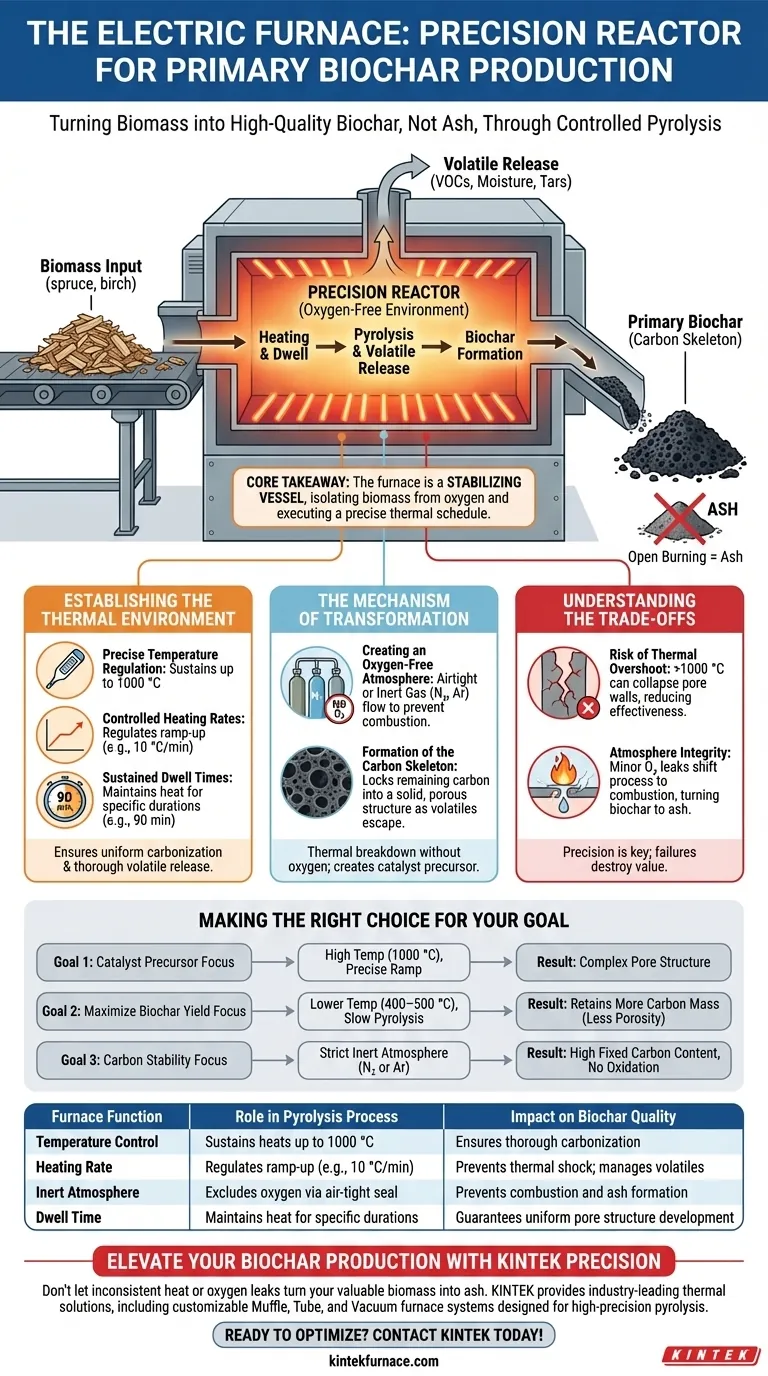

An electric heating industrial furnace serves as the precision reactor responsible for driving the thermochemical decomposition of biomass. Unlike open burning, this equipment creates a strictly controlled, oxygen-free environment that allows raw material—such as spruce or birch wood chips—to be converted into high-quality primary biochar rather than ash.

Core Takeaway The furnace functions not just as a heat source, but as a stabilizing vessel that isolates biomass from oxygen while executing a precise thermal schedule. By maintaining specific heating rates and dwell times (e.g., 1000 °C for 90 minutes), it ensures the thorough release of volatiles to leave behind a stable, porous carbonaceous skeleton.

Establishing the Thermal Environment

Precise Temperature Regulation

The primary role of the furnace is to reach and sustain high temperatures with exacting stability. For primary biochar production, the furnace must often maintain temperatures as high as 1000 °C.

Controlled Heating Rates

Success depends on how the target temperature is reached, not just the final heat level. The furnace regulates the ramp-up speed, such as a rate of 10 °C/min. This controlled acceleration prevents thermal shock and manages the predictable release of volatile components.

