At its core, a muffle furnace is a high-temperature oven designed for clean, controlled heating. Its primary uses fall into three main categories: analytical testing to determine a material's composition, heat treatment to alter a material's physical properties, and the synthesis of new materials through processes like sintering and firing.

The defining feature of a muffle furnace is not just its high heat, but its internal chamber—the "muffle"—which isolates the sample from the heating elements. This prevents contamination and ensures the sample is heated uniformly by radiant and convective heat alone.

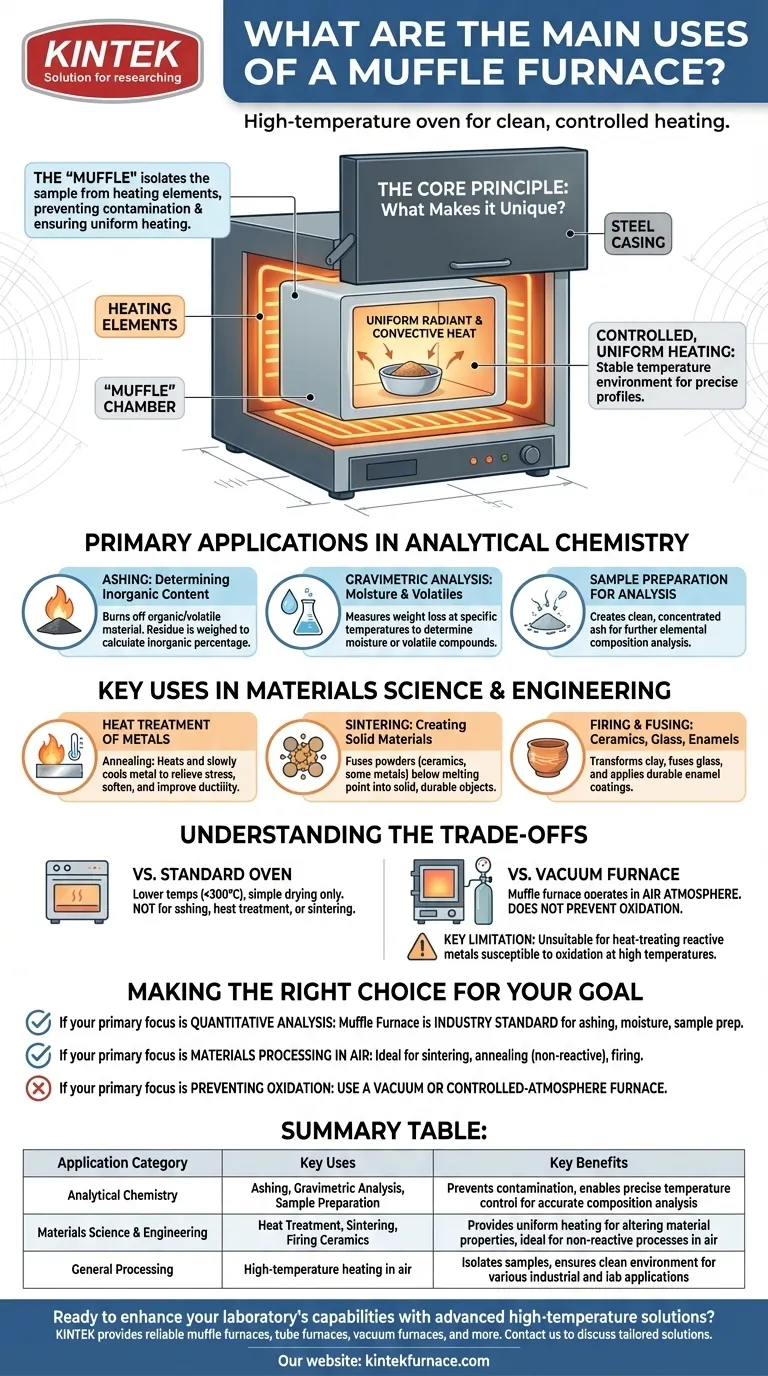

The Core Principle: What Makes a Muffle Furnace Unique?

A muffle furnace is fundamentally different from a simple high-temperature oven because of its construction, which is purpose-built for specific types of processing.

The "Muffle": Isolating the Sample

The term "muffle" refers to the sealed inner chamber that holds the sample. This chamber is heated from the outside by heating elements.

This design prevents any byproducts of combustion or material flaking from the heating elements from contaminating the sample. It ensures the integrity of analytical results and material processing.

Controlled, Uniform Heating

By heating the entire muffle chamber, the furnace provides an extremely stable and uniform temperature environment. This is critical for processes that require precise temperature profiles, such as annealing metals or performing gravimetric analysis.

Primary Applications in Analytical Chemistry

In laboratory settings, muffle furnaces are indispensable tools for preparing samples and determining their fundamental composition.

Ashing: Determining Inorganic Content

Ashing is the most common analytical use. The furnace is used to burn off all organic and volatile material from a sample at high temperatures.

What remains is the non-combustible ash (inorganic residue). By weighing the sample before and after ashing, analysts can accurately determine the percentage of inorganic content in materials like food, soil, plastics, and pharmaceuticals.

Gravimetric Analysis: Moisture and Volatiles

By heating a sample to a specific temperature (e.g., 105°C) and measuring the weight loss, a muffle furnace can be used for moisture determination.

At higher temperatures, it can also measure the amount of volatile matter, which are compounds that vaporize when heated but are not part of the moisture content.

Sample Preparation for Analysis

Often, ashing is just the first step. The resulting ash is a clean, concentrated sample of the material's inorganic elements, which can then be dissolved and analyzed further using more advanced techniques to determine its exact elemental composition.

Key Uses in Materials Science and Engineering

Muffle furnaces are used to create, refine, and test materials where high heat is required to change their physical or chemical properties.

Heat Treatment of Metals

Processes like annealing involve heating a metal to a specific temperature and then cooling it slowly. This relieves internal stresses, softens the metal, and improves its ductility. Muffle furnaces provide the precise temperature control needed for this.

Sintering: Creating Solid Materials

Sintering is a process used to create solid objects from powders, most commonly with ceramics and some metals. The furnace heats the material to just below its melting point, causing the particles to fuse together into a solid, durable mass.

Firing and Fusing: Ceramics, Glass, and Enamels

A muffle furnace is used to fire ceramics and pottery, transforming clay into a hard, permanent state. It is also used for fusing glass pieces together in art applications and for creating durable enamel coatings on metal.

Understanding the Trade-offs

Choosing a muffle furnace means understanding its specific strengths and limitations compared to other heating equipment.

Muffle Furnace vs. a Standard Oven

Standard laboratory ovens operate at much lower temperatures (typically below 300°C) and lack the insulated muffle chamber. They are suitable for simple drying but not for ashing, heat treatment, or sintering.

Muffle Furnace vs. a Vacuum Furnace

This is the most critical distinction. A muffle furnace operates in a normal air atmosphere. While the muffle prevents direct contamination, it does not prevent oxidation or other reactions with the air.

If a process requires heating a material without it reacting with oxygen, a vacuum furnace or a tube furnace with a controlled inert gas (like argon or nitrogen) is required.

Key Limitation: Atmospheric Reactions

The primary limitation of a muffle furnace is that all processes occur in the presence of air. This makes it unsuitable for heat-treating reactive metals that would be damaged by oxidation at high temperatures.

Making the Right Choice for Your Goal

To select the correct process, you must first define your goal: are you analyzing, processing, or trying to prevent a specific chemical reaction?

- If your primary focus is quantitative analysis: A muffle furnace is the industry standard for ashing, moisture determination, and preparing samples for elemental analysis.

- If your primary focus is materials processing in air: It is ideal for sintering ceramics, annealing non-reactive metals, and firing glass or enamel where an air atmosphere is acceptable.

- If your primary focus is preventing oxidation: You must use a vacuum or controlled-atmosphere furnace, as a muffle furnace will not protect your sample from the air.

Understanding that a muffle furnace provides clean, high-temperature atmospheric heating is the key to leveraging it effectively for your specific application.

Summary Table:

| Application Category | Key Uses | Key Benefits |

|---|---|---|

| Analytical Chemistry | Ashing, Gravimetric Analysis, Sample Preparation | Prevents contamination, enables precise temperature control for accurate composition analysis |

| Materials Science & Engineering | Heat Treatment, Sintering, Firing Ceramics | Provides uniform heating for altering material properties, ideal for non-reactive processes in air |

| General Processing | High-temperature heating in air | Isolates samples, ensures clean environment for various industrial and lab applications |

Ready to enhance your laboratory's capabilities with advanced high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse labs with reliable muffle furnaces, tube furnaces, vacuum furnaces, and more. Our strong deep customization capability ensures we can precisely meet your unique experimental needs, from analytical testing to material synthesis. Contact us today to discuss how our tailored furnace solutions can drive your success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?