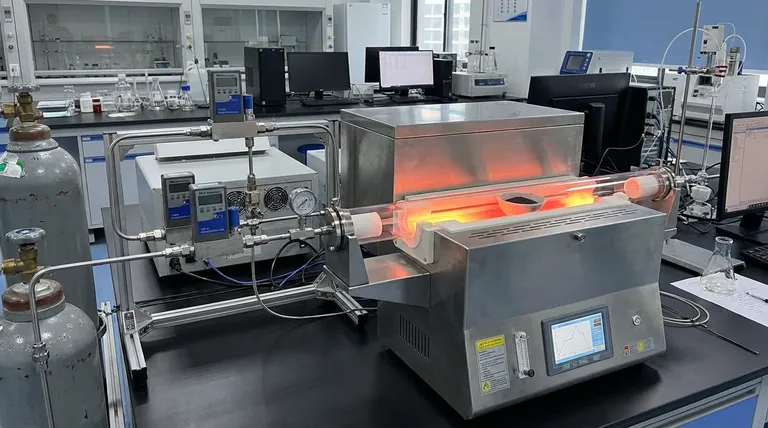

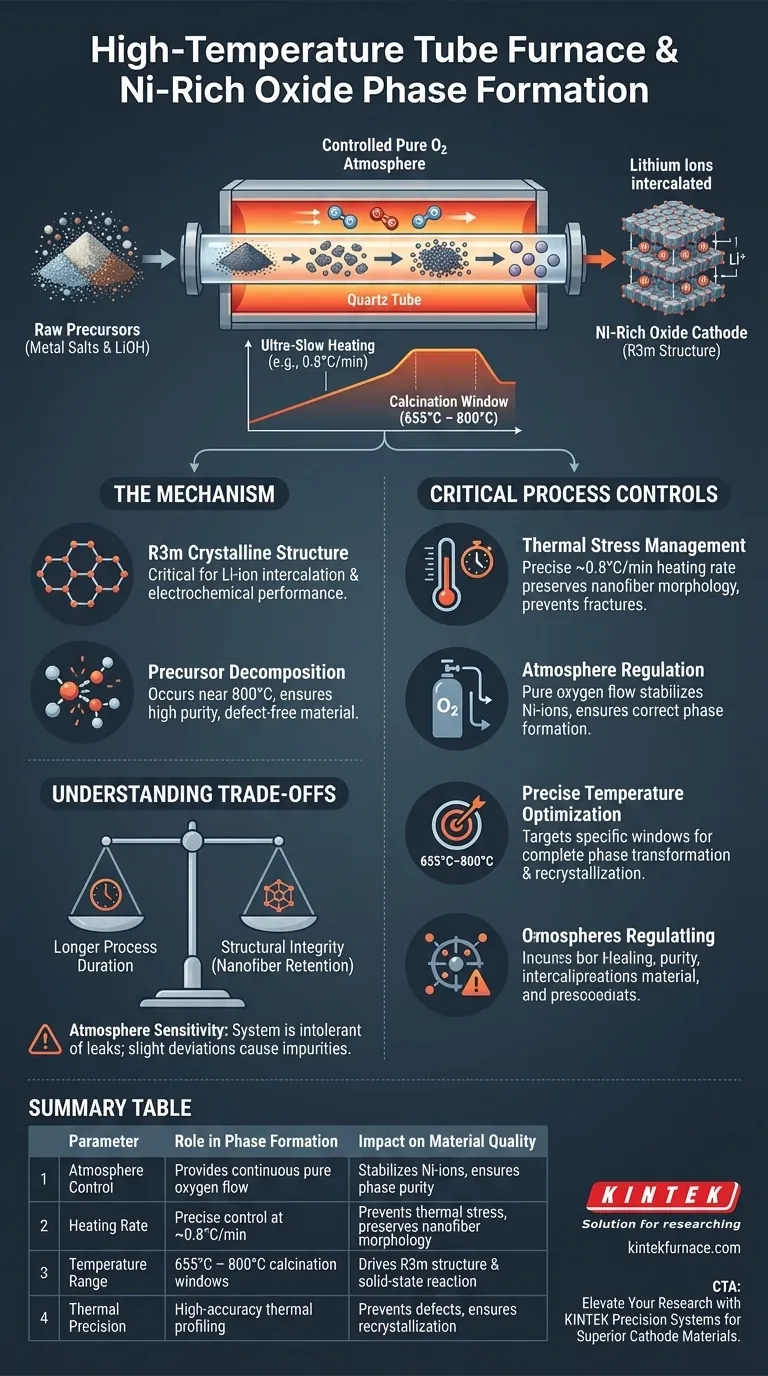

A laboratory high-temperature tube furnace serves as the primary vessel for orchestrating the precise thermal and atmospheric conditions required to synthesize Ni-rich oxide cathode materials. It enables the transformation of raw precursors into a stable crystalline structure by strictly controlling heating rates, maintaining a pure oxygen environment, and holding specific temperatures to drive phase formation.

By maintaining a continuous pure oxygen flow and executing ultra-slow heating rates (such as 0.8°C/min), the furnace facilitates the decomposition of precursors into a hexagonal layered R3m structure. This controlled environment is essential for preserving nanofiber morphology and preventing fractures caused by thermal stress.

The Mechanism of Phase Formation

Achieving the R3m Crystalline Structure

The primary role of the furnace is to drive the transition of materials into the R3m space group hexagonal layered structure.

This specific crystal arrangement is critical for the electrochemical performance of the cathode. The furnace facilitates the solid-state reaction between metal salt precursors and lithium hydroxide, allowing lithium ions to intercalate correctly into the crystal lattice.

Decomposition of Precursors

Before the final structure forms, the starting materials must undergo chemical decomposition.

At temperatures approaching 800°C, the tube furnace ensures that metal salt precursors break down completely. This step is the foundation for creating high-purity, single-phase materials free from structural defects.

Critical Process Controls

Management of Thermal Stress

One of the most vital functions of the tube furnace is the regulation of heating rates to protect the material's physical shape.

Rapid heating can cause the unique nanofiber morphology of these materials to fracture. By utilizing a precise, slow heating rate of 0.8°C/min, the furnace mitigates thermal stress, ensuring the material retains its structural integrity throughout the calcination process.

Atmosphere Regulation

Ni-rich oxides are highly sensitive to their environment during synthesis.

The tube furnace provides a pure oxygen atmosphere (or continuous oxygen flow field) necessary for the reaction. This oxygen-rich environment is mandatory to stabilize the nickel ions and ensure the formation of the correct oxide phases.

Precise Temperature Optimization

The furnace enables the user to target specific thermal windows to optimize the material's properties.

While decomposition often occurs near 800°C, optimized calcination processes may range between 655°C and 710°C depending on the specific composition. The furnace’s ability to hold these temperatures precisely ensures complete phase transformation and recrystallization.

Understanding the Trade-offs

Process Duration vs. Structural Integrity

The requirement for ultra-slow heating rates (e.g., 0.8°C/min) creates a significant trade-off in processing time.

To prevent fracturing the nanofiber morphology, researchers must accept much longer cycle times compared to standard sintering processes. Rushing this step almost invariably leads to structural degradation.

Sensitivity to Atmosphere Fluctuations

The reliance on a pure oxygen atmosphere means the system is intolerant of leaks or impure gas sources.

Even minor deviations in the oxygen flow field within the tube can lead to incomplete phase transformation or the formation of impurities on the cathode surface, compromising electrochemical performance.

Making the Right Choice for Your Goal

When configuring your thermal processing parameters for Ni-rich oxides, prioritize your settings based on the material's critical needs:

- If your primary focus is Morphology Retention: strictly adhere to the slow heating rate (0.8°C/min) to prevent thermal stress fractures in nanofiber structures.

- If your primary focus is Phase Purity: ensure the furnace maintains a continuous, pure oxygen flow to drive the complete transition to the R3m space group.

- If your primary focus is Electrochemical Optimization: experiment within the calcination window (655°C–800°C) to find the balance between complete recrystallization and grain growth.

Precision in the thermal profile is the difference between a functional powder and a high-performance cathode.

Summary Table:

| Parameter | Role in Phase Formation | Impact on Material Quality |

|---|---|---|

| Atmosphere Control | Provides continuous pure oxygen flow | Stabilizes Ni-ions and ensures phase purity |

| Heating Rate | Precise control at ~0.8°C/min | Prevents thermal stress and preserves nanofiber morphology |

| Temperature Range | 655°C – 800°C calcination windows | Drives R3m crystalline structure and solid-state reaction |

| Thermal Precision | High-accuracy thermal profiling | Prevents structural defects and ensures recrystallization |

Elevate Your Material Research with KINTEK Precision

Unlock superior electrochemical performance for your Ni-rich cathode materials with KINTEK’s high-precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-temperature Tube, Muffle, Rotary, Vacuum, and CVD systems specifically designed to meet the rigorous demands of battery research.

Whether you require ultra-slow heating rates for nanofiber integrity or strict atmospheric control for phase purity, our systems are fully customizable to your unique research needs.

Ready to optimize your synthesis process? Contact us today to speak with a technical expert.

Visual Guide

References

- Soumyadip Mitra, C. Sudakar. High rate capability and cyclic stability of Ni‐rich layered oxide LiNi<sub>0.83</sub>Co<sub>0.12</sub>Mn<sub>0.05−<i>x</i></sub>Al<sub><i>x</i></sub>O<sub>2</sub> cathodes: Nanofiber versus nanoparticle morphology. DOI: 10.1002/bte2.20230066

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a multi-zone furnace work? Achieve Personalized Comfort and Energy Efficiency

- What are the benefits of using a tube furnace in high-stakes research? Unlock Precise Environmental Control for Sensitive Experiments

- How does the positioning of a quartz tube in a vertical tube furnace contribute to the stability of the synthesis reaction?

- What are the different heating methods in tube furnaces and their corresponding temperature ranges?

- What role does a horizontal tube furnace play in the carbonization of SiC-C preforms? Optimize Material Structural Yield

- What advantages does a drop tube furnace offer over other types of furnaces? Unlock Precision in Particle Thermal Analysis

- What is a three-zone tube furnace? Achieve Precise Thermal Control for Advanced Materials Processing

- What is the significance of a multi-zone configuration in a horizontal tube furnace? Master FC-CVD Synthesis Control