Sustained Dwell Times

Once the target temperature is achieved, the furnace maintains it for a set duration, typically around 90 minutes for specific wood chips. This "holding time" ensures the thermal energy penetrates the biomass completely, guaranteeing uniform carbonization throughout the material.

The Mechanism of Transformation

Creating an Oxygen-Free Atmosphere

The furnace is designed to be air-tight or to facilitate the flow of inert gases like nitrogen or argon. By excluding oxygen, the furnace prevents the biomass from combusting (burning away). Instead, it forces the material to undergo pyrolysis, where chemical bonds break down thermally rather than oxidatively.

Volatile Component Release

Under these high-temperature conditions, the furnace drives out non-carbon elements. It facilitates the removal of volatile organic compounds, moisture, and tars from the biomass matrix.

Formation of the Carbon Skeleton

As volatiles escape, the furnace locks the remaining carbon into a solid structure. This process results in a "carbonaceous catalyst precursor"—a material with a specific, preliminary pore structure that serves as the physical foundation for any future activation or filtration applications.

Understanding the Trade-offs

The Risk of Thermal Overshoot

While high temperatures (1000 °C) create a highly developed carbon structure, excessive heat or uncontrolled spikes can collapse the pore walls. This destroys the surface area intended for catalytic or adsorption activities, rendering the biochar less effective.

Atmosphere Integrity

The most common failure point is a breach in the furnace's sealed environment. Even a minor leak of oxygen during the high-heat phase will instantly shift the process from pyrolysis to combustion, turning valuable biochar into useless ash and significantly reducing yield.

Making the Right Choice for Your Goal

To select the correct furnace parameters for your specific biomass application, consider your end-goal requirements:

- If your primary focus is creating a catalyst precursor: Prioritize a furnace capable of higher temperatures (1000 °C) and precise ramp rates to develop a complex pore structure.

- If your primary focus is maximizing biochar yield: Utilize lower temperature settings (400–500 °C) to facilitate slow pyrolysis, which retains more carbon mass but develops less porosity.

- If your primary focus is carbon stability: Ensure the furnace can maintain a strict inert atmosphere (nitrogen or argon) to prevent oxidation and ensure the fixed carbon content is high.

Ultimately, the electric heating furnace acts as the gatekeeper of quality, determining whether your biomass becomes a high-value industrial material or simple waste ash.

Summary Table:

| Furnace Function | Role in Pyrolysis Process | Impact on Biochar Quality |

|---|---|---|

| Temperature Control | Sustains heats up to 1000 °C | Ensures thorough carbonization |

| Heating Rate | Regulates ramp-up (e.g., 10 °C/min) | Prevents thermal shock; manages volatiles |

| Inert Atmosphere | Excludes oxygen via air-tight seal | Prevents combustion and ash formation |

| Dwell Time | Maintains heat for specific durations | Guarantees uniform pore structure development |

Elevate Your Biochar Production with KINTEK Precision

Don't let inconsistent heat or oxygen leaks turn your valuable biomass into ash. KINTEK provides industry-leading thermal solutions, including customizable Muffle, Tube, and Vacuum furnace systems specifically designed for high-precision pyrolysis.

Backed by expert R&D and manufacturing, our systems offer the exact temperature regulation and atmosphere control needed to develop stable, porous carbon skeletons for any research or industrial application.

Ready to optimize your carbonization process? Contact KINTEK today to discuss your unique needs!

Visual Guide

References

- Roger Khalil, Øyvind Skreiberg. Catalytic Methane Decomposition for the Simultaneous Production of Hydrogen and Low-Reactivity Biocarbon for the Metallurgic Industry. DOI: 10.3390/en18030558

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- Why is an in-situ heating building plate integrated for IN718 alloys? Ensure Structural Integrity in AM

- What are the advantages of PVD equipment for solar absorber films? Achieve Nanometer Precision and Maximum Efficiency

- What is the function of a solvothermal reactor during Ir-TiO2 synthesis? Enhance Material Doping and Morphology

- What are the primary applications of a high-precision electric furnace in biomass characterization? Unlock Key Insights

- What are the advantages of using electron bombardment heating systems for Niobium? Achieve Industrial Fidelity

- How does a high-temperature laboratory furnace facilitate the pressureless sintering (PLS) of silicon nitride ceramics?

- What is the importance of a stable thermal environment during crystallization? Ensure Precision in Metal Oxide Films