At its core, the quartz tube in a quartz heater performs two critical functions. It provides a protective enclosure for the internal heating element and, more importantly, it ensures that the energy produced is released efficiently as infrared radiation rather than being lost to convection.

The quartz tube is not merely a transparent shield; it is a highly engineered component designed to leverage the unique physical properties of quartz. Its primary purpose is to convert electrical energy into directional, radiant heat with maximum efficiency.

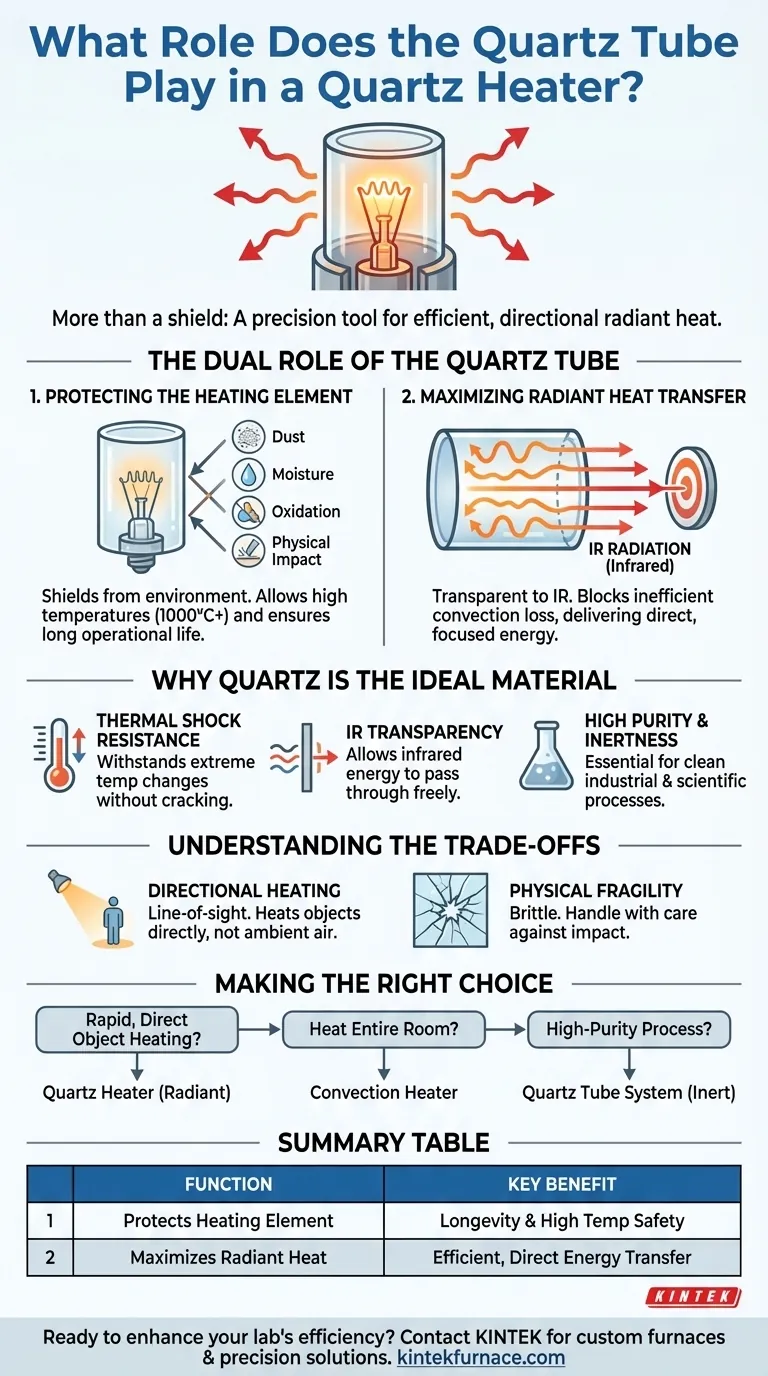

The Dual Role of the Quartz Tube

To understand a quartz heater, you must first appreciate the two distinct jobs its transparent tube performs. These functions are inseparable and define the heater's performance.

Protecting the Heating Element

The delicate wire filament that generates heat is highly susceptible to its environment. The quartz tube acts as a crucial barrier, protecting this element from oxidation, dust, moisture, and potential physical impact.

This protective enclosure is what allows the heating element to reach extremely high temperatures (often over 1000°C) safely and have a long operational life.

Maximizing Radiant Heat Transfer

This is the tube's most important function. The goal of a quartz heater is not to heat the air around it (convection), but to emit infrared (IR) radiation—a form of light that travels in a straight line and heats objects it strikes.

Quartz is uniquely suited for this because it is highly transparent to infrared radiation. The tube effectively contains the hot air and gases inside, preventing that energy from escaping as less-efficient convection heat. Meanwhile, it allows the valuable IR energy to pass straight through it with minimal loss, traveling directly to you or the object you intend to heat.

Why Quartz is the Ideal Material

Other materials like standard glass or metal would fail in this application. Fused quartz is chosen for a specific combination of properties that make it uniquely qualified for high-temperature heating.

Exceptional Thermal Shock Resistance

Quartz can withstand rapid and extreme changes in temperature without cracking. It can go from room temperature to over 1000°C and back again without failing, a property that would shatter normal glass.

Transparency to Infrared (IR) Radiation

As mentioned, this is the key. While standard glass appears clear to our eyes, it actually blocks a significant portion of the infrared spectrum. Quartz's molecular structure allows this energy to pass through, making it the perfect window for radiant heat.

High Purity and Chemical Inertness

For industrial and scientific applications, such as semiconductor manufacturing or chemical vapor deposition, purity is paramount. Quartz is exceptionally pure and does not react with most chemicals, even at high temperatures. This ensures it does not contaminate the process it is being used for.

Understanding the Trade-offs

While highly effective, the design of a quartz heater comes with inherent characteristics that are important to understand.

Directional, Not Ambient, Heating

Because a quartz heater primarily releases radiant heat, it works on a "line-of-sight" basis. It rapidly warms people and objects directly in front of it but is not effective at raising the overall air temperature of an entire room. This is a feature, not a bug.

Physical Fragility

Like any glass, quartz is brittle. While it is incredibly strong against temperature changes, the tube can be broken by a physical impact. This is a practical consideration for its placement and handling.

Making the Right Choice for Your Goal

Understanding this principle helps you select the right tool for the job.

- If your primary focus is rapid, direct heating of an object or person: A quartz heater is the most efficient choice because its radiant energy is not wasted on heating the surrounding air.

- If your primary focus is raising the temperature of an entire room: A convection-based heater, such as an oil-filled radiator or a fan heater, is a more appropriate solution.

- If your primary focus is a high-purity industrial process: The chemical inertness and thermal stability of a quartz tube heater are essential for process integrity and reliable results.

By mastering the flow of energy, the quartz tube makes the heater a precision instrument for delivering targeted, radiant heat exactly where it's needed.

Summary Table:

| Function | Key Benefit |

|---|---|

| Protects Heating Element | Shields from oxidation, dust, and moisture for longevity |

| Maximizes Radiant Heat Transfer | Enables efficient infrared radiation with minimal energy loss |

Ready to enhance your lab's heating efficiency with precision solutions? KINTEK specializes in advanced high-temperature furnaces, including custom quartz tube systems. With our strong R&D and in-house manufacturing, we deliver tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems to meet your unique experimental needs. Contact us today to discuss how we can optimize your processes with reliable, high-performance equipment!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety