At its core, the stability of a dental sintering furnace is the single most important factor in producing high-quality dental restorations. This stability is achieved through precise and consistent control over temperature and atmosphere, which directly ensures that every crown, bridge, or veneer possesses uniform strength, accurate fit, and predictable longevity.

The term "stability" goes beyond simple machine reliability. It refers to the furnace's ability to perfectly and repeatedly execute a complex heating and cooling profile, guaranteeing that the final ceramic restoration is structurally sound, clinically accurate, and free of internal defects.

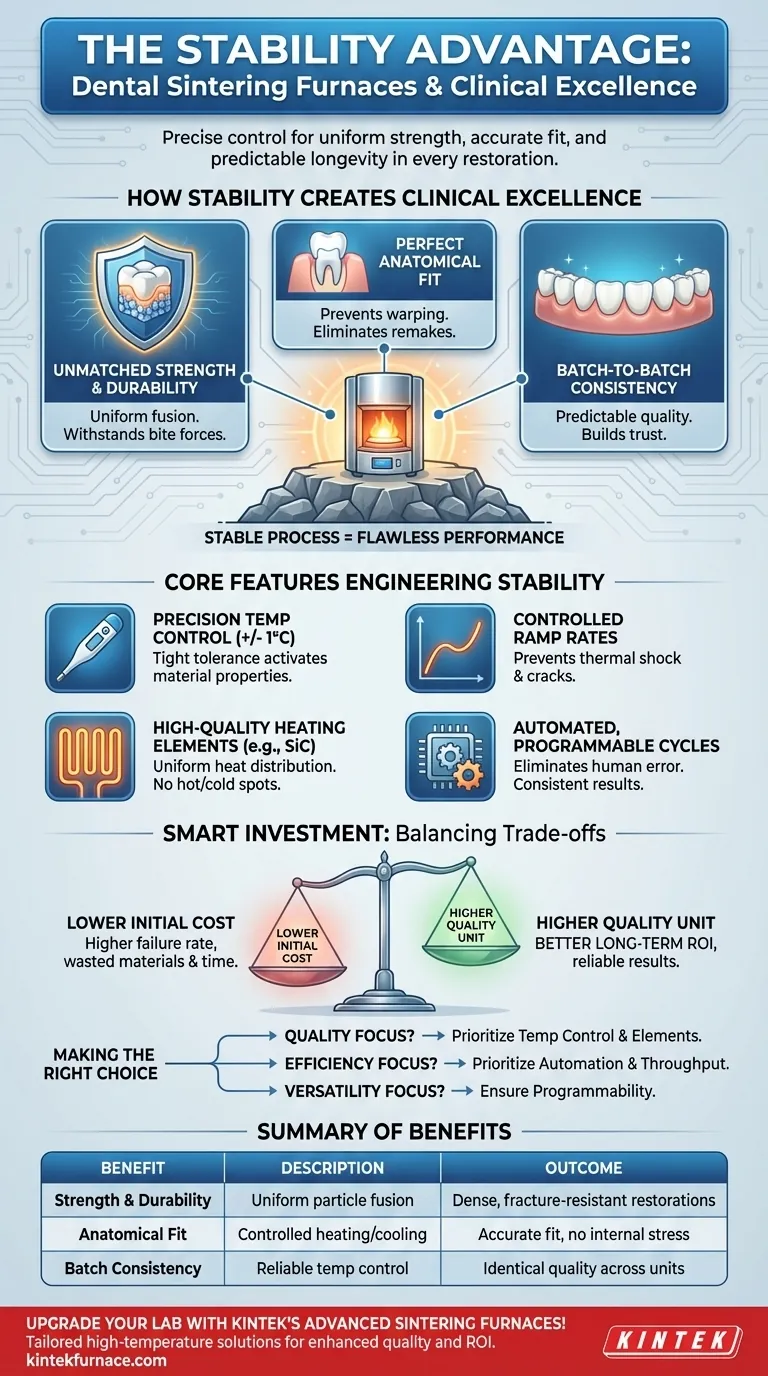

How Sintering Stability Creates Clinical Excellence

The primary goal of any dental lab is to produce restorations that perform flawlessly for the patient. A stable sintering process is the foundation for achieving this goal.

Achieving Unmatched Strength and Durability

A stable furnace maintains an exact temperature for a specific duration. This allows the ceramic particles to fuse completely and uniformly, creating an incredibly dense and hard final product.

This process, when executed with precision, results in restorations that can withstand the significant bite forces exerted in a patient's mouth, minimizing the risk of fractures or failures.

Ensuring a Perfect Anatomical Fit

Inconsistent heating or cooling can cause a restoration to warp or shrink unpredictably. This leads to a poor fit, requiring time-consuming manual adjustments or a complete remake.

A furnace with high stability executes precise heating and cooling cycles, known as ramp rates. This controlled process preserves the restoration's exact structural integrity from the digital design, ensuring it fits perfectly with no internal stress.

Guaranteeing Batch-to-Batch Consistency

For a dental lab, predictability is paramount. A stable furnace ensures that the tenth restoration sintered in a day is identical in quality to the first one.

By maintaining consistent temperature and atmospheric conditions, the furnace removes process variables. This guarantees uniform quality across every unit in every batch, building trust with clinicians.

The Core Features That Drive Stability

Stability isn't an accident; it's the result of specific engineering and design choices. When evaluating a furnace, these are the features that directly contribute to a reliable process.

Precision Temperature Control

This is the most critical feature. The ability to hold a temperature within a very tight tolerance (e.g., +/- 1°C) is essential for activating the specific properties of modern ceramic materials.

Controlled Ramp Rates

The speed at which the furnace heats up and cools down is just as important as the peak temperature. Slow, controlled ramps prevent thermal shock, which can introduce microscopic cracks and compromise the restoration's long-term durability.

High-Quality Heating Elements

Heating elements, such as those made from silicon carbide, provide more uniform heat distribution throughout the chamber. This eliminates hot or cold spots, ensuring the entire restoration is sintered evenly.

Automated, Programmable Cycles

Modern computerized furnaces allow labs to save specific programs for different materials. This automation eliminates human error and ensures that the exact, manufacturer-recommended sintering cycle is followed perfectly every time.

Understanding the Trade-offs in Furnace Selection

Choosing a furnace involves balancing several factors. Understanding these trade-offs is key to making a sound investment that aligns with your lab's goals.

Initial Cost vs. Long-Term ROI

Less expensive furnaces often lack the precise temperature control and high-quality components needed for consistent results. This can lead to a higher rate of failed restorations, costing more in wasted materials, labor, and time than a more reliable unit would have.

Feature Set vs. Practical Need

Features like cloud connectivity and advanced diagnostics can be valuable but may not be necessary for every lab. It is crucial to prioritize core performance—temperature accuracy and reliability—over features that don't directly contribute to the quality of the final product.

Chamber Size and Throughput

A larger chamber allows for more units to be sintered at once, increasing throughput. However, a larger chamber also requires more power and robust heating elements to maintain temperature uniformity. Your choice must balance current case volume with plans for future growth.

Making the Right Choice for Your Lab

Your final decision should be guided by the specific priorities of your practice or laboratory.

- If your primary focus is clinical quality: Prioritize furnaces with the most precise temperature control, verifiable ramp rates, and high-quality silicon carbide heating elements.

- If your primary focus is operational efficiency: Look for a reliable furnace with a chamber size that matches your throughput needs and features automated, programmable cycles to minimize hands-on time.

- If your primary focus is material versatility: Ensure the furnace you choose is certified and fully programmable for the wide range of ceramic materials you plan to use now and in the future.

Ultimately, investing in a furnace with proven stability is a direct investment in the consistency, quality, and reputation of your work.

Summary Table:

| Benefit | Description |

|---|---|

| Strength & Durability | Uniform particle fusion for dense, fracture-resistant restorations. |

| Anatomical Fit | Controlled heating/cooling prevents warping for accurate fit. |

| Batch Consistency | Reliable temperature control ensures identical quality across units. |

Upgrade your dental lab with KINTEK's advanced sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing restoration quality and operational efficiency. Contact us today to discuss how our reliable furnaces can elevate your clinical outcomes and boost your ROI!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations