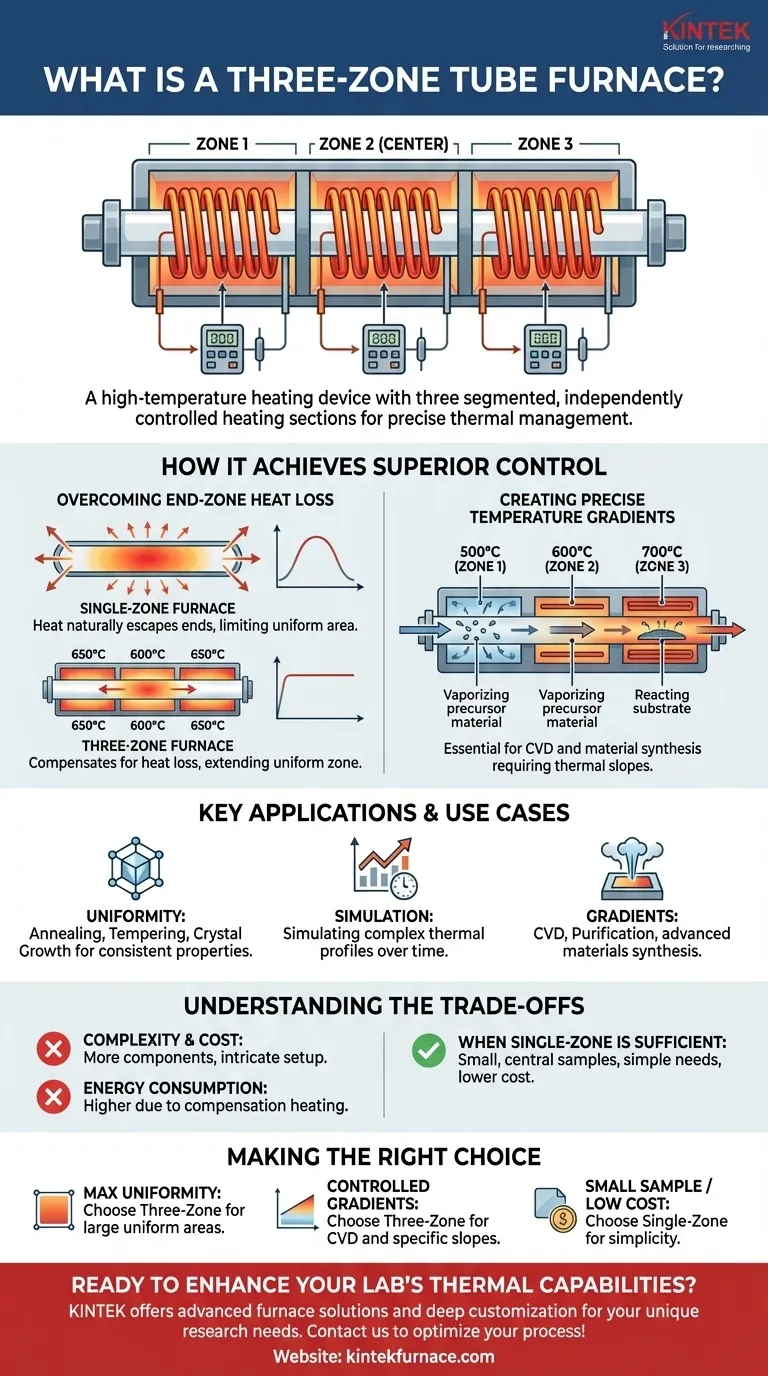

In essence, a three-zone tube furnace is a high-temperature heating device distinguished by its segmented design. Instead of a single heating element, its cylindrical chamber is surrounded by three separate heating sections, each with its own independent temperature controller and sensor. This configuration allows for exceptionally precise thermal management across the length of the furnace tube.

The core advantage of a three-zone furnace is not just heating, but thermal control. It is designed to solve the two primary challenges in high-temperature processing: either creating a perfectly uniform temperature over a large area or intentionally establishing a stable, well-defined temperature gradient.

