At its core, vacuum carburizing is a fundamentally cleaner and more environmentally friendly process than traditional atmosphere-based methods. It achieves this by operating in a controlled vacuum, which eliminates the continuous production of greenhouse gas emissions, removes the need for hazardous chemical disposal, and creates a safer, non-toxic working environment.

The environmental advantages of vacuum carburizing extend beyond just emissions. The process's precision and efficiency lead to higher-quality parts, which minimizes material waste, reduces energy-intensive rework, and eliminates the need for secondary chemical cleaning operations.

The Core Environmental Advantages

Traditional carburizing methods, such as gas or salt bath carburizing, rely on creating and maintaining a carbon-rich atmosphere or liquid. This approach, while effective, carries inherent environmental and safety liabilities that vacuum carburizing was designed to solve.

Elimination of Process Emissions

In traditional gas carburizing, an endothermic gas generator combusts natural gas to create a carrier gas (CO, H₂, N₂). This gas is then fed into the furnace, and the excess is burned off in a flue, continuously releasing CO₂ and other combustion byproducts.

Vacuum carburizing completely eliminates this. The process uses a vacuum, introducing a small, precise amount of a hydrocarbon gas (like acetylene) which is fully consumed, leaving no ongoing emissions.

No Hazardous Chemical Waste

Methods like salt bath carburizing generate toxic cyanide salt waste that requires specialized and costly hazardous waste disposal protocols. This creates a significant long-term environmental liability.

Vacuum carburizing produces no such liquid or solid hazardous waste. The process is self-contained, and the byproducts are negligible and non-toxic.

Improved Energy Efficiency

Traditional atmosphere furnaces must run continuously to maintain their thermal and atmospheric stability, consuming significant energy even when idle.

Vacuum furnaces are batch-based and better insulated. They only consume high levels of energy during the actual heating cycle, resulting in lower overall energy consumption per pound of steel processed.

Secondary Benefits with Environmental Impact

The precision of the vacuum process creates a cascade of positive effects that further reduce its total environmental footprint compared to traditional methods.

Reduced Post-Processing

Parts from a vacuum furnace are clean and free of the surface oxides that form in atmosphere-based treatments.

This cleanliness eliminates the need for secondary cleaning operations like shot blasting or chemical washing, both of which consume energy, create dust or chemical waste, and add cost.

Minimized Material Waste and Rework

Vacuum carburizing provides exceptional temperature uniformity and precise control over the carbon diffusion. This results in highly consistent and predictable case depths across the entire workload.

This consistency allows designers to specify less grinding stock, reducing material waste and the energy spent on finish grinding. It also drastically lowers the rate of scrapped parts due to distortion or inconsistent heat treatment.

Safer Working Conditions

Traditional carburizing involves open flames, flammable atmospheres, and exposure to high levels of carbon monoxide. This presents significant safety risks and requires complex ventilation.

The sealed, automated nature of vacuum carburizing creates a clean, cool, and non-toxic work environment, which is a critical component of modern environmental and social governance (ESG) standards.

Understanding the Trade-offs

While environmentally and technically superior, vacuum carburizing is not a universal replacement for all applications. Acknowledging the trade-offs is crucial for a sound technical decision.

Initial Capital Investment

Vacuum furnace systems typically have a higher upfront acquisition cost compared to conventional atmosphere furnaces. This is a primary consideration for any business evaluating the technology.

Process Cycle Time

For some part geometries, the overall floor-to-floor time for a vacuum carburizing batch can be longer than for a continuous atmosphere furnace processing a similar volume.

Maintenance and Operational Expertise

Operating and maintaining a high-vacuum system requires a specific skill set. Technicians must be proficient with vacuum pumps, seals, and sophisticated control systems, which can differ from the expertise needed for traditional furnaces.

Making the Right Choice for Your Goal

The decision between vacuum and traditional carburizing depends on balancing your operational priorities with your environmental and quality objectives.

- If your primary focus is environmental compliance and worker safety: Vacuum carburizing is the definitive choice, as it eliminates process emissions, hazardous waste, and workplace atmospheric hazards.

- If your primary focus is part quality and reducing total production cost: Vacuum carburizing often provides a lower total cost of ownership through reduced scrap, rework, and secondary processing, justifying its higher initial investment.

- If your primary focus is processing extremely high volumes of a low-mix part: A large-scale, continuous atmosphere furnace may still offer a lower cost-per-part, but this comes at the expense of environmental performance and process flexibility.

Ultimately, adopting vacuum carburizing is a strategic decision that aligns superior metallurgical outcomes with clear environmental responsibility.

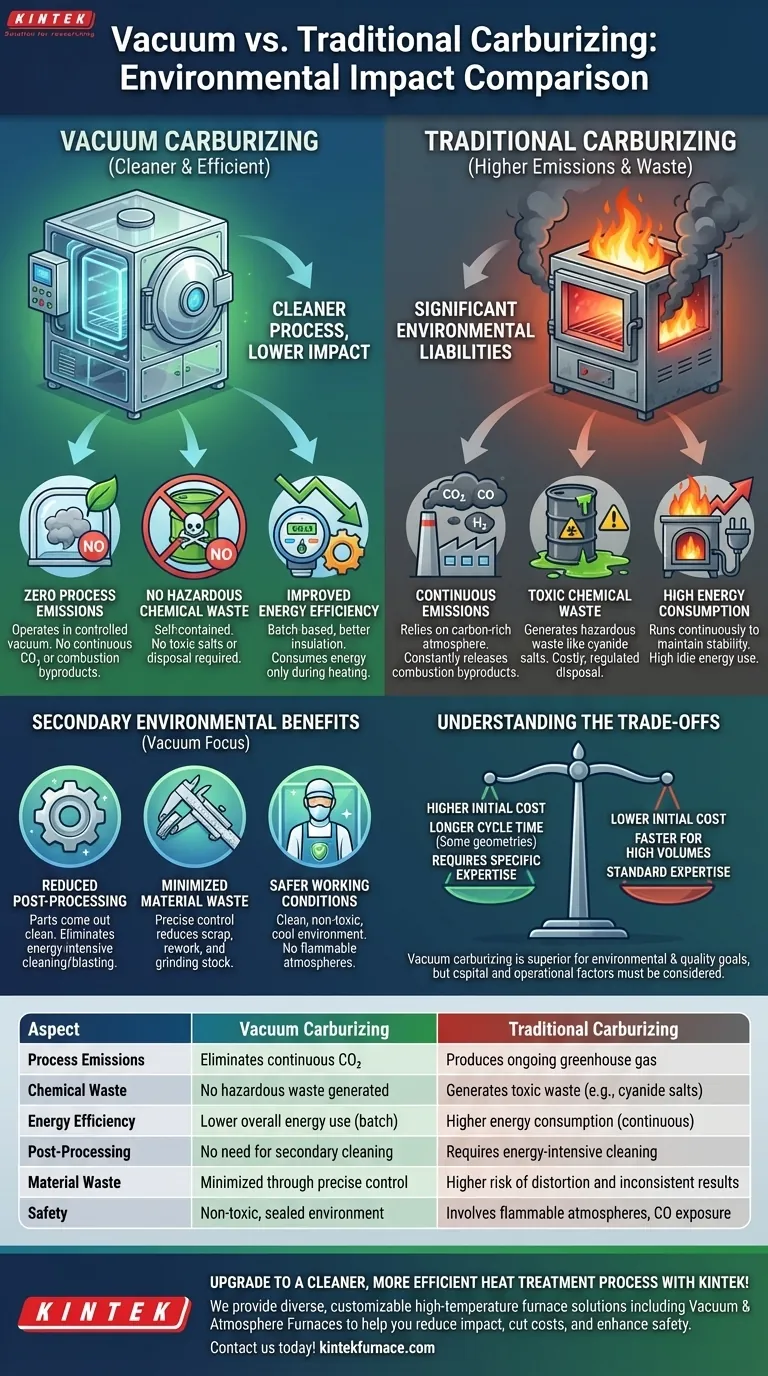

Summary Table:

| Aspect | Vacuum Carburizing | Traditional Carburizing |

|---|---|---|

| Process Emissions | Eliminates continuous CO₂ and combustion byproducts | Produces ongoing greenhouse gas emissions |

| Chemical Waste | No hazardous waste generated | Generates toxic waste (e.g., cyanide salts) |

| Energy Efficiency | Lower overall energy use due to batch processing and better insulation | Higher energy consumption from continuous operation |

| Post-Processing | No need for secondary cleaning, reducing waste and energy | Requires energy-intensive cleaning (e.g., shot blasting) |

| Material Waste | Minimized through precise control, reducing scrap and rework | Higher risk of distortion and inconsistent results |

| Safety | Non-toxic, sealed environment with reduced risks | Involves flammable atmospheres and exposure to carbon monoxide |

Upgrade to a cleaner, more efficient heat treatment process with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you reduce environmental impact, cut costs, and enhance safety. Contact us today to discuss how our tailored solutions can transform your operations!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the working principles of a box furnace and a vacuum furnace? Choose the Right Furnace for Your Lab

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What operational advantages do vacuum furnaces provide? Achieve Superior Material Quality and Process Control