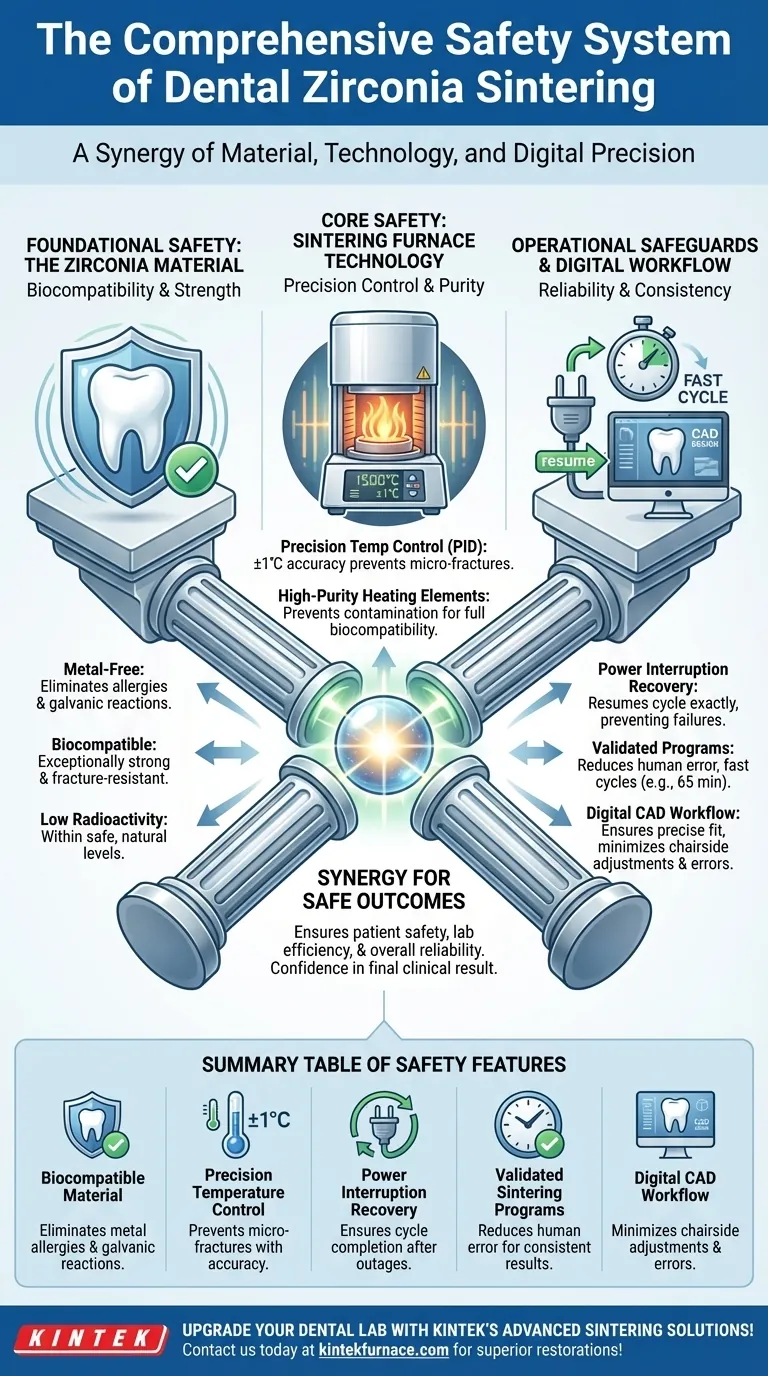

At its core, the safety of dental zirconia sintering is not a single feature but a comprehensive system. It combines the inherent biocompatibility of the material with highly controlled furnace technology and a precise digital workflow to ensure safety for both the lab operator and the end patient.

The safety of a zirconia restoration is guaranteed by a chain of trust: the metal-free, biocompatible material itself, the furnace's ability to control temperature with near-perfect accuracy, and the digital design process that ensures a flawless fit.

Foundational Safety: The Zirconia Material

Before the sintering process even begins, the choice of zirconia establishes a high baseline for patient safety.

Biocompatibility and Allergy Prevention

Zirconia is a ceramic, meaning it is entirely metal-free. This characteristic eliminates the risk of metal allergies, galvanic reactions (electrical currents between different metals in the mouth), and the metallic taste associated with some older restoration types.

Inherent Strength and Low Radioactivity

Zirconia is exceptionally strong and resistant to fracture, which contributes to the long-term safety and durability of the restoration. Furthermore, dental-grade zirconia has been rigorously tested and confirmed to have extremely low levels of radioactivity, well within the safe, naturally occurring levels found in the human body.

Core Safety Features of the Sintering Furnace

The sintering furnace is where the "green state" zirconia is transformed into its final, dense form. The equipment's features are critical for ensuring a predictable and safe outcome.

Precision Temperature Control

Modern sintering furnaces use advanced PID (Proportional-Integral-Derivative) control systems to regulate temperature with an accuracy of ±1℃. This precise control is a crucial safety feature, as it ensures uniform heating and cooling, preventing the internal stresses that can lead to micro-fractures and a compromised final restoration.

High-Purity Heating Elements

The best furnaces use high-purity heating elements, such as dental silicon molybdenum rods. This prevents pollutants or contaminants from being released into the heating chamber, ensuring the final zirconia restoration remains uncontaminated and fully biocompatible.

Environmentally Safe Insulation

Furnaces are built with green, high-purity thermal insulation materials. This not only improves heating efficiency but also ensures a safe operating environment for the lab technician, with no harmful fibers or particles released during operation.

Operational Safeguards for Reliability and Consistency

Beyond core heating technology, modern furnaces include features designed to protect the integrity of the process, which directly impacts the safety and quality of the final product.

Power Interruption Recovery

A critical operational safeguard is the power interruption recovery function. The furnace's memory allows it to resume the sintering cycle exactly where it left off after a power outage. This prevents a failed batch, ensuring the restoration is not compromised by an incomplete or incorrect heating cycle.

Validated Sintering Programs

Furnaces come with pre-set programs, including fast sintering cycles that can be completed in as little as 65 minutes. These programs are validated by the manufacturer to produce consistent, high-quality results, removing the guesswork and potential for human error in programming the cycle.

The Role of the Digital Workflow

The entire process is part of a larger digital ecosystem. The initial restoration is designed using CAD (Computer-Aided Design) software, ensuring a precise fit from the start. This digital precision minimizes the need for manual adjustments chairside, reducing appointment time and potential for iatrogenic damage to the tooth or restoration, which is a key aspect of patient safety.

Applying This to Your Goal

The safety of zirconia sintering is a result of the synergy between material science, engineering, and digital processes.

- If your primary focus is patient outcomes: Rest assured that the combination of zirconia's biocompatibility and the furnace's precision control produces a metal-free, strong, and exceptionally safe long-term restoration.

- If your primary focus is lab operations: Prioritize furnaces with proven power interruption recovery and precise PID temperature control to guarantee consistent quality, minimize waste, and ensure predictable results.

- If your primary focus is overall reliability: Understand that safety is built into the entire digital workflow, from the initial scan and design to the final, automated sintering cycle, minimizing variables and human error at every step.

Ultimately, the advanced safety features of modern zirconia sintering provide a high degree of confidence in the final clinical result.

Summary Table:

| Safety Feature | Key Benefit |

|---|---|

| Biocompatible Material | Eliminates metal allergies and galvanic reactions |

| Precision Temperature Control | Prevents micro-fractures with ±1℃ accuracy |

| Power Interruption Recovery | Ensures cycle completion after outages |

| Validated Sintering Programs | Reduces human error for consistent results |

| Digital CAD Workflow | Minimizes chairside adjustments and errors |

Upgrade your dental lab with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing safety, efficiency, and reliability. Contact us today to learn how we can support your goals for superior dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations