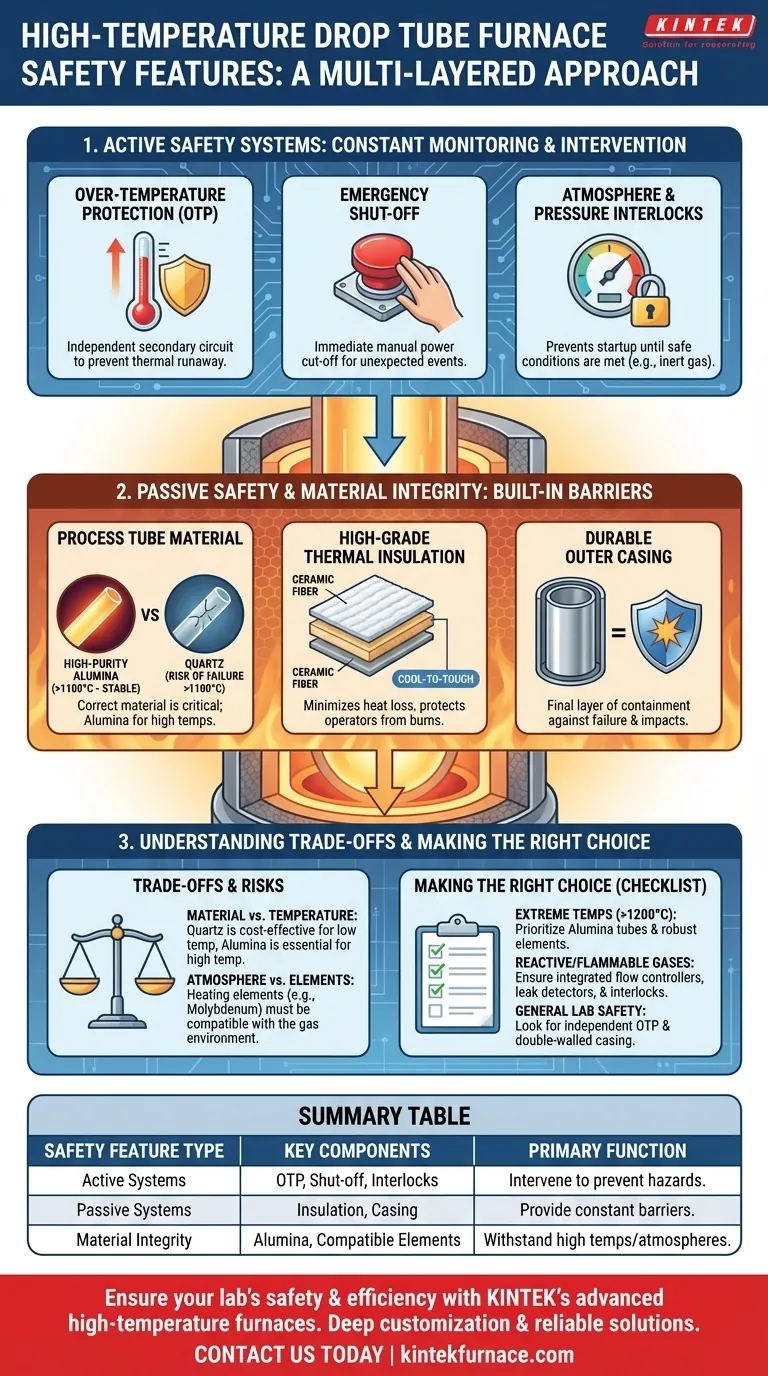

Essential safety in a high-temperature drop tube furnace is achieved through a multi-layered system. The most critical features include active controls like independent over-temperature protection and emergency shut-offs, passive systems such as high-grade thermal insulation and a durable outer casing, and fundamental material integrity, ensuring the process tube itself is correctly specified for the intended temperature and atmosphere.

True furnace safety is not about a single feature, but a holistic design philosophy. It's the integration of active electronic safeguards, passive physical barriers, and correct material selection working in concert to protect the operator, the experiment, and the equipment from failure.

Active Safety Systems: The First Line of Defense

Active systems are designed to constantly monitor the furnace's operation and intervene automatically or manually to prevent a hazardous situation.

Over-Temperature Protection (OTP)

This is the single most important active safety feature. A reliable OTP is an independent secondary control circuit with its own thermocouple.

If the primary temperature controller or its sensor fails, the OTP circuit will cut power to the heating elements, preventing a thermal runaway that could destroy the furnace and the sample.

Emergency Shut-Off

An emergency shut-off is a physical, clearly marked button that immediately cuts all power to the furnace.

This system allows for immediate manual intervention by the operator in case of an unexpected event, such as a process tube crack, a gas leak, or any other perceived emergency.

Atmosphere and Pressure Interlocks

Many high-temperature processes require a specific atmosphere (e.g., inert gas or vacuum). Safety interlocks can prevent the heating cycle from starting until the correct pressure or gas flow is established.

This prevents the catastrophic oxidation of sensitive samples or internal furnace components, such as certain heating elements that are destroyed by oxygen at high temperatures.

Passive Safety & Material Integrity: The Foundation of Security

Passive features are built into the physical design of the furnace. They provide a constant, reliable barrier against inherent hazards like extreme heat.

The Critical Role of the Process Tube

The process tube is the heart of the furnace and a primary point of failure. Using the wrong material is a major safety risk.

For temperatures consistently above 1100°C, quartz tubes are inadequate as they will soften and fail. High-purity alumina or corundum tubes are required for their high-temperature resistance and chemical stability.

High-Grade Thermal Insulation

The furnace cavity is lined with layers of high-temperature ceramic or refractory fiber insulation.

This insulation serves two safety functions: it minimizes heat loss for energy efficiency and, more importantly, it keeps the outer casing of the furnace at a safe, "cool-to-touch" temperature to protect operators from severe burns.

Durable Outer Casing

The outer shell, typically made of double-layered stainless steel or a similar alloy, provides the final layer of containment.

It protects the internal components from accidental impacts and ensures that in the unlikely event of an internal failure, the hazardous materials and high heat are contained.

Understanding the Trade-offs and Risks

A safe design requires understanding the interplay between different components and making informed choices.

Material Selection vs. Temperature

While quartz is suitable and cost-effective for lower-temperature work, pushing it beyond its limits is dangerous. Investing in a high-purity alumina tube is not a luxury but a necessity for safe, repeatable high-temperature experiments.

Atmosphere vs. Heating Elements

Not all heating elements are compatible with all atmospheres. For example, silicon molybdenum rod elements can operate in air, while pure molybdenum elements will rapidly oxidize and fail if heated in an oxygen-rich environment. The furnace's atmosphere control system must be compatible with its heating elements.

The Illusion of "Set-and-Forget"

No safety system can replace a well-trained and attentive operator. Regular inspection of the process tube for cracks, ensuring gas connections are secure, and understanding the furnace's normal operating sounds are all part of a robust safety culture.

Making the Right Choice for Your Application

Select a furnace based on a clear understanding of your experimental needs and the corresponding safety requirements.

- If your primary focus is extreme temperatures (above 1200°C): Prioritize furnaces with high-purity alumina tubes and robust heating elements like silicon molybdenum or pure molybdenum designed for your target atmosphere.

- If your primary focus is working with reactive or flammable gases: Ensure the furnace has integrated gas flow controllers, leak detectors, and safety interlocks that prevent heating until a safe environment is established.

- If your primary focus is general lab safety and frequent use: Look for a certified design with an independent over-temperature protection circuit and a double-walled casing that ensures a low external surface temperature.

A truly safe furnace is one where every component has been intentionally selected to prevent failure before it happens.

Summary Table:

| Safety Feature Type | Key Components | Primary Function |

|---|---|---|

| Active Systems | Over-temperature protection, Emergency shut-off, Atmosphere/pressure interlocks | Automatically or manually intervene to prevent hazards like thermal runaway or gas leaks |

| Passive Systems | High-grade thermal insulation, Durable outer casing | Provide constant barriers against heat and physical damage |

| Material Integrity | High-purity alumina tubes, Compatible heating elements | Ensure components withstand high temperatures and specific atmospheres without failure |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, providing reliable solutions for high-temperature operations. Contact us today to discuss how we can enhance your lab's performance and safety!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing