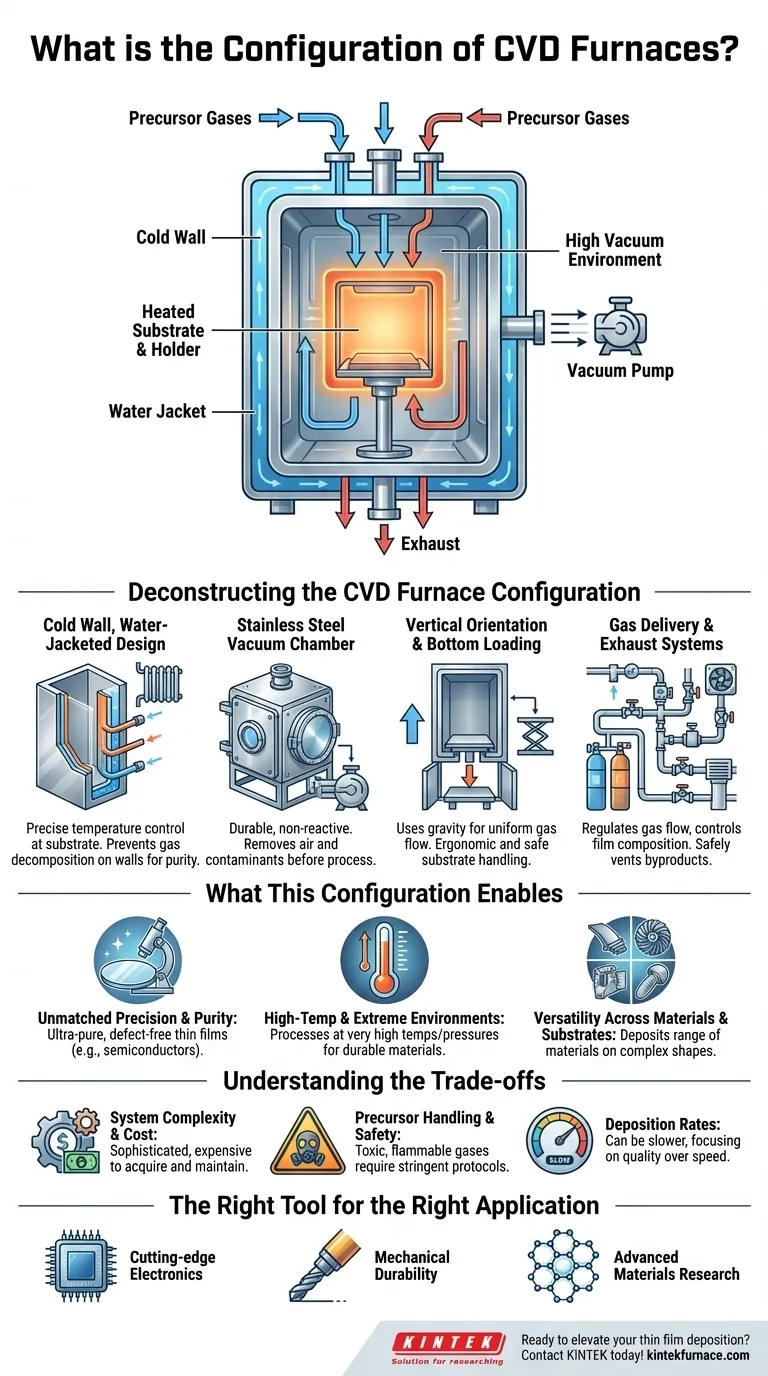

At its core, a Chemical Vapor Deposition (CVD) furnace is a highly controlled reaction chamber. The most common configuration is a cold wall, stainless steel, water-jacketed system, typically with a vertical orientation and a bottom-loading mechanism for substrates. This entire assembly is designed to operate under a high vacuum, creating a pristine environment where precursor gases can react on a heated surface to form a solid film, one atomic layer at a time.

The specific configuration of a CVD furnace is not arbitrary; every component—from the cold walls to the vacuum system—is engineered for one primary purpose: to create an ultra-pure, highly controllable environment for depositing flawless thin films on a substrate.

Deconstructing the CVD Furnace Configuration

The physical design of a CVD furnace is a direct result of the demanding requirements of the chemical vapor deposition process. Each key feature serves a critical function in achieving a pure, uniform, and high-quality coating.

The Cold Wall, Water-Jacketed Design

The term "cold wall" means that only the substrate and its immediate holder are heated, while the interior walls of the furnace chamber remain cool. This is achieved with an external water jacket that continuously circulates water, absorbing excess heat.

This design provides precise temperature control right where it matters: at the substrate surface. It prevents the precursor gases from decomposing on the chamber walls, which would waste material and introduce impurities into the process.

The Stainless Steel Vacuum Chamber

CVD furnaces are built as sealed vacuum chambers, almost always constructed from stainless steel. The vacuum is essential for removing air and any other contaminants before the process begins.

Operating well below atmospheric pressure ensures that the only molecules present are the intended precursor gases. The stainless steel construction provides durability and a non-reactive surface, preserving the purity of the chemical reactions.

Vertical Orientation and Bottom Loading

A vertical orientation is common because it uses gravity to help secure the substrate and often promotes a more uniform flow of gas around the part.

Bottom-loading mechanisms, where the base of the furnace is lowered to insert the substrate, are often more ergonomic and safer than top-loading designs, especially when working with heavy or delicate components.

Gas Delivery and Exhaust Systems

An integral part of the configuration is the precision gas delivery system. This network of pipes, valves, and mass flow controllers meticulously regulates the flow of one or more precursor gases into the chamber.

The composition of the resulting film is directly controlled by the gas mixture, and its thickness is determined by the gas concentration and deposition time. A corresponding exhaust system safely vents the unreacted gases and byproducts.

What This Configuration Enables

The unique setup of a CVD furnace unlocks capabilities that are critical for modern manufacturing and research. It is a tool of precision, chosen when the material properties of the final film are paramount.

Unmatched Precision and Purity

The combination of a high-vacuum environment and a cold-wall design creates the ideal conditions for depositing ultra-pure, defect-free thin films. This is why CVD is the backbone of the semiconductor industry for creating transistors, diodes, and integrated circuits.

High-Temperature and Extreme Environments

The robust chamber and localized heating allow for processes that run at extremely high temperatures and pressures. This is necessary to decompose certain stable precursors and to form highly durable crystalline materials like diamond films or hard coatings for cutting tools.

Versatility Across Materials and Substrates

Because the furnace walls remain cool and non-reactive, the process is highly flexible. It can be used to deposit a vast range of materials—from silicon and tungsten to graphene and silicon nitride—onto substrates of complex shapes, such as turbine blades, optical lenses, or biomedical implants.

Understanding the Trade-offs

While powerful, the CVD configuration comes with inherent complexities and challenges that must be managed.

System Complexity and Cost

CVD furnaces are sophisticated systems. The need for high-vacuum pumps, precise gas handling, and advanced temperature controllers makes them expensive to acquire, operate, and maintain.

Precursor Handling and Safety

Many precursor gases used in CVD processes are toxic, flammable, or corrosive. Operating a CVD furnace requires stringent safety protocols, leak detection systems, and proper infrastructure for gas storage and abatement.

Deposition Rates

While capable of producing exceptionally high-quality films, some CVD processes can be slower than alternative coating methods, especially when depositing very thick layers. The focus is on quality over sheer speed.

The Right Tool for the Right Application

The specific benefits of the CVD furnace configuration make it the ideal choice for applications where film quality and material properties are the primary concerns.

- If your primary focus is cutting-edge electronics: The furnace's ability to deposit ultra-pure, uniform films like silicon is essential for creating high-performance transistors and integrated circuits.

- If your primary focus is mechanical durability: The high-temperature capability is perfect for creating hard, wear-resistant coatings on tools, turbine blades, and biomedical implants.

- If your primary focus is advanced materials research: The system's flexibility allows for the synthesis of novel materials like graphene, carbon nanotubes, and components for thin-film solar cells.

Ultimately, the CVD furnace's configuration is a direct reflection of its purpose: to provide the absolute control needed to build functional materials from the atom up.

Summary Table:

| Key Component | Function |

|---|---|

| Cold Wall, Water-Jacketed Design | Enables precise temperature control at the substrate, preventing gas decomposition on walls for purity. |

| Stainless Steel Vacuum Chamber | Provides a durable, non-reactive environment under high vacuum to eliminate contaminants. |

| Vertical Orientation and Bottom Loading | Uses gravity for uniform gas flow and ergonomic, safe substrate handling. |

| Gas Delivery and Exhaust Systems | Regulates precursor gas flow and safely vents byproducts for controlled film composition and thickness. |

Ready to elevate your thin film deposition with a customized CVD furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including CVD/PECVD Systems, tailored for electronics, durable coatings, and materials research. Our strong deep customization capability ensures your unique experimental requirements are met precisely. Contact us today to discuss how our expertise can drive your innovations forward!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility