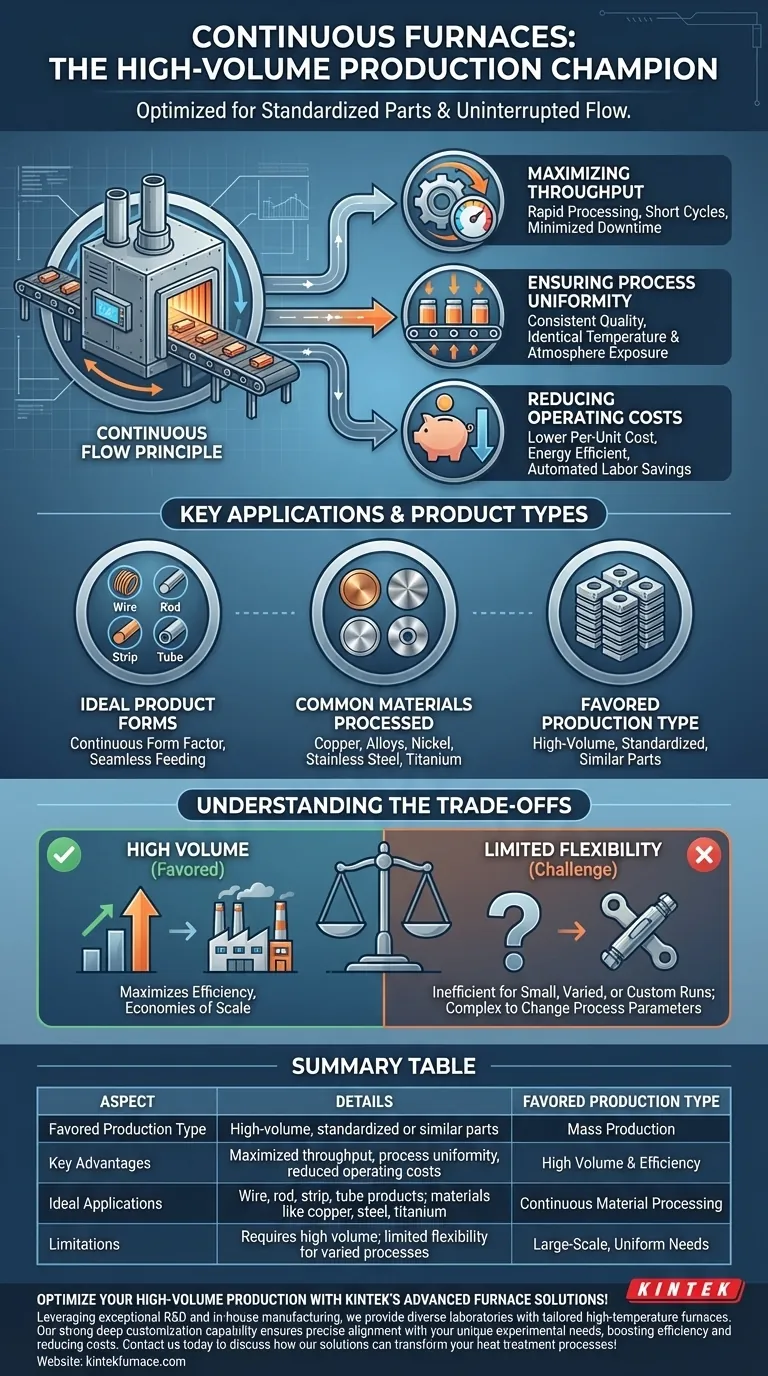

The Principle of Continuous Flow

The fundamental value of a continuous furnace lies in its name—it operates continuously. This design philosophy creates a highly efficient and predictable production environment, starkly different from the cyclical nature of batch processing.

Maximizing Throughput

Continuous furnaces are engineered for rapid processing. Parts move through various heating and cooling zones without interruption, which enables short production cycles and maximizes the number of units processed per hour.

This constant operation minimizes downtime associated with loading, unloading, and reheating, which are inherent bottlenecks in batch furnace systems.

Ensuring Process Uniformity

Because these furnaces are set up for a specific, repetitive process, they deliver exceptional consistency. Every part is exposed to the exact same temperature profile and atmospheric conditions as it travels through the furnace.

This uniformity is critical for quality control in large-scale manufacturing, where even minor deviations can affect thousands of parts.

Reducing Operating Costs

While the initial investment is higher, the per-unit operating cost is significantly lower in a high-volume setting. Continuous operation is more energy-efficient than repeatedly heating and cooling a batch furnace.

Furthermore, the automated nature of continuous systems reduces the need for manual labor, leading to substantial long-term cost savings.

Key Applications and Product Types

Continuous furnaces are not a one-size-fits-all solution. They excel when processing specific types of products at a massive scale.

Ideal Product Forms

They are perfectly suited for processing products that have a continuous form factor themselves. This includes industrial staples such as wire, rod, strip, and tube products.

The furnace allows these long materials to be fed through seamlessly, undergoing processes like annealing or tempering along their entire length.

Common Materials Processed

These furnaces are versatile in the materials they can handle. They are commonly used for heat-treating copper, copper alloys, nickel, stainless steel, titanium, and other high-performance metals that are foundational to modern industry.

Understanding the Trade-offs

The efficiency of a continuous furnace comes with specific operational requirements and limitations. Understanding these trade-offs is crucial for making an informed investment.

The Need for High Volume

The primary limitation is their inefficiency for small or varied production runs. The economic benefits only materialize when the furnace is run at or near full capacity for extended periods.

For low-volume or custom jobs, the time and energy required to bring the furnace to a stable operating temperature make it highly uneconomical.

Limited Flexibility

A continuous furnace is typically optimized for a single thermal process. Changing the temperature profile, cycle time, or atmospheric conditions is a complex and time-consuming task.

This lack of flexibility makes them unsuitable for job shops or R&D environments that require frequent changes to process parameters for different products.

Making the Right Choice for Your Goal

Choosing between a continuous and a batch furnace is a strategic decision that must align with your production volume and product mix.

- If your primary focus is maximizing throughput for a single, high-volume product: A continuous furnace is the unmatched solution for its efficiency and low per-unit operating cost.

- If your primary focus is processing diverse, low-volume batches with varying requirements: A batch furnace offers the necessary flexibility and is far more economical for non-continuous operation.

- If your primary focus is long-term cost reduction at a massive scale: The significant savings in energy and labor from a continuous furnace will justify the higher initial capital investment.

Ultimately, the right furnace aligns your heat treatment capability directly with your business model and production volume.

Summary Table:

| Aspect | Details |

|---|---|

| Favored Production Type | High-volume, standardized or similar parts |

| Key Advantages | Maximized throughput, process uniformity, reduced operating costs |

| Ideal Applications | Wire, rod, strip, tube products; materials like copper, steel, titanium |

| Limitations | Requires high volume; limited flexibility for varied processes |

Optimize your high-volume production with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and reducing costs. Contact us today to discuss how our solutions can transform your heat treatment processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure