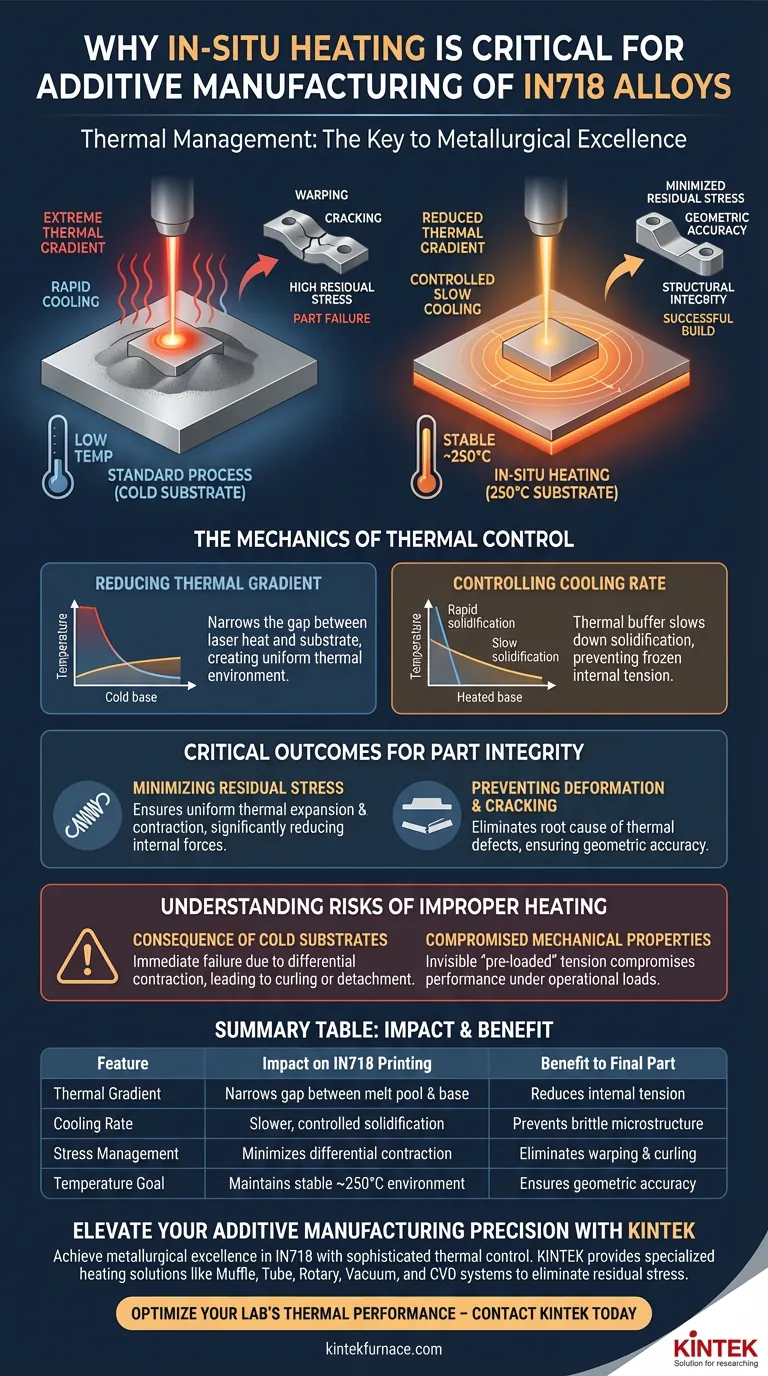

Thermal management is the critical factor in the successful additive manufacturing of superalloys like IN718. An in-situ heating building plate is integrated to maintain a stable, elevated environment—typically around 250°C—throughout the printing process. This intervention is necessary to counteract the extreme physics of laser melting, serving as a primary defense against structural failure.

Core Insight By sustaining a constant elevated temperature, the heating plate significantly reduces the thermal gradient between the intense heat of the laser melt pool and the substrate. This slows the cooling rate, which minimizes residual stress and effectively prevents the deformation and cracking that otherwise plague IN718 parts.

The Mechanics of Thermal Control

Reducing the Thermal Gradient

In standard additive manufacturing, a high-energy laser melts powder on top of a solid substrate. If the substrate is cold, the temperature difference (gradient) between the melt pool and the base is extreme.

An in-situ heating plate mitigates this by raising the baseline temperature of the foundation to approximately 250°C. This narrows the gap between the molten material and the solid material beneath it, creating a more uniform thermal environment.

Controlling the Cooling Rate

The speed at which metal solidifies and cools dictates its internal structure.

When the temperature gradient is high, heat dissipates too quickly, causing rapid solidification. The heated building plate acts as a thermal buffer, slowing down this cooling rate. This controlled cooling allows the material to settle more naturally, rather than being "frozen" in a state of high tension.

Critical Outcomes for Part Integrity

Minimizing Residual Stress

Residual stress is the internal tension locked into a part caused by uneven thermal expansion and contraction.

As layers are added, the heating plate ensures that the expansion and contraction occur more uniformly across the part. By preventing drastic temperature swings, the internal forces that usually build up during the printing process are significantly reduced.

Preventing Deformation and Cracking

When residual stress exceeds the strength of the material, the part fails.

In IN718 alloys, this often manifests as thermal deformation (warping or curling) or cracking (fractures within the layers). The heating plate eliminates the root cause of these defects by ensuring the material remains stress-relieved during the build, resulting in geometrically accurate and structurally sound components.

Understanding the Risks of Improper Heating

The Consequence of Cold Substrates

Attempting to print IN718 without an in-situ heating source often results in immediate part failure.

The bottom layers, in contact with a cold plate, contract rapidly while new hot layers are added on top. This differential contraction causes the part to curl upward at the edges, potentially detaching from the build plate entirely.

Compromised Mechanical Properties

Even if a part prints successfully on a cold plate, it may harbor invisible defects.

High residual stresses act as "pre-loaded" tension within the metal. This compromises the mechanical performance of the final component, making it liable to fail prematurely when subjected to operational loads.

Making the Right Choice for Your Goal

To ensure the success of your IN718 additive manufacturing projects, consider these priorities:

- If your primary focus is Structural Integrity: You must utilize in-situ heating to minimize internal residual stresses that lead to microscopic cracking.

- If your primary focus is Geometric Accuracy: You must maintain the 250°C substrate temperature to prevent thermal deformation and warping during the build.

Ultimately, the in-situ heating plate is not merely an accessory, but a fundamental requirement for achieving metallurgical soundness in additively manufactured IN718 components.

Summary Table:

| Feature | Impact on IN718 Printing | Benefit to Final Part |

|---|---|---|

| Thermal Gradient | Narrows gap between melt pool & base | Reduces internal tension |

| Cooling Rate | Slower, controlled solidification | Prevents brittle microstructure |

| Stress Management | Minimizes differential contraction | Eliminates warping & curling |

| Temperature Goal | Maintains stable ~250°C environment | Ensures geometric accuracy |

Elevate Your Additive Manufacturing Precision with KINTEK

Achieving metallurgical excellence in IN718 requires more than just high-energy lasers; it demands sophisticated thermal control. Backed by expert R&D and world-class manufacturing, KINTEK provides the specialized heating solutions and high-temperature systems necessary to eliminate residual stress and prevent part failure.

Whether you need customizable Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab furnaces are engineered to meet the unique thermal management needs of advanced additive manufacturing. Don't let thermal deformation compromise your innovation.

Optimize Your Lab's Thermal Performance — Contact KINTEK Today

Visual Guide

References

- Lakshmi Ramineni, Ala Qattawi. Residual Stress Mapping in Heat-Assisted Additive Manufacturing of IN 718: An X-Ray Diffraction Study. DOI: 10.1007/s11665-024-09269-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the technical advantages of using the molten salt method? Elevate Your Biomass Carbon Support Synthesis

- What critical environment does a high-temp furnace provide for H13 steel? Mastering Microstructural Homogenization

- What are the three steps parts go through in a conveyor furnace? Master Sintering for Stronger Parts

- What is the function of a stable heating environment and ethylene glycol in gold nanoparticle synthesis? Achieve Precision

- What is the mechanism of the thermal reduction process for graphene oxide-cement? Master Thermal Activation in Furnaces

- Why are batch furnaces considered essential for certain applications? Achieve Precision and Flexibility in Heat Treatment

- Why are precision hydrothermal reactors necessary for nut shell modification? Unlock Biomass Energy Potential

- How do chill rings specifically influence the temperature field distribution? Expert Insight into Crystal Casting