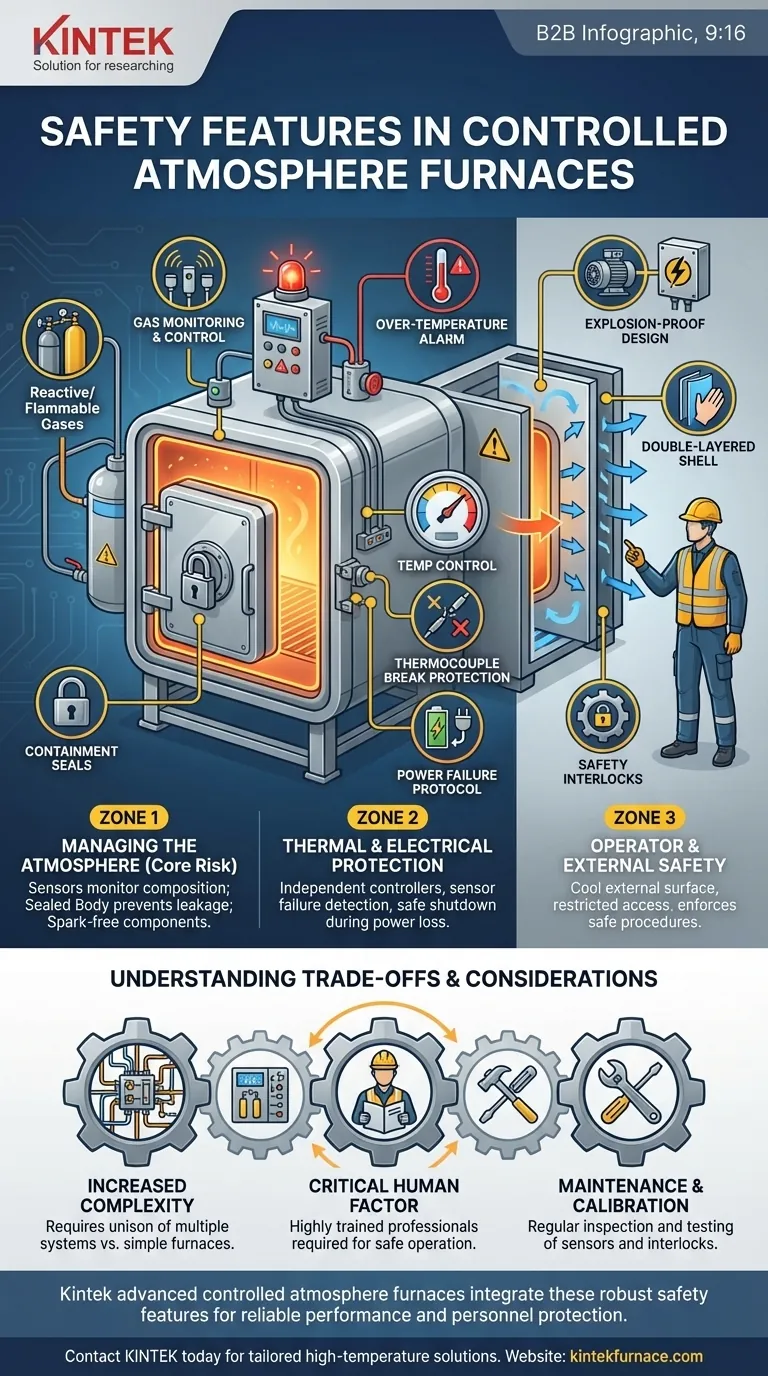

The primary safety features of a controlled atmosphere furnace are designed to manage the three core risks: the reactive gas atmosphere, high temperatures, and system pressure. These include sophisticated gas monitoring systems, multiple layers of thermal protection like over-temperature alarms and double-walled construction, and robust containment seals to prevent atmosphere leakage.

A controlled atmosphere furnace introduces risks not present in standard furnaces, namely flammable, explosive, or reactive gases. Consequently, its safety is not a single feature but a multi-layered system designed to contain the atmosphere, control temperature, and prevent ignition sources.

The Fundamental Risk: Managing the Atmosphere

The defining characteristic of these furnaces is the introduction of an artificial atmosphere. This atmosphere, while essential for processes like carburizing or bright quenching, is also the primary source of operational risk.

Gas Monitoring and Control

The system must constantly monitor the composition and pressure of the internal atmosphere. Sensors are installed to detect leaks of flammable or toxic gases into the surrounding work area, triggering alarms and potential shutdowns.

Atmosphere Containment

To be effective and safe, the furnace atmosphere must be isolated. This is achieved through tightly sealed doors and a fully welded furnace body, which prevent the controlled atmosphere from leaking out and external air from leaking in. An uncontrolled mix can create an explosive environment.

Explosion-Proof Design

When flammable gases like hydrogen or methane are used, any component that could create a spark is a significant hazard. These furnaces often incorporate explosion-proof devices, such as specially designed circulation fans, motors, and electrical enclosures, to eliminate potential ignition sources.

Protecting Against Thermal and Electrical Hazards

Beyond the unique risks of the gas atmosphere, these furnaces must manage the universal hazards associated with high-temperature industrial equipment.

Over-Temperature and Under-Temperature Protection

Furnaces are equipped with independent safety controllers that monitor the temperature. If the primary controller fails and the temperature exceeds a set limit (over-temperature), this safety system will cut power to the heating elements. Under-temperature protection ensures the process is not running in an unsafe or ineffective state.

Thermocouple Break Protection

A thermocouple is the primary temperature sensor. If this sensor breaks or becomes disconnected, the control system could mistakenly believe the furnace is cold and apply full power indefinitely. Thermocouple break protection detects this failure and safely shuts the system down.

Power Failure Protocols

A sudden power loss can be dangerous, as it may stop circulation fans or control systems while the furnace remains hot. Safety systems ensure the furnace enters a safe, predictable state during a power failure, often involving closing gas valves automatically.

Operator and External Protection

To protect personnel, these furnaces use a double-layered shell or double housing. This design allows for airflow between the inner and outer walls, keeping the external surface temperature low and safe to touch, even when the interior is at extreme temperatures.

Understanding the Trade-offs

While offering advanced process control, atmosphere furnaces introduce complexities and costs not found in simpler equipment.

Increased Complexity vs. Standard Furnaces

A standard air-atmosphere box furnace requires only basic high-temperature protection. A controlled atmosphere furnace is a far more complex system, involving gas panels, flow controllers, safety interlocks, and monitoring devices that all must work in unison.

The Critical Human Factor

Hardware alone is insufficient. The use of flammable and potentially explosive gases necessitates highly trained, professional operators. Unlike basic furnaces, these systems cannot be operated without a deep understanding of the procedures and risks involved. This represents a significant investment in training and expertise.

Maintenance and Calibration Demands

The sensors and safety interlocks that ensure safe operation require regular inspection, testing, and calibration. A gas detector that is not properly calibrated provides a false sense of security. This ongoing maintenance is a critical part of the overall safety protocol.

Making the Right Choice for Your Operation

The necessary safety features depend on your specific process and priorities. A clear understanding of your goals will guide your selection.

- If your primary focus is process quality and consistency: Prioritize furnaces with exceptional atmosphere containment (sealed doors, welded shells) and precise gas and temperature control systems.

- If your primary focus is personnel safety: Insist on certified explosion-proof components, redundant gas monitoring systems, and comprehensive operator training programs.

- If your primary focus is operational reliability: Look for robust features like thermocouple break protection, clear power failure protocols, and durable, low-maintenance components.

Ultimately, safety in a controlled atmosphere furnace is achieved by viewing it as a complete system where hardware, procedures, and operator skill are all essential components.

Summary Table:

| Safety Feature Category | Key Components | Purpose |

|---|---|---|

| Gas Monitoring & Control | Gas sensors, alarms, flow controllers | Detect leaks, prevent explosive mixtures, ensure atmosphere integrity |

| Thermal & Electrical Protection | Over-temperature controllers, thermocouple break protection, power failure protocols | Prevent overheating, sensor failures, and unsafe shutdowns |

| Containment & Explosion-Proofing | Sealed doors, welded bodies, explosion-proof fans | Isolate atmosphere, eliminate ignition sources, protect personnel |

| Operator & External Safety | Double-walled shells, safety interlocks | Maintain low external temperatures, enforce safe operation procedures |

Ensure your laboratory's safety and efficiency with KINTEK's advanced controlled atmosphere furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, integrating robust safety features for reliable performance. Contact us today to discuss how our furnaces can enhance your operations and protect your team!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage