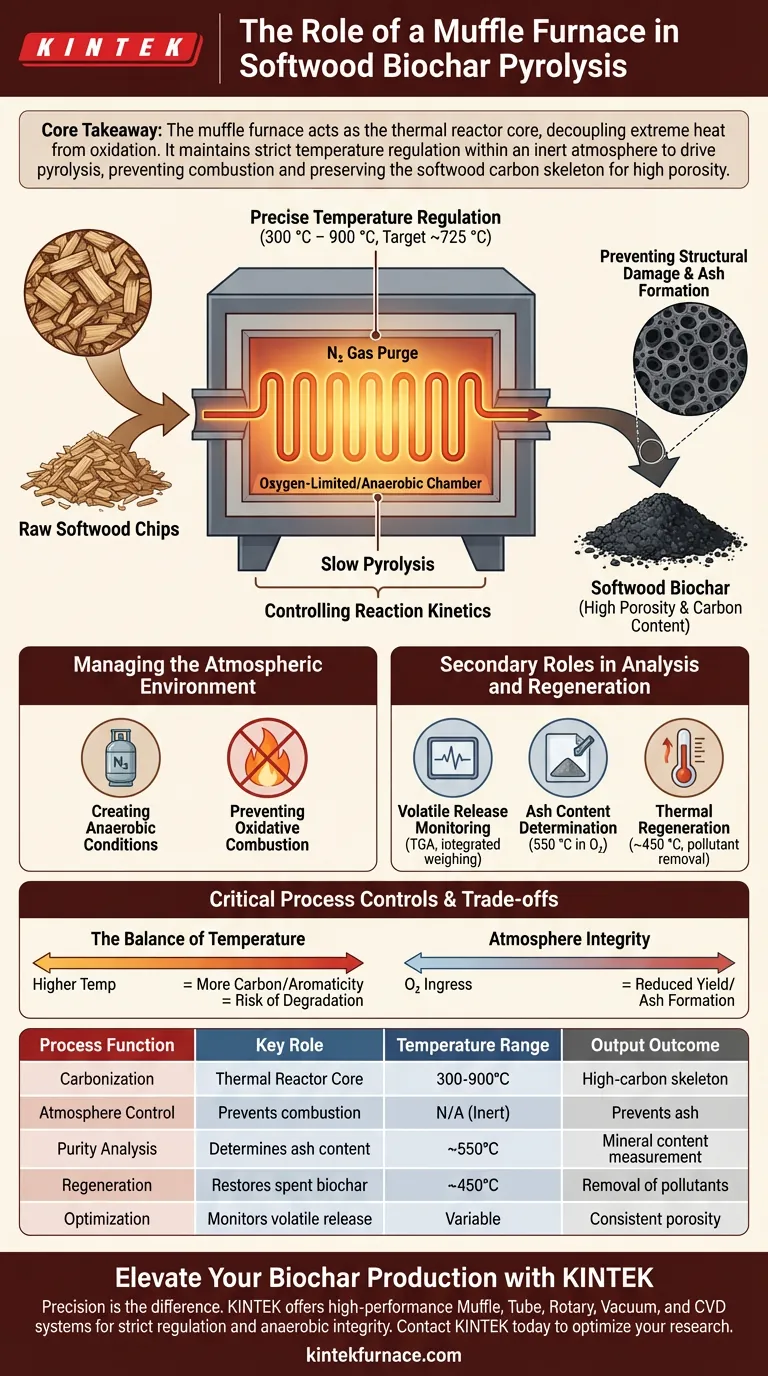

The muffle furnace serves as the thermal reactor core in the production of softwood biochar. It creates a precisely controlled, high-temperature environment—often targeting specific set points like 725 °C—to initiate carbonization. By isolating the softwood biomass in an oxygen-limited or anaerobic chamber, the furnace drives pyrolysis rather than combustion, transforming the raw material into a stable biochar defined by high porosity and carbon content.

Core Takeaway The muffle furnace’s primary value lies in its ability to decouple extreme heat from oxidation. By maintaining strict temperature regulation within an inert atmosphere, it prevents the softwood from burning to ash, instead preserving the carbon skeleton to engineer a highly porous material.

The Mechanics of Thermal Transformation

Precise Temperature Regulation

The fundamental role of the muffle furnace is to maintain exact temperatures, typically ranging from 300 °C to 900 °C depending on the specific pyrolysis goals. For softwood specifically, temperatures around 725 °C are often utilized to maximize carbonization.

Controlling Reaction Kinetics

Industrial-grade furnaces ensure the biomass is heated evenly to trigger specific decomposition reactions. This regulation is critical because temperature determines the resulting surface area, pore volume, and aromaticity of the biochar.

Preventing Structural Damage

If temperatures spike uncontrollably, the carbon skeleton of the softwood can crack or collapse. The muffle furnace prevents this overheating, ensuring the physical structure remains intact to provide ideal adsorption activity.

Managing the Atmospheric Environment

Creating Anaerobic Conditions

To achieve pyrolysis, the furnace must exclude oxygen. This is often achieved by continuously purging the reactor with nitrogen gas or utilizing a vacuum system.

Preventing Oxidative Combustion

Without this atmospheric control, the high heat would cause the softwood to simply burn (oxidative combustion), leaving behind mineral ash rather than carbon. The muffle furnace facilitates slow pyrolysis, which is essential for developing a rich porous structure.

Secondary Roles in Analysis and Regeneration

Volatile Release Monitoring

Advanced muffle furnaces equipped with integrated weighing systems allow for thermogravimetric analysis (TGA). This enables researchers to monitor mass changes in real-time, identifying the exact moment volatile components are released and optimizing the holding time for consistent quality.

Ash Content Determination

Beyond production, the furnace is used to analyze purity by heating samples to 550 °C in an oxygen-rich environment. This completely combusts organic matter, allowing operators to measure the residual mineral (inorganic) content and evaluate its influence on adsorption performance.

Thermal Regeneration

The furnace also plays a role in the lifecycle management of biochar. By heating spent biochar to approximately 450 °C, the furnace can thermally decompose organic pollutants adsorbed within the pores, restoring the material's utility for water treatment applications.

Critical Process Controls and Trade-offs

The Balance of Temperature

Higher temperatures generally increase carbon content but can alter pore structure. Operating at the higher end of the spectrum (e.g., near 900 °C) increases aromaticity but requires strict control to prevent the degradation of the material's adsorptive properties.

Atmosphere Integrity

The most common point of failure is a breach in the anaerobic environment. Even a small amount of oxygen ingress during the high-temperature phase can significantly reduce the yield of biochar and increase the production of unwanted ash.

Making the Right Choice for Your Goal

- If your primary focus is maximizing porosity: Prioritize a furnace setup with robust nitrogen purging capable of sustaining slow pyrolysis between 500 °C and 800 °C.

- If your primary focus is purity analysis: Utilize the furnace for total combustion at 550 °C to isolate and measure inorganic mineral content.

- If your primary focus is process optimization: Select a unit with integrated weighing capabilities to precisely map volatile release kinetics and determine optimal residence times.

Precise thermal management is the single most important factor in converting raw softwood into a high-performance industrial carbon material.

Summary Table:

| Process Function | Key Role | Temperature Range | Output Outcome |

|---|---|---|---|

| Carbonization | Acts as the thermal reactor core | 300°C – 900°C | High-carbon skeleton |

| Atmosphere Control | Prevents oxidative combustion | N/A (Inert/Vacuum) | Prevents ash formation |

| Purity Analysis | Determines ash content | ~550°C | Mineral content measurement |

| Regeneration | Restores spent biochar | ~450°C | Removal of adsorbed pollutants |

| Optimization | Monitors volatile release | Variable | Consistent porosity & surface area |

Elevate Your Biochar Production with KINTEK

Precision is the difference between high-quality biochar and simple ash. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the strict temperature regulation and anaerobic integrity your research demands.

Whether you need customizable lab furnaces for softwood pyrolysis or specialized equipment for thermal regeneration, our systems ensure your materials achieve peak porosity and carbon content. Contact KINTEK today to discuss your unique project needs and discover how our advanced thermal solutions can optimize your laboratory results.

Visual Guide

References

- Mohammad Umair Jamal, Lidija Šiller. Scottish softwood biochar for water remediation targeting selected persistent organic pollutants. DOI: 10.1177/02636174241256854

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the main uses of a muffle furnace? Unlock Precise High-Temp Processing for Your Lab

- What are the key components of a muffle furnace? Uncover the Core Parts for Precise High-Temperature Control

- What specialized processes utilize box furnaces? Discover Versatile Heat Treatment Solutions

- Why might crucible furnaces be inefficient? High Operating Costs from Low Thermal Efficiency

- How does a high-temperature muffle furnace facilitate the formation of the Sr2TiO4 semiconductor structure?

- What is the mechanism for the furnace door in a muffle furnace? Discover the Double-Hinge Design for Perfect Sealing

- What is the function of a high-temperature muffle furnace in LATP pre-calcination? Essential Solid-Phase Reactions

- What are the steps for setting up a muffle furnace before use? Ensure Safety and Accuracy in Your Lab