Hot Isostatic Pressing (HIP) provides a distinct advantage over standard annealing by subjecting Ti6Al4V components to simultaneous high temperature and extreme gas pressure (up to 300 MPa). Unlike standard furnaces which rely solely on thermal cycles, this combination actively eliminates internal voids to achieve near-full density and superior mechanical resilience.

The core differentiator is the synergistic application of heat and pressure. While standard furnaces treat the material thermally, HIP utilizes pressure to physically close residual micro-pores, resulting in fine, fragmented lamellar structures that standard annealing cannot produce.

The Mechanism of Densification

Simultaneous Heat and Pressure

Standard annealing furnaces operate primarily through temperature control. In contrast, HIP equipment introduces a critical second variable: extreme gas pressure reaching levels such as 300 MPa.

Elimination of Internal Defects

This intense pressure works in concert with high temperatures to collapse internal voids. The process effectively closes residual micro-pores and defects within the Ti6Al4V material, creating a level of material solidity that thermal treatment alone cannot achieve.

Achieving Near-Full Density

The primary physical result of this process is the achievement of near-full density. By physically forcing material into void spaces, the structural integrity of the component is maximized at a microscopic level.

Microstructural Transformation

Fine, Fragmented Lamellar Structures

The impact of HIP extends beyond simple density to the crystalline structure of the alloy. The process promotes the formation of a fine, fragmented lamellar microstructure.

Superiority Over Standard Furnace Output

Parts processed in standard furnaces typically develop coarser structures. The refined microstructure generated by HIP is a direct contributor to the enhanced performance characteristics of the final part.

Measurable Performance Gains

Enhanced Fatigue Strength

The reduction of porosity and the refinement of the microstructure directly improve the material's resistance to cyclic loading. HIP-treated parts exhibit significantly higher fatigue strength compared to their furnace-annealed counterparts.

Improved Fracture Elongation

In addition to strength, the material's ductility is positively affected. The specific microstructural changes allow for greater fracture elongation, meaning the material can withstand more deformation before failing.

Understanding the Comparison

The Limits of Standard Annealing

It is critical to understand that standard annealing furnaces are limited to thermal stress relief and phase transformation. Without the element of isostatic pressure, they cannot actively close existing porosity or densify the material.

The Necessity of Synergy

The benefits of HIP are not derived from heat or pressure in isolation, but from their synergistic effect. It is this combination that unlocks the specific mechanical properties required for high-performance applications.

Making the Right Choice for Your Goal

To determine if HIP is the correct optimization route for your Ti6Al4V components, consider your specific mechanical requirements.

- If your primary focus is maximizing cyclic durability: HIP is essential because it closes the micro-pores that typically serve as crack initiation sites, significantly boosting fatigue strength.

- If your primary focus is material ductility: HIP provides the necessary microstructural refinement to improve fracture elongation, allowing for greater deformation before failure.

By integrating extreme pressure with thermal processing, HIP transforms Ti6Al4V from a standard alloy into a fully densified, high-performance material.

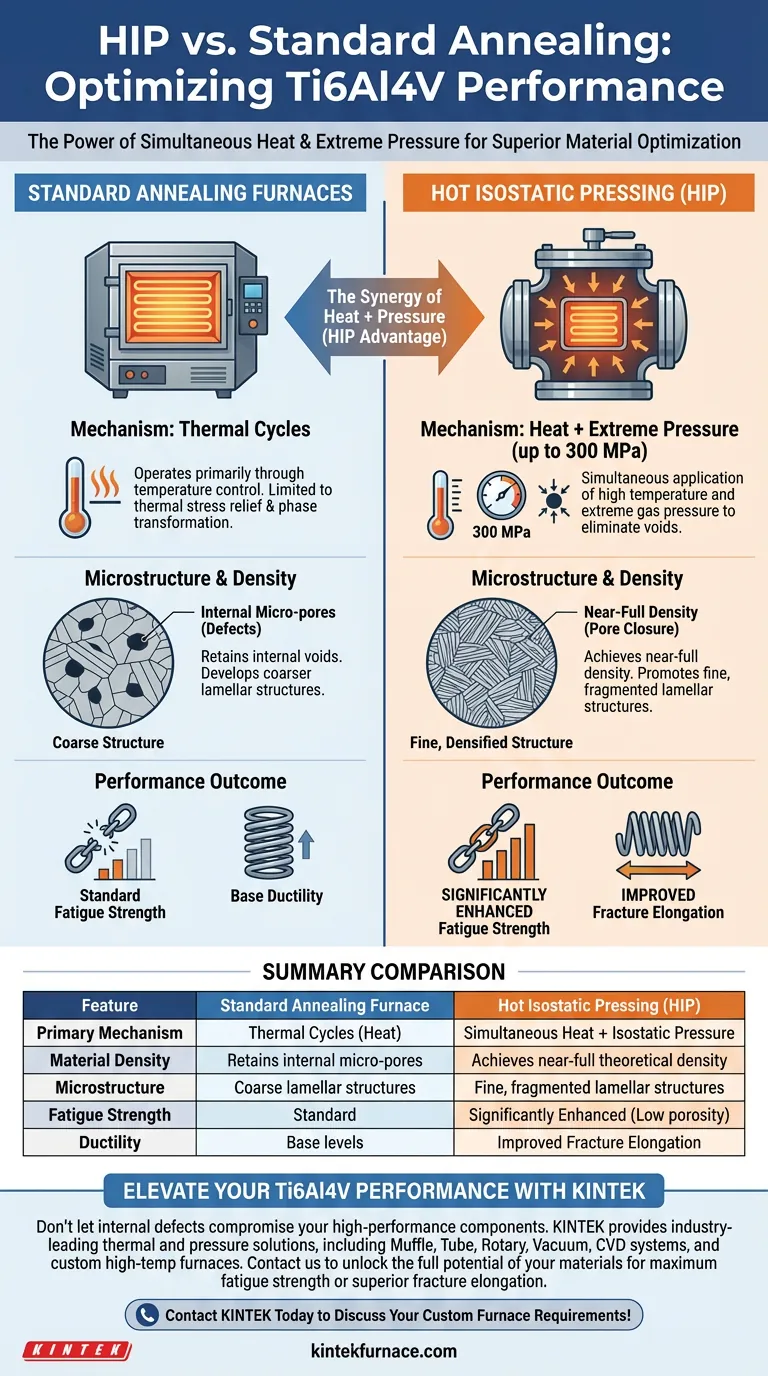

Summary Table:

| Feature | Standard Annealing Furnace | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Primary Mechanism | Thermal Cycles (Heat) | Simultaneous Heat + Isostatic Pressure |

| Material Density | Retains internal micro-pores | Achieves near-full theoretical density |

| Microstructure | Coarse lamellar structures | Fine, fragmented lamellar structures |

| Fatigue Strength | Standard | Significantly Enhanced (Low porosity) |

| Ductility | Base levels | Improved Fracture Elongation |

Elevate Your Ti6Al4V Performance with KINTEK

Don't let internal defects compromise your high-performance components. KINTEK provides industry-leading thermal and pressure solutions designed to unlock the full potential of your materials. Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable high-temp furnaces tailored to your unique metallurgy needs.

Whether you require maximum fatigue strength or superior fracture elongation, our team is ready to help you optimize your process. Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Anna Antolak‐Dudka, Justyna Łukasiewicz. Comparison of the Microstructural, Mechanical and Corrosion Resistance Properties of Ti6Al4V Samples Manufactured by LENS and Subjected to Various Heat Treatments. DOI: 10.3390/ma17051166

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum carburizing compare to traditional carburizing methods in terms of environmental impact? Discover Eco-Friendly Heat Treatment

- Which metals are prone to oxidation during melting? Protect with vacuum or inert gas furnaces

- What critical tasks does a vacuum drying oven perform for WPU films? Ensure Defect-Free Composite Material Integrity

- What control options are available for vacuum annealing furnaces? Explore PLC, Modes, and Precision Control

- What are the specifications of the hot zone construction in the vacuum furnace system? Optimize Your High-Temp Processing Today

- How should a crucible be handled after being heated in a vacuum furnace? Ensure Material Integrity & Accurate Results

- How are vacuum annealing furnaces utilized in electronic material research and development? Unlock Purity and Precision for Advanced Electronics

- What is sintering in a vacuum atmosphere? Achieve Maximum Purity for High-Performance Parts