In short, box furnaces are almost always loaded manually, often with the help of common material handling equipment. This straightforward approach involves operators using tools like forklifts to place large parts or roller hearths to slide in trays of smaller components.

The defining characteristic of a box furnace is its suitability for batch processing. Its manual loading method reflects this design philosophy, prioritizing operational flexibility and simplicity over the high-volume throughput of continuous, automated systems.

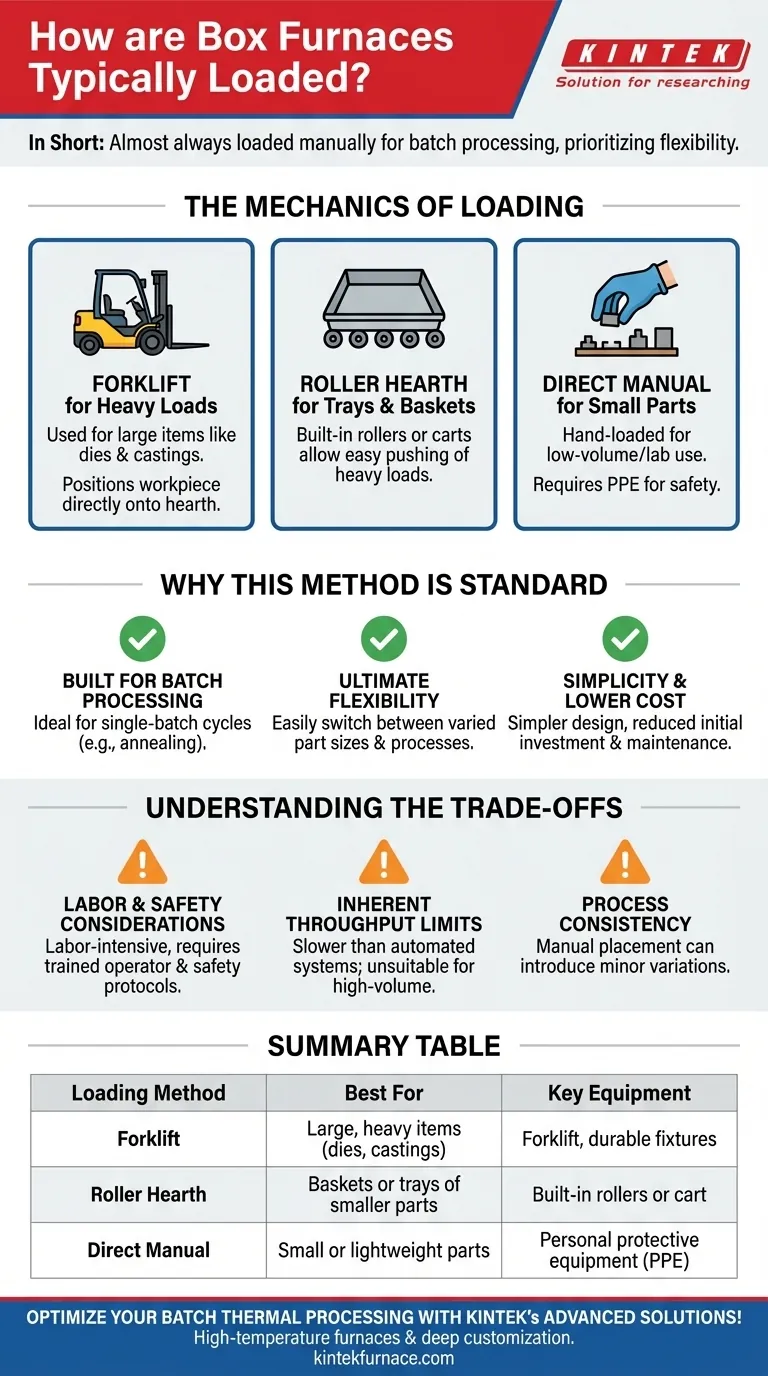

The Mechanics of Loading a Box Furnace

Understanding how a box furnace is loaded reveals its core operational purpose. The process is straightforward and relies on direct operator involvement, making it adaptable to a wide range of parts and processes.

Using Forklifts for Heavy Loads

For large, heavy items like dies, castings, or sizable fabrications, a forklift is the most common loading tool. The operator carefully positions the workpiece directly onto the furnace hearth or onto durable fixtures placed inside. This method is simple, robust, and leverages equipment already present in most industrial facilities.

Employing Roller Hearths for Efficiency

When processing baskets or trays of smaller parts, a roller hearth can be used. These are sets of rollers, either built into the furnace entrance or on a separate cart, that allow an operator to easily push a heavy load into the heating chamber with minimal physical effort.

Direct Manual Placement

For very small or lightweight parts, an operator may load them by hand. This is common in laboratory settings or for specialized, low-volume applications. This always requires appropriate personal protective equipment (PPE) to protect against the furnace's residual heat.

Why This Method is Standard

The manual loading process isn't an incidental feature; it's fundamental to the box furnace's role in thermal processing. It is a direct consequence of its design for batch-based work.

Built for Batch Processing

A box furnace is designed to process one discrete batch of material at a time. This is ideal for applications like annealing, stress relief, or preheating, where a specific set of parts undergoes a complete thermal cycle before the next batch is introduced. Manual loading is the most logical and cost-effective method for this workflow.

Ultimate Flexibility

Manual loading provides unparalleled versatility. Operators can easily switch between processing a single large component in one cycle and a basket of hundreds of small parts in the next. This adaptability is crucial for job shops or R&D environments where production runs are varied and unpredictable.

Simplicity and Lower Cost

Automated loading and unloading systems are complex and expensive. The manual approach keeps the furnace's design simple, reducing initial capital investment, lowering maintenance costs, and minimizing potential points of failure.

Understanding the Trade-offs

While simple and flexible, the manual loading method has clear limitations that you must consider for your operation.

Labor and Safety Considerations

This method is labor-intensive. It requires a trained operator to be present for loading and unloading, which impacts labor costs. It also introduces safety considerations related to handling heavy items and interacting with high-temperature equipment.

Inherent Throughput Limits

Manual loading is the primary bottleneck for a box furnace's productivity. The process is inherently slower than an automated, continuous system, making it unsuitable for high-volume, repetitive manufacturing where cycle time is critical.

Process Consistency

While generally reliable, manual placement can introduce slight variations in how parts are arranged within the furnace. This can potentially lead to minor inconsistencies in heat exposure compared to a perfectly repeatable robotic system.

Making the Right Choice for Your Process

The suitability of a box furnace's loading method depends entirely on your production goals.

- If your primary focus is flexibility for varied parts and processes: The manual loading of a box furnace is ideal for batch-oriented workflows like annealing, curing, or die preheating.

- If your primary focus is high-volume, uniform production: You should explore continuous furnace types, as the batch-and-load nature of a box furnace will not meet your throughput needs.

Ultimately, choosing a box furnace means embracing a flexible, batch-oriented process where adaptability is valued over automated speed.

Summary Table:

| Loading Method | Best For | Key Equipment |

|---|---|---|

| Forklift | Large, heavy items (e.g., dies, castings) | Forklift, durable fixtures |

| Roller Hearth | Baskets or trays of smaller parts | Built-in rollers or cart |

| Direct Manual | Small or lightweight parts | Personal protective equipment (PPE) |

Optimize your batch thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Box, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance flexibility and efficiency in your operations!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance