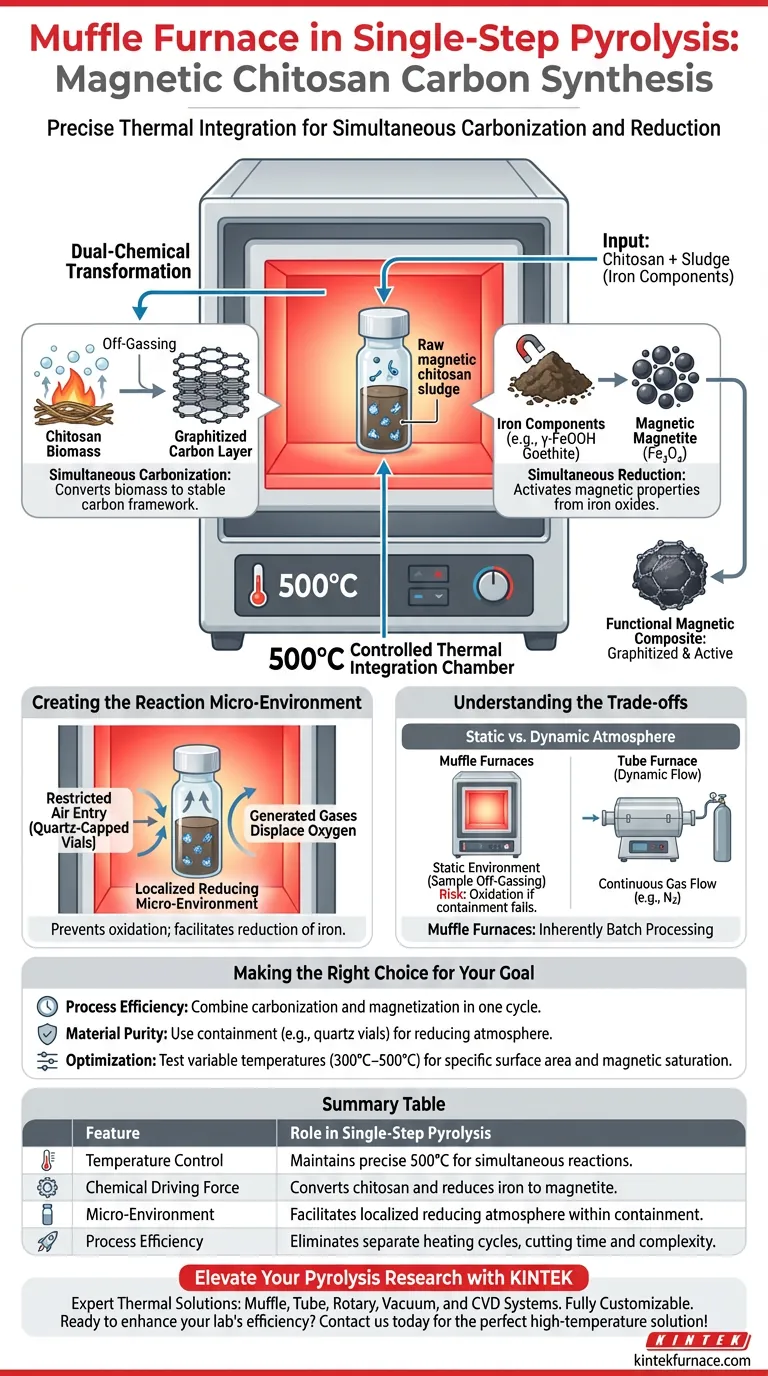

The muffle furnace serves as the precise thermal integration chamber required to execute the single-step pyrolysis of magnetic chitosan carbon.

It functions not merely as a heater, but as a controlled reactor that drives two distinct chemical processes simultaneously. By maintaining a constant calcination temperature of 500°C, the furnace enables the carbonization of the organic chitosan while concurrently forcing the chemical reduction of iron components found in the sludge. This synchronicity allows for the creation of a composite material that is both graphitized and magnetically active without the need for multiple processing stages.

Core Takeaway The muffle furnace’s critical value lies in its ability to maintain a thermal environment that supports simultaneous reaction mechanisms. It facilitates the decomposition of biomass into a carbon framework while reducing iron oxides into magnetite in a single, integrated workflow, effectively cutting process time and complexity.

The Dual-Chemical Transformation

Simultaneous Carbonization and Reduction

The primary role of the muffle furnace is to provide the energy required to break down complex organic structures.

At a controlled temperature of 500°C, the furnace decomposes the chitosan. This thermal breakdown converts the raw biomass into a stable, graphitized carbon layer.

Activation of Magnetic Properties

While the carbon structure forms, the furnace’s heat drives a specific phase transformation in the iron components.

The thermal energy induces the reduction of goethite ($\gamma$-FeOOH) present in the sludge. This reaction converts the non-magnetic goethite into magnetic magnetite ($Fe_3O_4$). This ensures the final product is not just a carbon shell, but a functional magnetic composite.

The Significance of the Single Step

In standard processing, carbonization and magnetization might require separate kilns or heating cycles.

The muffle furnace allows these reactions to occur in a "single integrated step." By carefully managing the heating rate and hold time, the furnace ensures that the formation of the carbon matrix and the crystallization of the magnetite happen in unison.

Creating the Reaction Micro-Environment

Managing Oxidation Risks

A standard muffle furnace often contains ambient air, which would typically burn (oxidize) biomass rather than carbonize it.

To prevent this, the process often utilizes containment strategies, such as quartz-capped vials. These vials act as micro-reaction chambers inside the furnace, restricting the entry of external air.

The Role of Generated Gases

As the furnace heats the chitosan, the biomass releases gases during decomposition.

Because of the restricted environment (like the quartz vials), these gases create a localized reducing micro-environment. This displaces oxygen and prevents the carbon framework from burning away, while chemically assisting the reduction of iron into its magnetic phase.

Understanding the Trade-offs

Static vs. Dynamic Atmosphere

A standard box-type muffle furnace provides a static thermal environment.

Unlike tube furnaces which allow for continuous gas flow (like Nitrogen or Argon), a muffle furnace typically relies on the sample's own off-gassing to create an oxygen-free zone. If the containment (e.g., the vial cap) fails, the sample will oxidize (burn to ash) rather than pyrolyze.

Batch Processing Limitations

Muffle furnaces are inherently designed for batch processing.

While excellent for establishing optimal residence times and temperature gradients (e.g., 250°C to 500°C) for research, they are less suited for continuous, high-throughput manufacturing compared to rotary kilns or conveyor furnaces.

Making the Right Choice for Your Goal

- If your primary focus is Process Efficiency: Utilize the muffle furnace to combine carbonization and magnetization into one cycle, eliminating the need for pre-calcination steps.

- If your primary focus is Material Purity: Ensure you utilize a containment method (like quartz vials) within the furnace to create the necessary reducing atmosphere and prevent oxidation of the carbon backbone.

- If your primary focus is Optimization: Use the muffle furnace to test variable temperatures (300°C–500°C) to find the exact point where specific surface area and magnetic saturation are maximized.

The muffle furnace is the tool that transforms a complex, multi-stage chemical synthesis into a manageable, one-step thermal reaction.

Summary Table:

| Feature | Role in Single-Step Pyrolysis |

|---|---|

| Temperature Control | Maintains precise 500°C for simultaneous carbonization and reduction. |

| Chemical Driving Force | Converts chitosan to graphitized carbon while reducing iron to magnetite. |

| Micro-Environment | Facilitates a localized reducing atmosphere within containment vials. |

| Process Efficiency | Eliminates the need for separate heating cycles, cutting time and complexity. |

Elevate Your Pyrolysis Research with KINTEK

Are you looking to optimize your single-step synthesis or material graphitization? KINTEK provides the precision thermal solutions required for complex chemical transformations.

Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific lab requirements. Whether you need precise atmospheric control or specific heating gradients, our furnaces are engineered to deliver consistent, high-purity results.

Ready to enhance your lab's efficiency? Contact us today to find the perfect high-temperature solution for your unique research needs!

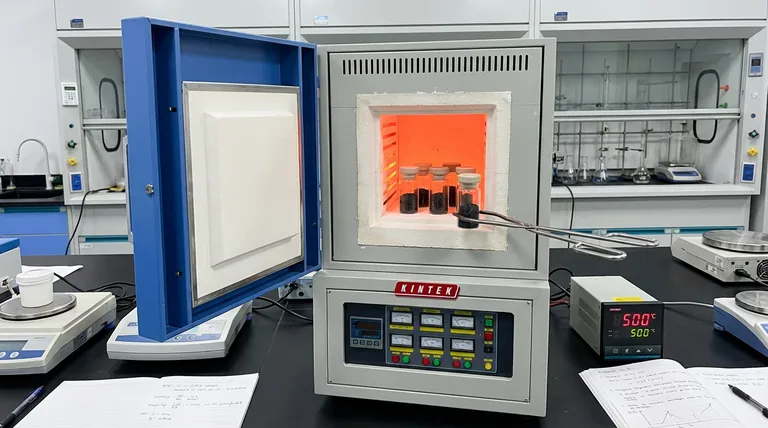

Visual Guide

References

- Huiping Zeng, Dong Li. Facile Preparation of Magnetic Chitosan Carbon Based on Recycling of Iron Sludge for Sb(III) Removal. DOI: 10.3390/su16072788

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a high-temperature box furnace contribute to the sintering of doped zirconate ceramics? Achieve 94% Density

- Why is the use of a Muffle Furnace critical during the calcination stage of TiO2/g-C3N4? Master Composite Synthesis

- What is the typical function of a laboratory muffle furnace in the preparation of chemical catalysts? | KINTEK

- What atmosphere control options are available in advanced muffle furnaces? Master Materials Processing with Precision

- How are Box Furnaces typically loaded? Manual Methods for Flexible Batch Processing

- What role does a laboratory high-temperature box furnace play in fire impact experiments for steel? | KINTEK

- What precautions should be taken when melting samples with alkaline substances? Safeguard Your Furnace from Corrosion

- What precautions should be taken with the thermostat before an experiment? Ensure Accuracy and Safety in Your Lab