How a Three-Zone Furnace Achieves Superior Control

The key to the three-zone furnace is its ability to manage temperature in sections rather than as a whole. This granular control unlocks capabilities that single-zone furnaces cannot match.

The Anatomy of Independent Zones

Each of the three zones is a self-contained heating system. It consists of its own heating elements, a dedicated thermocouple (temperature sensor), and an individual controller.

This allows an operator to program a specific temperature setpoint for the center zone and different setpoints for the two end zones.

The Problem of End-Zone Heat Loss

In any tube furnace, heat naturally escapes from the open ends of the tube. A single-zone furnace is therefore only truly uniform in a small area at its absolute center, with temperatures dropping off toward the ends.

A three-zone furnace directly counteracts this. By setting the two outer zones to a slightly higher temperature, you can create a "thermal barrier" that compensates for the heat loss, dramatically extending the length of the truly uniform temperature zone in the middle.

Creating Precise Temperature Gradients

The alternative application is to intentionally create a temperature slope. For example, you can program the zones to 500°C, 600°C, and 700°C respectively.

This is critical for processes like chemical vapor deposition (CVD), where different precursor materials may need to be vaporized at specific temperatures before they travel downstream to react on a substrate in the hotter central zone.

Key Applications and Use Cases

The unique control offered by a three-zone architecture makes it essential for a range of advanced scientific and industrial processes.

Achieving Maximum Temperature Uniformity

For processes like annealing, tempering, or crystal growth, the entire sample must experience the exact same temperature to ensure consistent material properties. A three-zone furnace is the standard for achieving this over a significant sample length.

Simulating Complex Thermal Profiles

Researchers can program the furnace to change the temperature in different zones over time, simulating complex real-world conditions or performing sophisticated materials synthesis that requires precise thermal ramps and soaks.

Advanced Materials Synthesis

Processes like chemical vapor deposition and purification rely on the ability to control temperature gradients. A three-zone furnace provides the necessary control to optimize vapor pressures and reaction kinetics along the length of the tube.

Understanding the Trade-offs

While powerful, a three-zone furnace is not always the necessary choice. Understanding its trade-offs is key to making a sound investment.

Complexity and Cost

The presence of three controllers, three sets of heating elements, and three thermocouples makes the device inherently more complex and expensive than its single-zone counterpart. Programming and setup also require more attention.

When a Single-Zone Furnace Is Sufficient

If your process only requires heating a very small sample placed directly in the center of the furnace, a single-zone model may provide a sufficiently uniform hot zone for your needs. For simpler applications, the cost and complexity of a three-zone system may be unnecessary.

Energy Consumption

To achieve maximum uniformity, the end zones are often run at a higher temperature than the target process temperature. This compensation, while effective, can lead to higher overall energy consumption compared to a single-zone furnace running at the same central temperature.

Making the Right Choice for Your Goal

Selecting the right furnace depends entirely on the thermal precision your process demands.

- If your primary focus is achieving the largest possible uniform temperature zone: A three-zone furnace is the correct tool, as it is specifically designed to compensate for heat loss at the ends of the tube.

- If your primary focus is creating a controlled temperature gradient for processes like CVD: A multi-zone furnace is essential for setting the distinct, stable temperature points required along the process tube.

- If your primary focus is heating a small, central sample where cost and simplicity are major factors: A single-zone furnace often provides a sufficient and more economical solution.

Understanding this principle of zonal control empowers you to select the precise thermal processing tool for your specific scientific or industrial goal.

Summary Table:

| Feature | Description |

|---|---|

| Design | Cylindrical chamber with three independent heating zones, each with its own controller and sensor |

| Key Advantage | Precise thermal management for uniform heating or defined temperature gradients |

| Primary Applications | Chemical vapor deposition (CVD), annealing, crystal growth, materials synthesis |

| Trade-offs | Higher complexity, cost, and energy consumption compared to single-zone furnaces |

Ready to enhance your lab's thermal processing capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Whether you're working on materials synthesis, CVD, or other precision applications, our three-zone tube furnaces can deliver the control and performance you need. Contact us today to discuss how we can help optimize your processes and achieve superior results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control