In short, a standard electric muffle furnace typically operates in a range of 300°C to 1200°C (572°F to 2192°F). However, this is only part of the story, as specialized models built for advanced applications can reliably reach 1600°C, 1800°C, or even higher by using different materials in their construction.

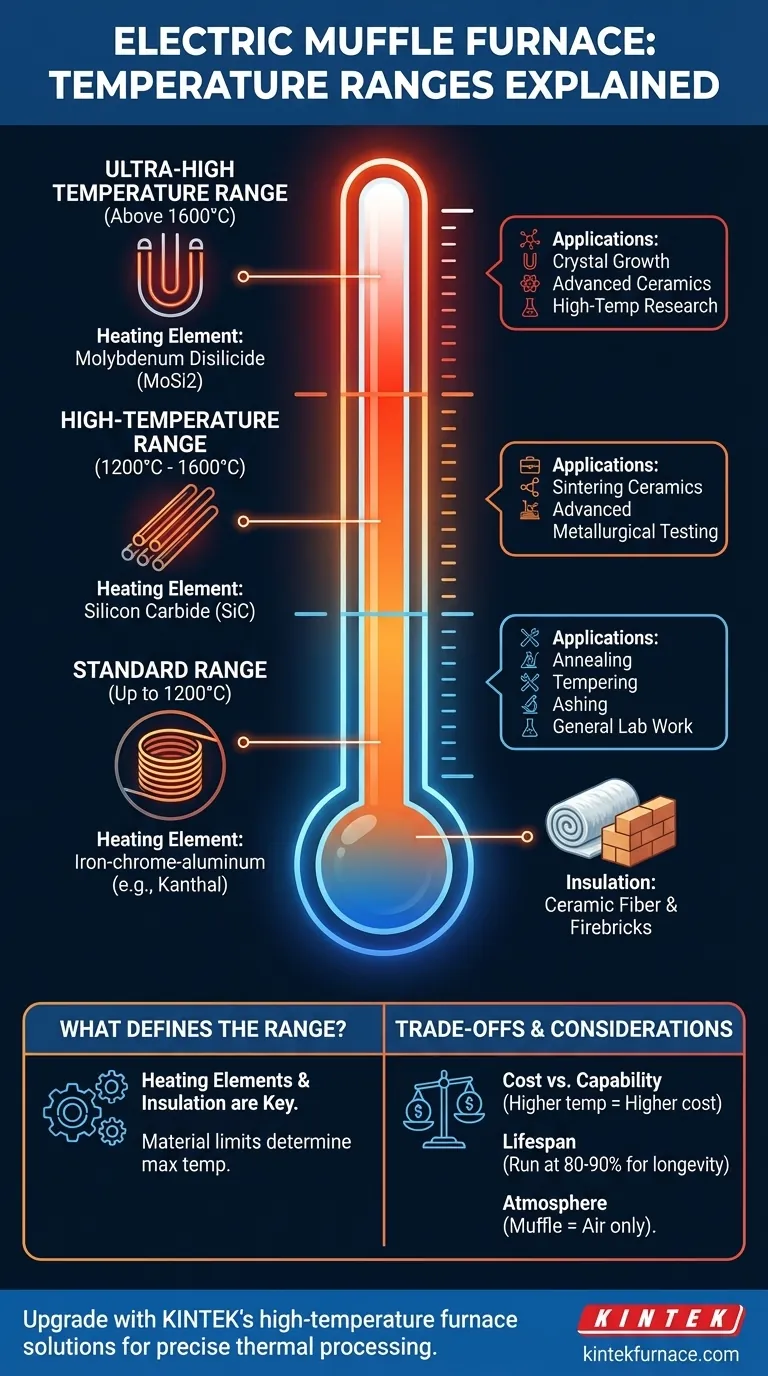

The maximum temperature of an electric muffle furnace is not a single number but a specification tied directly to its intended purpose. The choice of heating elements and insulation materials dictates its thermal capability, creating distinct tiers of performance for different scientific and industrial tasks.

What Defines a Furnace's Temperature Range?

A muffle furnace is a system where the heating elements and the internal chamber must work in concert. The maximum temperature is determined by the material limits of these core components, which are chosen based on the furnace's intended applications.

The Role of Heating Elements

The heating elements are the heart of the furnace, and their material composition is the primary factor limiting the maximum temperature.

- Up to ~1200°C: Most standard furnaces use iron-chrome-aluminum alloy wire (like Kanthal). These are robust and cost-effective for a wide range of common heat-treating and laboratory processes.

- Up to ~1600°C: Higher-temperature models often use Silicon Carbide (SiC) rods. These elements can operate at much higher temperatures but are more brittle and expensive.

- Up to ~1800°C and beyond: The highest-performance furnaces utilize Molybdenum Disilicide (MoSi2) elements. They are the most expensive but are required for advanced ceramics, melting certain alloys, and high-temperature material science research.

Insulation and Chamber Materials

The furnace chamber must contain extreme heat efficiently. Poor insulation leads to heat loss, inaccurate temperatures, and potential damage to the furnace.

High-quality refractory ceramic fiber and firebricks are used to line the chamber, ensuring thermal stability and protecting the outer shell. The higher the target temperature, the more advanced and robust the insulation package must be.

Intended Application as the Driving Factor

Ultimately, the temperature range is a direct reflection of the furnace's designed purpose. A simple ashing furnace for a biology lab has different material requirements than a furnace used for sintering advanced technical ceramics. Manufacturers select the appropriate heating elements and insulation to meet a specific market need reliably and cost-effectively.

Common Temperature Tiers and Their Uses

Understanding these tiers helps you match the equipment to your specific process.

Standard Range (Up to 1200°C)

This is the workhorse range for most applications. Furnaces in this class are suitable for processes like annealing, tempering, hardening common steels, ashing organic materials, and general-purpose thermal testing.

High-Temperature Range (1200°C to 1600°C)

This tier is necessary for more demanding applications. It's often used in materials science for sintering some ceramics, working with specific alloys, and conducting advanced metallurgical testing where higher thermal energy is required.

Ultra-High Temperature Range (Above 1600°C)

These are highly specialized instruments. Their applications include growing crystals, developing and testing advanced ceramics, melting high-temperature alloys, and fundamental materials research. These furnaces represent a significant investment and are used for tasks that are impossible in standard models.

Understanding the Trade-offs

Choosing a furnace based on maximum temperature alone can be a mistake. You must consider the associated costs and limitations.

Cost vs. Capability

There is a direct and steep correlation between maximum temperature and price. The specialized materials required for high-temperature elements (MoSi2) and advanced insulation are significantly more expensive than those used in standard 1200°C models.

Lifespan of Consumables

Heating elements are consumable parts with a finite lifespan. Consistently operating a furnace at its absolute maximum rated temperature will degrade the elements much faster than running it at 80-90% of its capacity. A furnace rated for 1200°C will have a much longer element life if typically used at 1000°C.

Atmosphere Control

A standard electric muffle furnace operates in an ambient air atmosphere. If your process is sensitive to oxygen (e.g., requires an inert gas like argon or a vacuum), a muffle furnace is the wrong tool. You would need a specialized tube furnace or vacuum furnace designed for atmosphere control.

Making the Right Choice for Your Goal

Select a furnace that comfortably exceeds your required process temperature without excessive overkill to ensure efficiency and longevity.

- If your primary focus is general laboratory work like ashing, drying, or basic annealing: A standard furnace reaching 1100°C or 1200°C is cost-effective and perfectly suitable.

- If your primary focus is heat-treating most tool steels: A furnace capable of reaching at least 1300°C provides the necessary range for hardening and tempering processes.

- If your primary focus is advanced materials science with ceramics or alloys: You will need a high-temperature model capable of reaching 1600°C to 1800°C, depending on your specific material requirements.

- If your primary focus is any process requiring an oxygen-free environment: A standard muffle furnace is unsuitable; you must specify a furnace designed for vacuum or inert gas atmospheres.

Ultimately, understanding your precise thermal processing needs is the key to selecting the right tool for the job.

Summary Table:

| Temperature Range | Common Heating Elements | Typical Applications |

|---|---|---|

| Up to 1200°C | Iron-chrome-aluminum alloy (e.g., Kanthal) | Annealing, tempering, ashing, general lab work |

| 1200°C to 1600°C | Silicon Carbide (SiC) | Sintering ceramics, advanced metallurgical testing |

| Above 1600°C | Molybdenum Disilicide (MoSi2) | Crystal growth, advanced ceramics, high-temperature research |

Upgrade your laboratory with KINTEK's high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with advanced options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and performance. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis