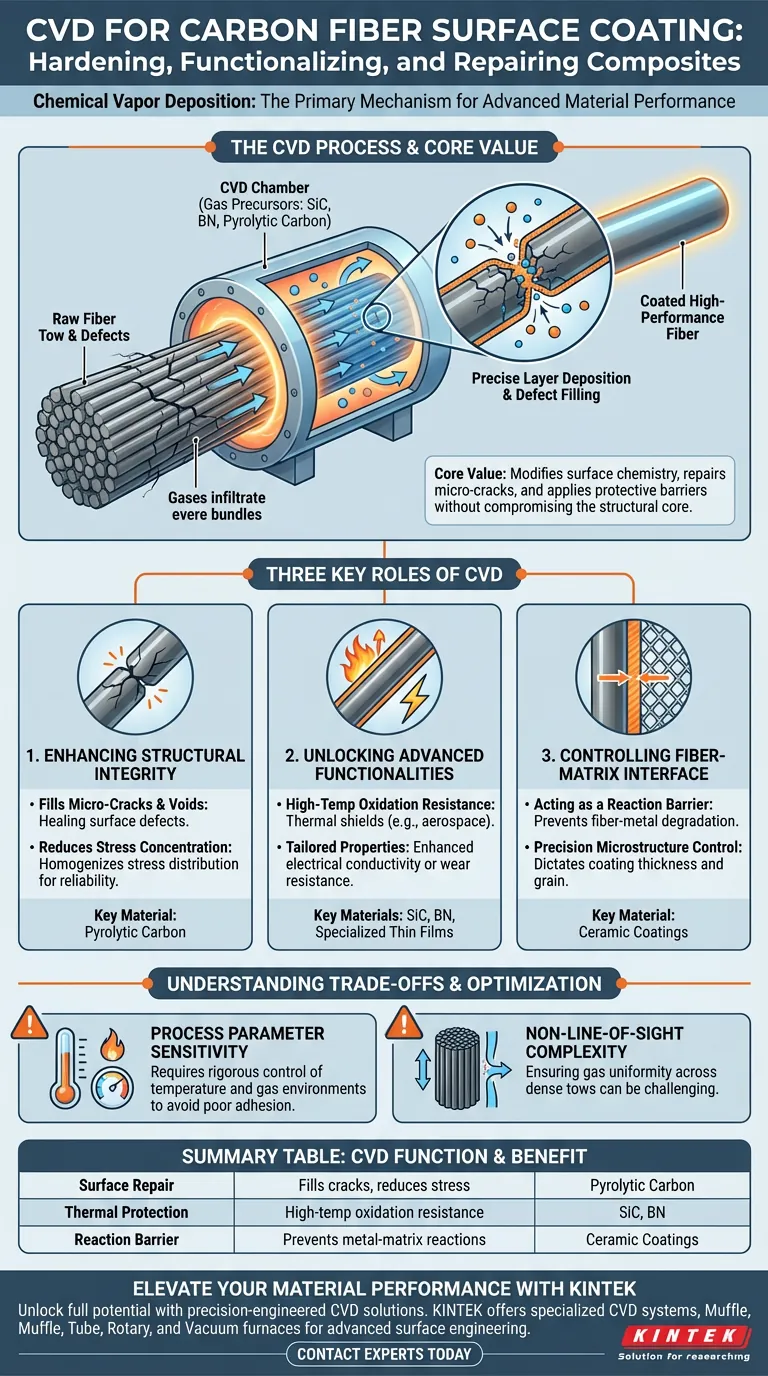

Chemical Vapor Deposition (CVD) equipment serves as the primary mechanism for hardening and functionalizing carbon fibers. It is used to deposit specialized layers—such as silicon carbide (SiC), boron nitride (BN), or pyrolytic carbon—directly onto the surface of graphitized fibers. This process is essential for repairing microscopic surface defects and enabling the fiber to survive in extreme composite manufacturing and operating environments.

The core value of CVD equipment lies in its ability to precisely modify the fiber's surface chemistry without compromising its structural core. By filling surface micro-cracks and applying uniform protective barriers, CVD transforms standard carbon fibers into high-performance reinforcements suitable for aerospace and thermal management applications.

Enhancing Structural Integrity

The surface of a raw carbon fiber is rarely perfect. CVD equipment addresses physical vulnerabilities that could lead to premature material failure.

Filling Micro-Cracks and Defects

Graphitized carbon fibers often contain inherent surface defects, such as micro-cracks or voids. CVD equipment introduces a precursor gas that infiltrates these microscopic imperfections. The deposited material fills these gaps, effectively healing the surface of the fiber.

Reducing Stress Concentration

Surface irregularities act as stress concentrators where cracks can propagate under load. By smoothing the surface profile with a deposited coating, CVD equipment homogenizes stress distribution. This significantly improves the overall mechanical reliability of the composite material.

Unlocking Advanced Functionalities

Beyond simple repair, CVD allows engineers to imbue carbon fibers with properties they do not naturally possess.

High-Temperature Oxidation Resistance

Carbon fibers degrade rapidly in oxygen-rich environments at high temperatures. CVD equipment applies ceramic coatings like SiC or BN that act as thermal shields. This allows the fibers to retain strength in aerospace engine components and thermal management systems.

Tailored Electrical and Wear Properties

Specific applications may require enhanced conductivity or resistance to abrasion. CVD enables the deposition of coatings that improve electrical conductivity or surface hardness. This versatility expands the utility of carbon fibers into complex electronic and tribological applications.

Controlling the Fiber-Matrix Interface

In composite materials, the interaction between the fiber and the surrounding matrix (polymer or metal) is critical.

Acting as a Reaction Barrier

In metal matrix composites, carbon fibers can react chemically with the molten metal, degrading the fiber. CVD coatings function as a diffusion barrier, preventing these detrimental interfacial reactions. This preserves the fiber's strength during the composite fabrication process.

Precision Microstructure Control

The performance of the coating depends heavily on its thickness and grain structure. CVD equipment offers precise control over process parameters like temperature and gas flow. This allows manufacturers to dictate the exact final diameter and microstructure of the fiber coating.

Understanding the Trade-offs

While CVD offers superior coating quality, it requires rigorous process management to ensure success.

Process Parameter Sensitivity

The quality of the coating is heavily dependent on maintaining precise gas environments and temperatures. Deviations in the reduction temperature (often between 300°C and 500°C for specific precursors) can lead to poor adhesion or aggregation. Operators must strictly monitor these variables to maintain the material's high specific surface area.

Non-Line-of-Sight Complexity

One major advantage of CVD is its ability to coat complex, non-line-of-sight geometries. However, ensuring gas uniformity across a dense bundle of fibers (tow) can be challenging. Inadequate gas flow distribution can result in uneven coating thickness across the inner filaments of a tow.

Making the Right Choice for Your Goal

To maximize the value of CVD equipment for your specific application, focus on the functional outcome you require.

- If your primary focus is High-Temperature Durability: Prioritize CVD processes capable of depositing uniform Silicon Carbide (SiC) or Boron Nitride (BN) to prevent oxidation.

- If your primary focus is Mechanical Reliability: Utilize CVD to deposit pyrolytic carbon for filling surface defects and reducing stress concentrations.

- If your primary focus is Metal Matrix Composites: Ensure your CVD setup is tuned to create dense, non-porous barrier coatings to prevent fiber-metal reactivity.

CVD equipment is not just a coating tool; it is an engineering instrument that redefines the performance limits of carbon fiber composites.

Summary Table:

| CVD Function | Benefit for Carbon Fibers | Key Coating Materials |

|---|---|---|

| Surface Repair | Fills micro-cracks and reduces stress concentration | Pyrolytic Carbon |

| Thermal Protection | Provides high-temperature oxidation resistance | SiC, BN |

| Reaction Barrier | Prevents degradation in metal matrix composites | Ceramic Coatings |

| Surface Engineering | Tailors electrical conductivity and wear resistance | Specialized Thin Films |

Elevate Your Material Performance with KINTEK

Unlock the full potential of your carbon fiber composites with precision-engineered CVD solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized CVD systems, Muffle, Tube, Rotary, and Vacuum furnaces designed to meet the rigorous demands of advanced surface engineering.

Whether you need to enhance thermal shielding, improve mechanical reliability, or develop custom interface barriers, our systems are fully customizable to your unique research and production needs.

Ready to optimize your fiber coating process? Contact our technical experts today to find the perfect high-temperature solution.

Visual Guide

References

- Advances in Acid and Post-Graphitization Treatments for Mesophase Pitch-based Carbon Fibers: A Review. DOI: 10.34257/gjsfrbvol25is1pg1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is Chemical Vapor Deposition (CVD) and what is it used for? Unlock High-Performance Thin Films

- How is CVD used in electronics manufacturing? Build High-Purity, Uniform Layers for Advanced Electronics

- What drives the precursor generation and decomposition in CVD? Master Thermodynamics and Kinetics for Superior Film Growth

- What types of heterostructures have been successfully synthesized using these CVD systems? Discover Advanced 2D Material Architectures

- How are CVD processes categorized based on operational conditions? Explore Key Types and Applications

- How is CVD applied in the production of solar cells? Enhance Efficiency with Precision Film Deposition

- What are the applications of chemical vapor deposition? Powering Modern Tech from Chips to Solar Cells

- What is the configuration of CVD furnaces? Unlock Precision Thin Film Deposition