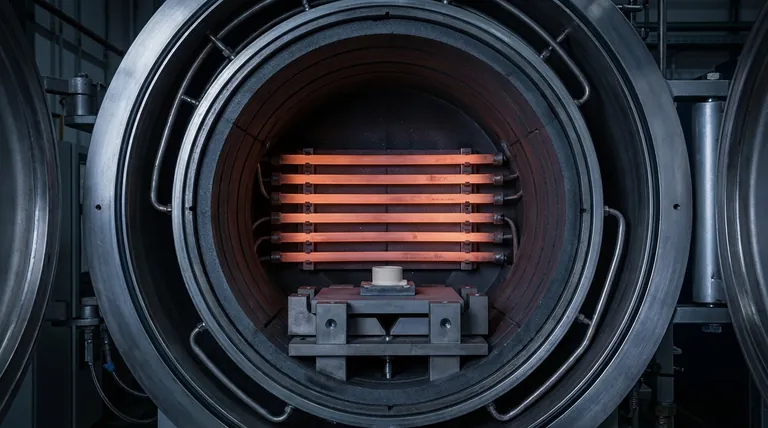

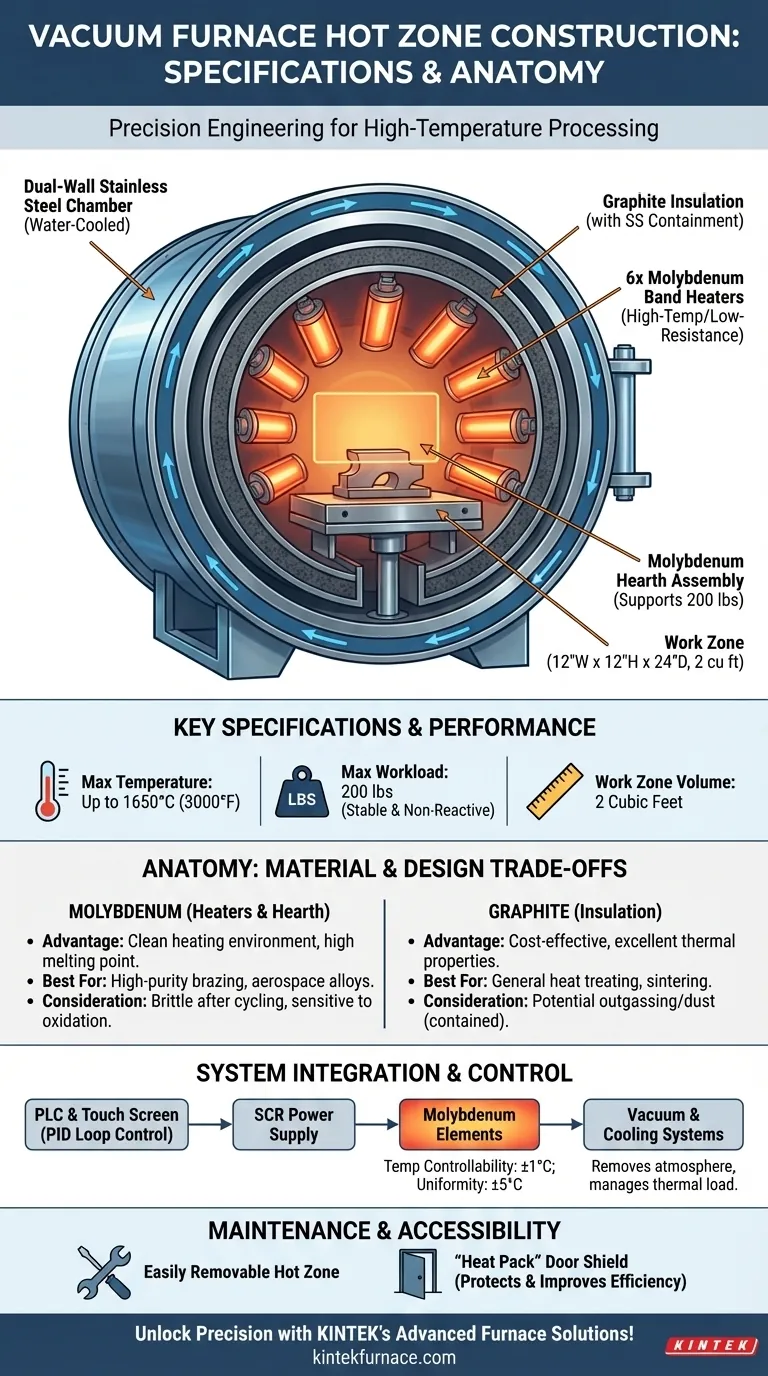

The hot zone of this vacuum furnace system is a precisely engineered environment designed for high-temperature processing. It features a round, horizontally-mounted work zone measuring 12 inches wide by 12 inches high by 24 inches deep, with a total volume of two cubic feet. This zone is constructed with six molybdenum band heating elements, graphite insulation, and a molybdenum hearth assembly capable of supporting a 200-pound workload.

Understanding a vacuum furnace's hot zone construction is not just about a list of parts. It's about recognizing how the specific materials—in this case, molybdenum and graphite—and the design directly dictate the furnace's temperature capabilities, process cleanliness, and overall performance.

Anatomy of the Hot Zone: A Component-by-Component Analysis

The hot zone is the heart of the furnace, where the critical thermal processing takes place. Its design is a balance of performance, durability, and serviceability.

The Usable Work Zone and Hearth

The specified work zone dimensions of 12" W x 12" H x 24" D define the maximum size of a part or batch that can be processed.

The workload is supported by a molybdenum hearth assembly. This material is chosen for its exceptional strength at high temperatures, ensuring a stable, non-reactive platform for the parts during the thermal cycle.

Heating Elements: The Molybdenum Core

The heat is generated by six molybdenum 2" band heater elements. Molybdenum is a refractory metal ideal for high-vacuum, high-temperature applications.

These elements are described as "high temp/low resistance," which allows for high power input to achieve rapid heating rates and ultimate temperatures up to 1650°C (3000°F) or higher, depending on the furnace series.

Insulation: Containing the Heat

The heating elements are surrounded by graphite insulation. This material has excellent thermal properties and is stable at extreme temperatures in a vacuum, effectively reflecting radiant heat back into the work zone.

This insulation is held within stainless steel containment, which provides structural support and helps minimize particulate contamination from the graphite fibers.

Accessibility and Maintenance

The design prioritizes serviceability. The complete hot zone is easily removable, which dramatically simplifies maintenance tasks like element replacement or insulation repair.

An electro-pneumatically operated 'Heat Pack' door shield protects the main chamber door from extreme radiant heat, improving energy efficiency and extending the life of the door seals.

How the Hot Zone Integrates with the Broader System

The hot zone does not operate in isolation. Its performance is directly enabled and controlled by the larger furnace system.

The Stainless Steel Chamber

The hot zone is housed within a dual-wall, water-cooled stainless steel chamber. This robust construction contains the vacuum environment and actively removes waste heat, keeping the external surfaces of the furnace safe to the touch.

The chamber is designed for working pressures from a high vacuum up to 2-bar positive pressure, allowing for vacuum processing followed by gas quenching or backfilling.

Reaching and Controlling Temperature

The system's control panel, featuring a PLC and color touch screen, governs the hot zone. It executes programmed heating profiles with precise PID loop control.

An SCR Power Supply regulates the electrical energy sent to the molybdenum elements, enabling temperature controllability of +/- 1°C and achieving a nominal uniformity of +/- 5°C across the workload.

The Vacuum and Cooling Systems

The entire process relies on the vacuum system to remove atmosphere from the chamber, preventing oxidation and other unwanted chemical reactions at high temperatures.

Simultaneously, a water-cooling system circulates through the chamber walls and power feed-throughs, which is critical for managing the immense thermal load and maintaining the integrity of the system.

Understanding the Trade-offs: Molybdenum vs. Graphite

The choice to use both molybdenum (for heaters and hearth) and graphite (for insulation) is a significant design decision with specific trade-offs.

The Molybdenum Advantage

Molybdenum provides an exceptionally clean heating environment. It is ideal for processing materials that are highly sensitive to carbon contamination, such as certain medical implants or aerospace alloys. Its high melting point allows for very high process temperatures.

The Graphite Insulation Role

Graphite is a cost-effective and highly effective insulator for high-temperature vacuum applications. It is lightweight and has very low thermal conductivity.

However, graphite can be a source of fine carbon dust and can release absorbed gases ("outgassing"), which might be a concern for the most ultra-clean processes. The stainless steel containment is designed to mitigate this.

Lifespan and Operating Conditions

Molybdenum elements can become brittle after repeated high-temperature thermal cycles and are sensitive to oxidation if the vacuum level is poor. Graphite insulation is robust but can be damaged by rapid gas flows or mechanical impact during loading.

Making the Right Choice for Your Goal

To determine if this configuration is right for you, consider your primary process requirements.

- If your primary focus is high-purity brazing or annealing: The molybdenum heating elements and hearth provide a clean, carbon-free environment that is critical for maintaining metallurgical integrity.

- If your primary focus is general-purpose heat treating or sintering: The combination of durable molybdenum elements and cost-effective graphite insulation offers a balanced, high-performance solution for a wide range of applications.

- If your primary focus is operational uptime and repeatability: The easily removable hot zone design, coupled with precise PLC-based controls, ensures that maintenance is efficient and process results are consistent.

By understanding how these individual components function together, you can confidently evaluate whether this furnace's hot zone meets the precise demands of your application.

Summary Table:

| Component | Specification | Key Feature |

|---|---|---|

| Work Zone Dimensions | 12" W x 12" H x 24" D | 2 cubic feet volume for part processing |

| Heating Elements | 6 molybdenum band heaters | High-temp, low-resistance for up to 1650°C |

| Insulation | Graphite with stainless steel containment | Excellent heat reflection and durability |

| Hearth Assembly | Molybdenum | Supports 200 lbs, stable and non-reactive |

| Temperature Control | PLC with PID loop | ±1°C precision, ±5°C uniformity |

| Maintenance | Removable hot zone | Easy access for element replacement and repairs |

Unlock Precision in Your Laboratory with KINTEK's Advanced Furnace Solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need high-purity brazing, general heat treating, or reliable sintering, our expertise ensures optimal performance and efficiency.

Ready to enhance your processes? Contact us today for a tailored consultation and discover how KINTEK can drive your success!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance