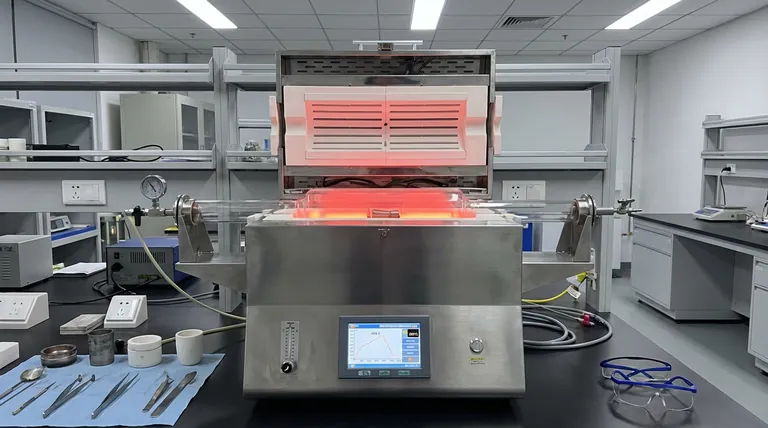

A laboratory tube furnace functions as the critical control environment for the post-sintering heat treatment of Nickel-Titanium-Copper (NiTiCu) alloys. It facilitates a precise two-step aging process, typically at 850°C and 500°C, to transform the raw sintered material into a functional alloy with optimized mechanical properties.

By governing heating rates, cooling rates, and holding times, the furnace provides the exact thermodynamic conditions required to precipitate internal phases like Ni3Ti and NiTi2. This process is essential for relieving sintering stresses and activating the alloy’s shape memory characteristics.

Precision Control of Thermal Parameters

To achieve the desired material properties in NiTiCu alloys, mere heating is insufficient; the specific thermal profile is paramount.

Two-Step Aging Protocols

The tube furnace allows for the execution of complex thermal cycles, specifically a two-step aging process. The primary reference highlights a protocol involving treatment at 850°C followed by a secondary stage at 500°C.

Regulating Heating and Cooling Rates

The furnace must support rapid and controlled temperature changes. For NiTiCu alloys, a heating and cooling rate of 100°C/min is often utilized.

Precise control over these rates prevents thermal shock while ensuring the material reaches the necessary temperature equilibrium efficiently.

Microstructural Engineering

The deep need addressed by the tube furnace is the manipulation of the alloy's internal microstructure. This is where the physical properties of the material are actually determined.

Precipitating Critical Phases

The thermal energy provided by the furnace drives the precipitation of specific internal phases, notably Ni3Ti and NiTi2.

The presence and distribution of these phases are what differentiate a high-performance shape memory alloy from a standard metal. The furnace creates the thermodynamic environment necessary for these chemical structural changes to occur.

Eliminating Internal Stresses

Sintering—the process of compacting and forming the alloy—leaves behind significant residual stresses.

The heat treatment process acts as a stress-relief mechanism. By maintaining specific temperatures, the furnace allows the microstructure to adjust, effectively eliminating sintering stresses that could otherwise lead to mechanical failure or poor performance.

Understanding the Trade-offs

While the tube furnace is a powerful tool, achieving the correct results requires managing specific variables and potential pitfalls.

The Risk of Incorrect Kinetics

The specific rates mentioned (e.g., 100°C/min) are not arbitrary. If the furnace cannot maintain these ramp rates, the precipitation kinetics will change.

Slow heating or cooling may result in phase sizes or distributions that do not support the desired shape memory effect.

Thermodynamic Sensitivity

The process relies on driving the material from a non-equilibrium state toward a desired equilibrium.

Fluctuations in the furnace's "hot zone" stability can lead to uneven microstructural evolution. This underscores the need for a furnace capable of maintaining a strictly uniform thermal field during the holding times.

Making the Right Choice for Your Goal

The specific settings you employ in the tube furnace should be dictated by the final properties you wish to engineer in the NiTiCu alloy.

- If your primary focus is Shape Memory Optimization: Prioritize the precise formation of Ni3Ti and NiTi2 phases by strictly adhering to the two-step aging temperatures (850°C and 500°C).

- If your primary focus is Structural Integrity: Focus on the holding times to ensure complete solid-state diffusion, which maximizes the elimination of residual sintering stresses.

- If your primary focus is Process Consistency: Ensure your furnace is calibrated to deliver exact ramp rates (e.g., 100°C/min), as deviations here will alter the fundamental precipitation kinetics.

The laboratory tube furnace is not just a heating element; it is the instrument that defines the life and performance of the alloy through rigorous thermodynamic control.

Summary Table:

| Parameter | Typical Setting | Function in NiTiCu Treatment |

|---|---|---|

| Aging Phase 1 | 850°C | Relieves sintering stresses & initiates diffusion |

| Aging Phase 2 | 500°C | Drives precipitation of Ni3Ti and NiTi2 phases |

| Thermal Ramp Rate | 100°C/min | Ensures optimal precipitation kinetics |

| Atmosphere Control | Controlled/Vacuum | Prevents oxidation during high-temp cycles |

Elevate Your Material Research with KINTEK

Precision is the difference between a standard metal and a high-performance shape memory alloy. KINTEK provides industry-leading laboratory tube furnaces designed to meet the rigorous demands of NiTiCu heat treatment.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific thermal profiles and ramp rate requirements. Whether you are optimizing phase precipitation or ensuring structural integrity, our high-temperature solutions deliver the thermodynamic stability you need.

Ready to achieve superior alloy performance? Contact KINTEK today to discuss your custom furnace needs.

References

- Diana C. Cirstea, Ernst Kozeschnik. Thermodynamic and Kinetic Simulations Used for the Study of the Influence of Precipitates on Thermophysical Properties in NiTiCu Alloys Obtained by Spark Plasma Sintering. DOI: 10.3390/nano14050461

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety